Plasma processing apparatus and plasma processing method

A plasma and processing device technology, applied in the field of plasma processing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Various exemplary embodiments are described below.

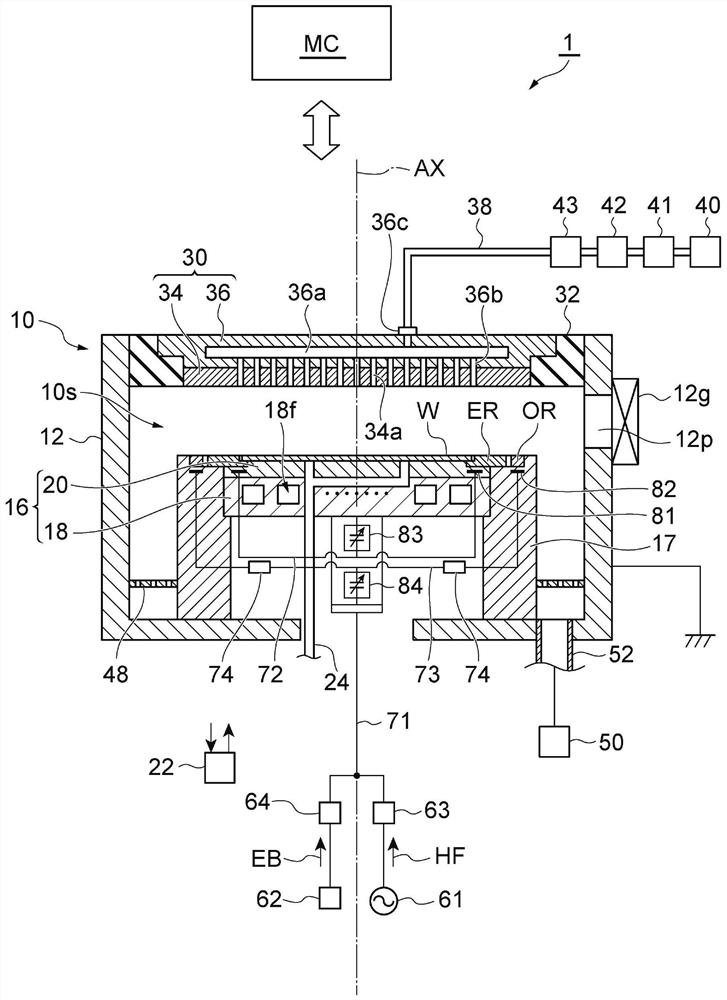

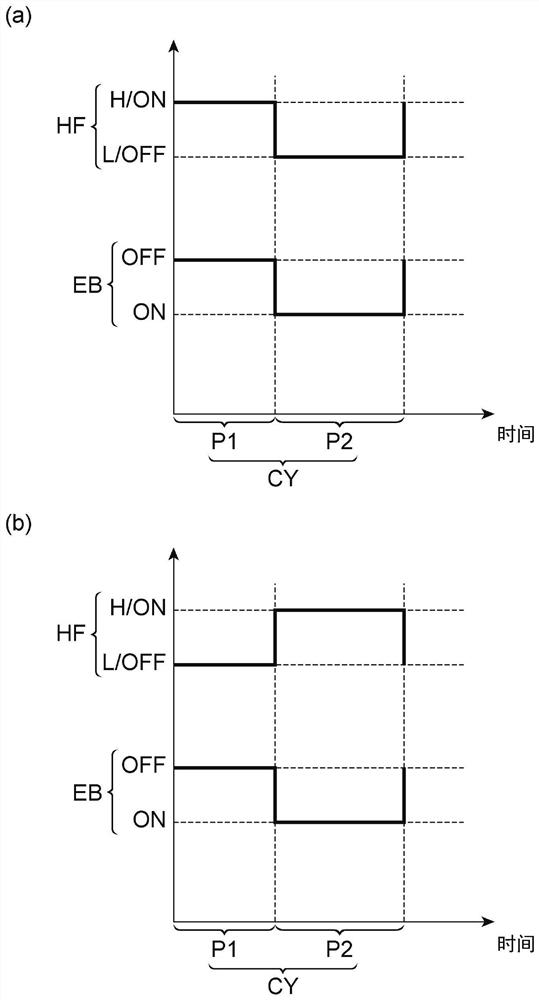

[0016] In an exemplary embodiment, a plasma processing apparatus is provided. A plasma processing apparatus includes a chamber, a substrate holder, a high-frequency power supply, and a bias power supply. The substrate holder has bias electrodes. The high-frequency power supply is configured to generate high-frequency power to be supplied to the high-frequency electrode in order to generate plasma above the substrate supported by the substrate holder in the chamber. The bias power supply is connected to the bias electrode via an electrical path. The edge ring is mounted on the substrate holder. The edge ring is electrically connected to a bias power supply, or to another bias power supply, via an impedance adjuster providing a variable impedance between the bias electrode and the edge ring or between the electrical path and the edge ring. The outer ring extends radially and on the outside with respect to the edge r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com