Preparation method of high density BaTi2O5 bulk

A dense and powder technology, applied in the field of preparation of high-density BaTi2O5 ceramic blocks, can solve the problems of small size (usually only a few microns to a few millimeters, difficult to meet application requirements, adverse effects on product performance, etc.) Abnormal growth, short sintering time, fine grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of highly dense BaTi 2 o 5 The preparation method of ceramic block, it comprises the following steps:

[0025] 1) by BaCO 3 and TiO 2 BaTi Prepared by Mixed Powder Arc Melting 2 o 5 Raw material powder, BaCO 3 with TiO 2 The molar ratio of 1:2, without adding any sintering aid, BaTi 2 o 5 The average particle size of the raw material powder is 40 μm;

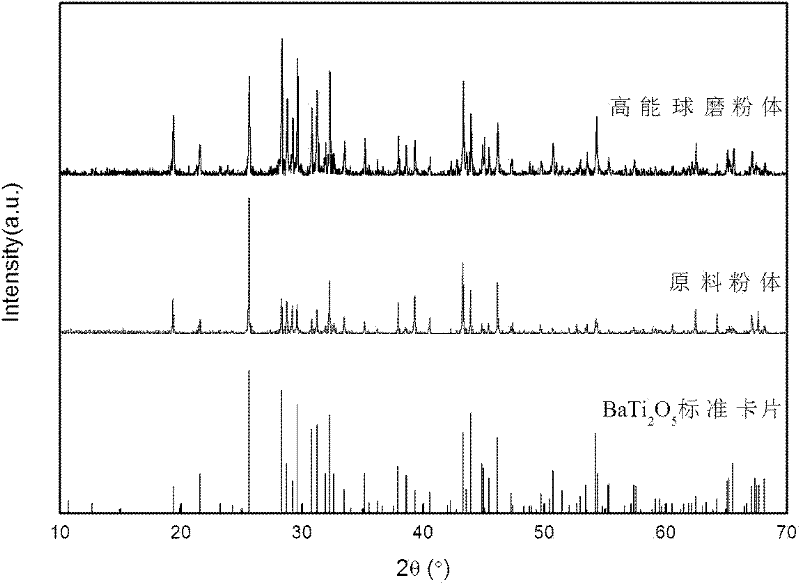

[0026] Will BaTi 2 o 5 The raw material powder is put into a planetary high-energy ball mill for grinding. The material of the grinding ball is agate, the grinding medium is absolute ethanol, the ratio of ball to material is 6:1, the ball milling time is 20h, and the rotation speed is 300r / min to obtain BaTi 2 o 5 Micropowder; said BaTi 2 o 5 The phase of the micropowder is single, with an average particle size of 7 μm;

[0027] 2) Add 6.4g of BaTi 2 o 5The micropowder is placed in a graphite mold, and the whole is moved into a spark plasma sintering furnace, and the vacuum (10 -3 ) at a rate of 1...

Embodiment 2

[0031] A kind of highly dense BaTi 2 o 5 The preparation method of ceramic block, it comprises the following steps:

[0032] 1) by BaCO 3 and TiO 2 BaTi prepared by mixed powder arc melting 2 o 5 Raw material powder, BaCO 3 with TiO 2 The molar ratio of 1:2, without adding any sintering aid, BaTi 2 o 5 The average particle size of the raw material powder is 40 μm;

[0033] Will BaTi 2 o 5 The raw material powder is put into a planetary high-energy ball mill for grinding. The material of the grinding ball is agate, the grinding medium is absolute ethanol, the ratio of ball to material is 3:1, the ball milling time is 15h, and the speed is 200r / min to obtain BaTi 2 o 5 Micropowder; said BaTi 2 o 5 The micropowder has a single phase, with an average particle size of 18 μm;

[0034] 2) Add 14.5g of BaTi 2 o 5 The micropowder is placed in a graphite mold, and the whole is moved into a spark plasma sintering furnace, and the vacuum (10 -2 ) at a rate of 80 °C / min t...

Embodiment 3

[0037] A kind of highly dense BaTi 2 o 5 The preparation method of ceramic block, it comprises the following steps:

[0038] 1) the BaTi 2 o 5 The raw material powder is put into a planetary high-energy ball mill for grinding. The material of the grinding ball is agate, the grinding medium is absolute ethanol, the ball-to-material ratio is 10:1, the ball milling time is 25h, and the speed is 400r / min to obtain BaTi 2 o 5 Micropowder; said BaTi 2 o 5 The phase of the micropowder is single, with an average particle size of 5 μm;

[0039] 2) Add 1.8g of BaTi 2 o 5 The micropowder is placed in a graphite mold, and the whole is moved into a spark plasma sintering furnace, and the vacuum (10 -1 Pa) at a rate of 150 °C / min to 1100 °C, hold for 15 min, and apply an axial pressure of 60 MPa, and then cool to room temperature with the furnace to obtain BaTi 2 o 5 Sintered body;

[0040] 3) the BaTi 2 o 5 The sintered body was placed in a box-type electric furnace, and in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com