Ion implantation device and adjustment method of beam current density distribution

An ion implantation device and density distribution technology, applied in circuits, discharge tubes, electrical components, etc., can solve complex, undisclosed, long-term and other problems, and achieve the effect of efficient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

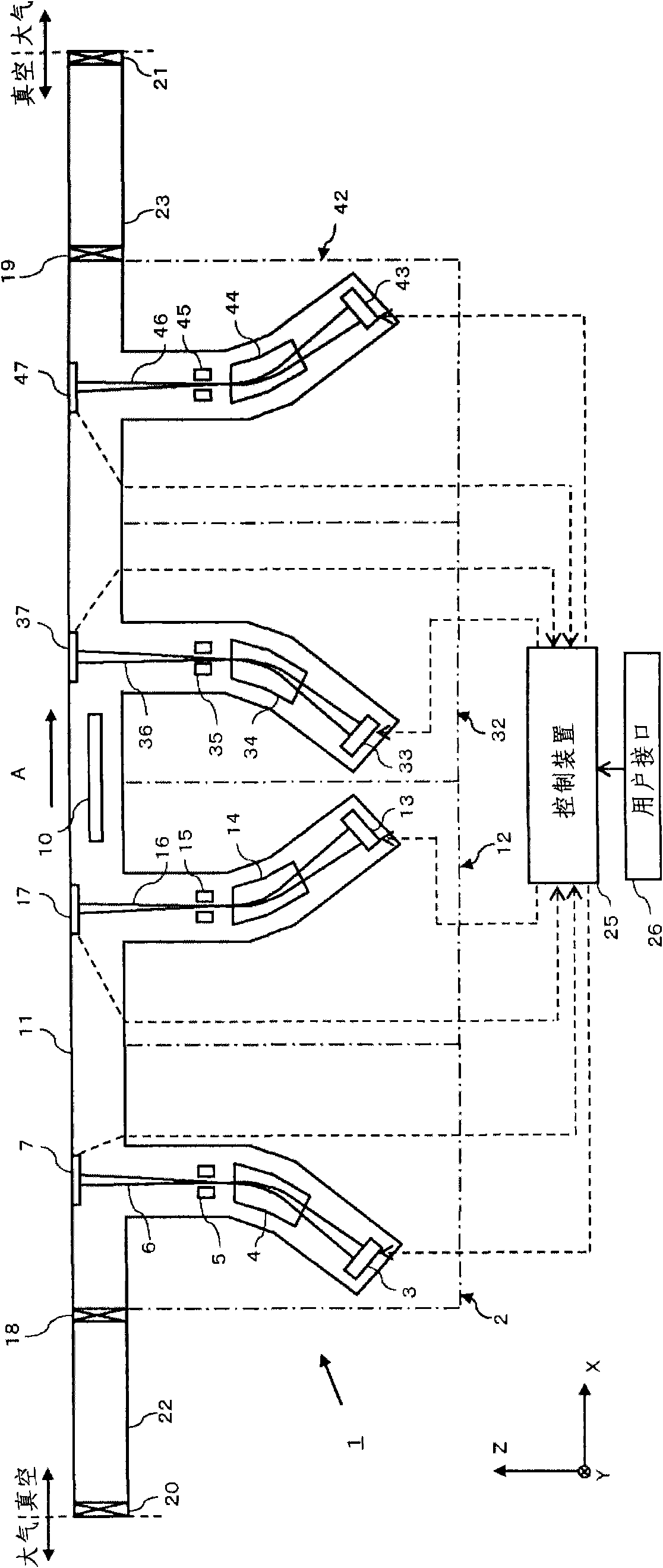

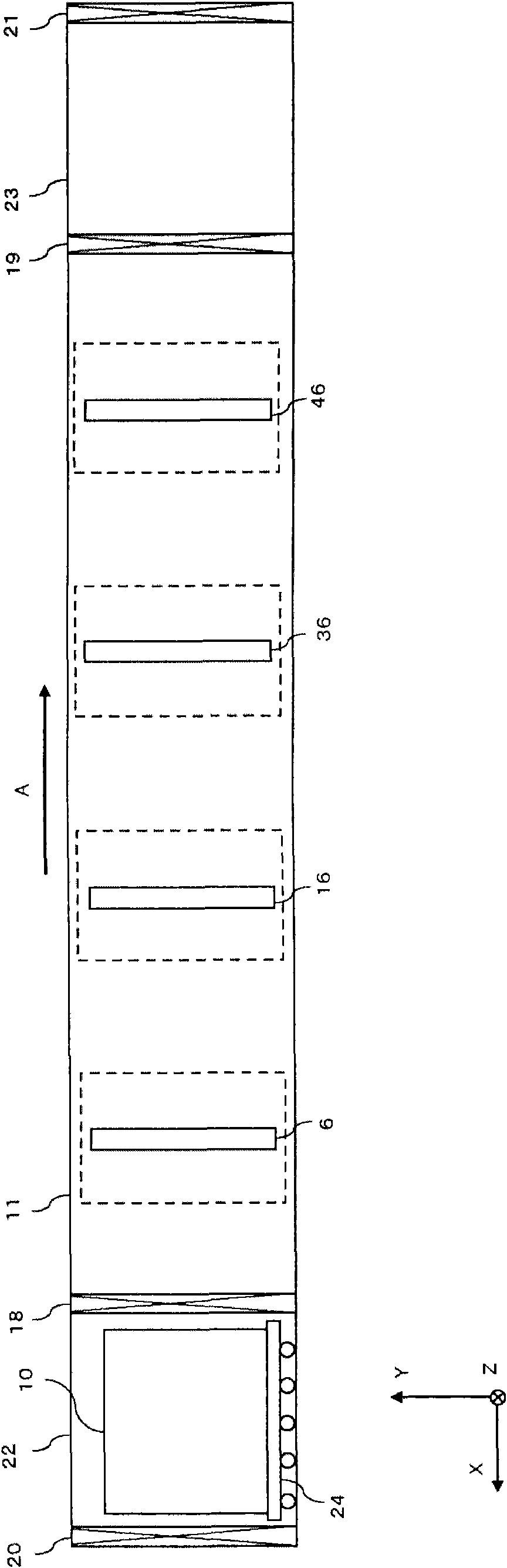

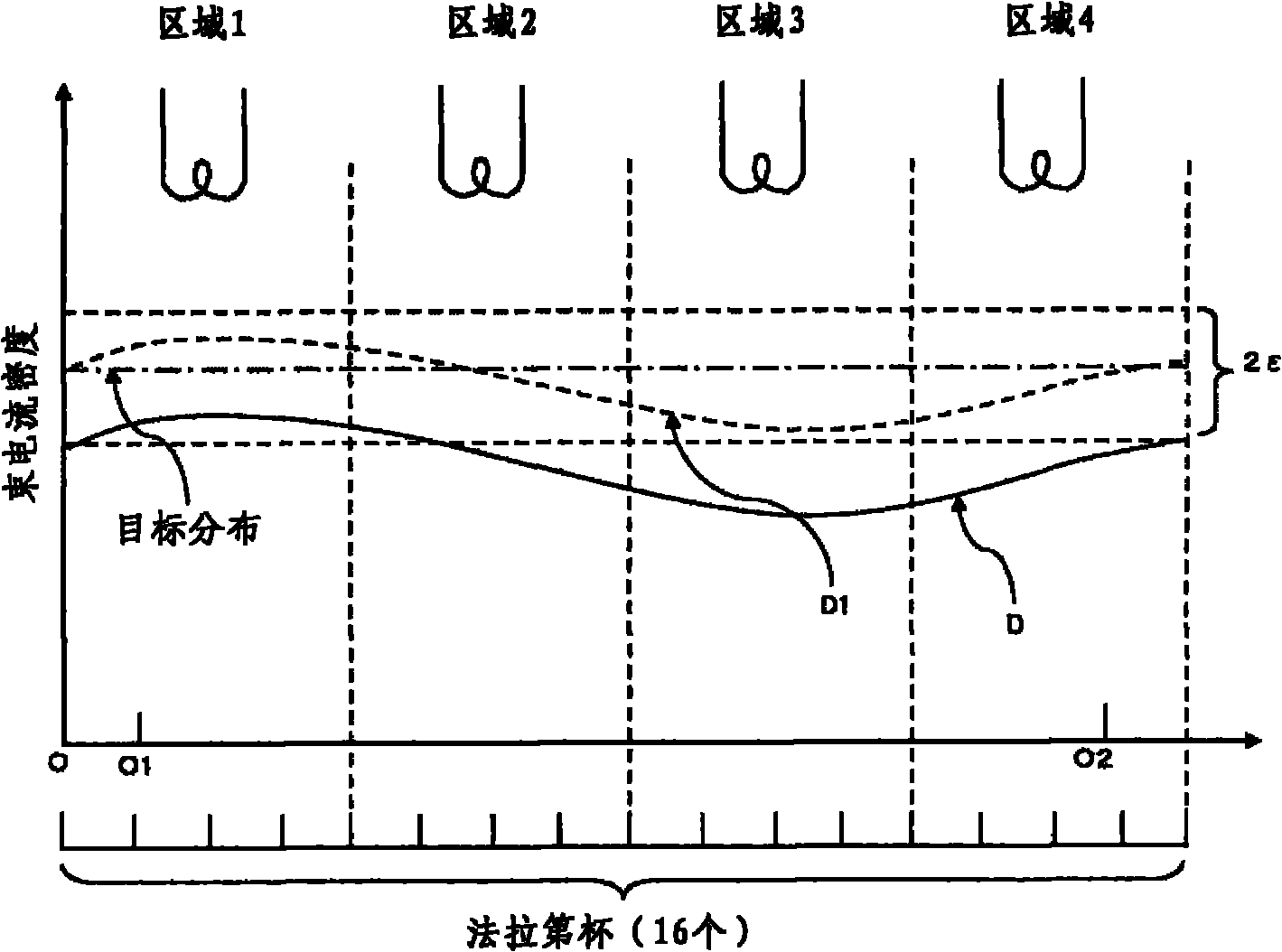

[0043] figure 1 It is a plan view showing an ion implantation apparatus 1 according to an embodiment of the present invention. figure 2 is viewed from the Z direction figure 1 Plan view of the interior of the processing chamber. Hereinafter, the overall structure of an ion implantation apparatus according to an embodiment of the present invention will be described with reference to these drawings.

[0044] In the present invention, the X direction is used as the transport direction of the substrate, the Y direction is used as the longitudinal direction of the ion beam, and the Z direction is used as the traveling direction of the ion beam irradiated on the glass substrate in the processing chamber, and these directions are mutually perpendicular. In addition, in the present invention, "ribbon-shaped ion beam" refers to an ion beam whose cross section is substantially rectangular when the ion beam is cut by a plane perpendicular to the traveling direction of the ion beam. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com