Radiation sensitivity resin composition for display element, interlayer insulation film, protective film and spacer and forming method thereof

A technology of resin composition and display element, which is applied in the field of protective film, spacer, and interlayer insulating film, can solve the problems of heating, inability to solve the problem of low linear expansion of cured film, improvement of voltage holding ratio, inability to form fine pattern, etc. Achieving the effect of high radiation sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0121]

[0122]The radiation-sensitive resin composition of the present invention can be prepared by adding the above-mentioned (A) polymer, (B) ethylenically unsaturated compound, (C) radiation-sensitive polymerization initiator and (D) compound, and other components optionally added above. Mix well to prepare. This radiation-sensitive resin composition is preferably used in a solution state by being dissolved in an appropriate solvent. For example, by combining (A) polymer, (B) polymerizable unsaturated compound, (C) radiation-sensitive polymerization initiator, (D) compound, and optionally added (E) epoxy resin having two or more in one molecule Ethyl compound, (F) Adhesion aid, (G) Surfactant, (H) Storage stabilizer, (I) Heat resistance improver are mixed in a solvent at a predetermined ratio to prepare a solution state radiation-sensitive resin composition.

[0123] As the solvent used in the preparation of the radiation-sensitive resin composition of the present inve...

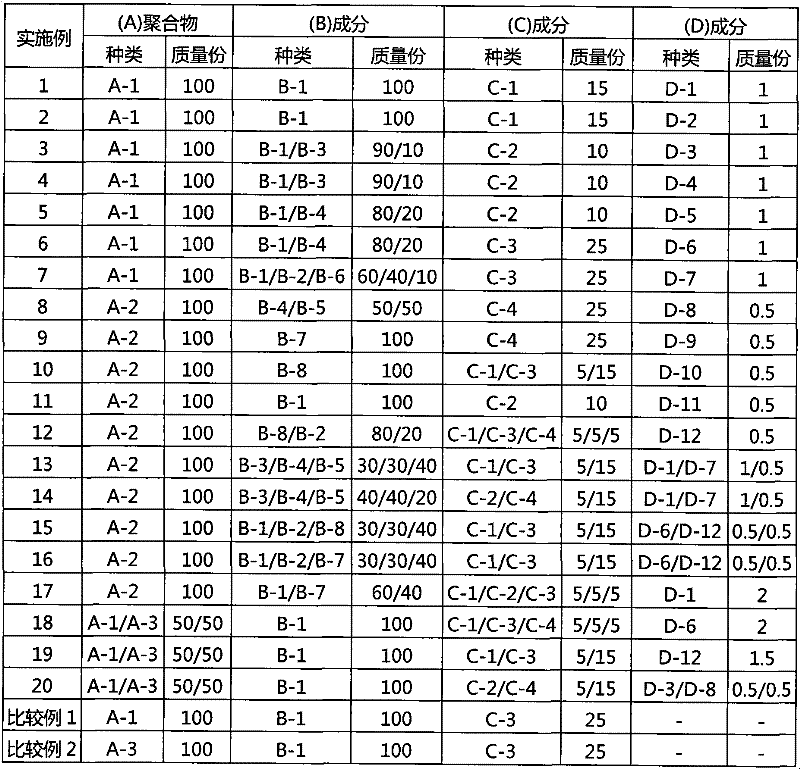

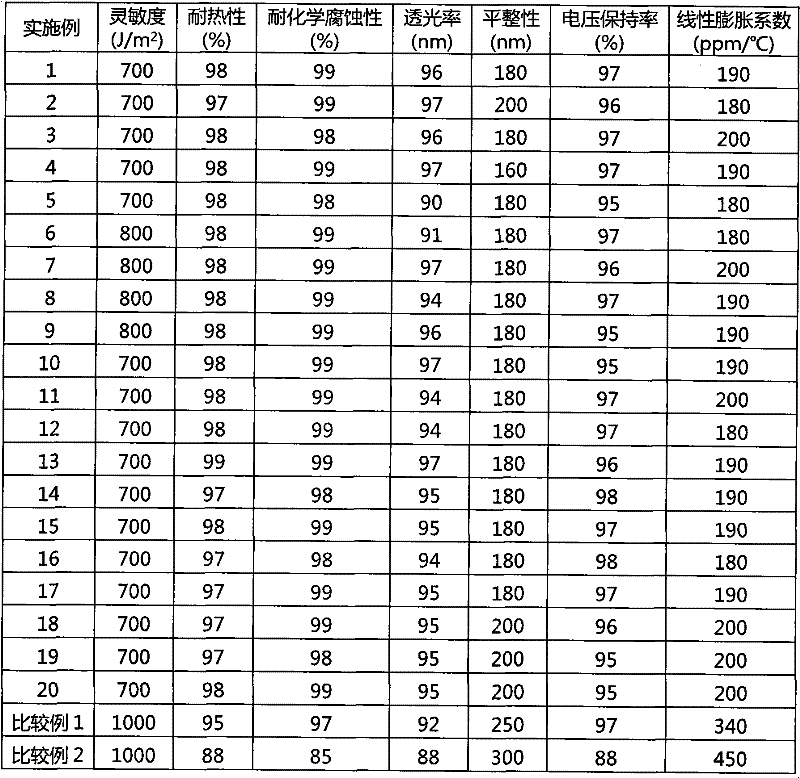

Embodiment

[0165] Hereinafter, synthesis examples and examples are shown to describe the present invention more specifically, but the present invention is not limited to these synthesis examples and examples.

[0166]

Synthetic example 1

[0168] In a flask with a condenser tube and a stirrer, add 5 parts by mass of 2,2'-azobis(2,4-dimethylvaleronitrile) and 220 parts by mass of diethylene glycol methyl ethyl ether, and then Add 20 parts by mass of styrene, 12 parts by mass of methacrylic acid, 28 parts by mass of methacrylic acid tricyclic [5.2.1.0 2,6 ]decyl-8-yl ester and 40 parts by mass of glycidyl methacrylate, nitrogen replacement, while slowly stirring, the temperature of the solution was raised to 70°C, and the temperature was kept for 5 hours to polymerize, to obtain a copolymer containing ( A-1) solution. The solid content concentration (ratio of the polymer mass to the total mass of the polymer solution) of the obtained polymer solution was 31.3%, and the weight average molecular weight Mw of the copolymer (A-1) was 12,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com