Radiation-sensitive resin composition, interlayer insulating film and method for forming the same

A resin composition, interlayer insulating film technology, applied in the application of radiation from radiation sources, photosensitive materials for optomechanical equipment, instruments, etc., can solve problems such as heating, inability to form patterns, etc. Excellent effect of solvent resistance and relative permittivity

Inactive Publication Date: 2010-10-13

JSR CORPORATIOON

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Synthetic example 1

Synthetic example 2

Synthetic example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

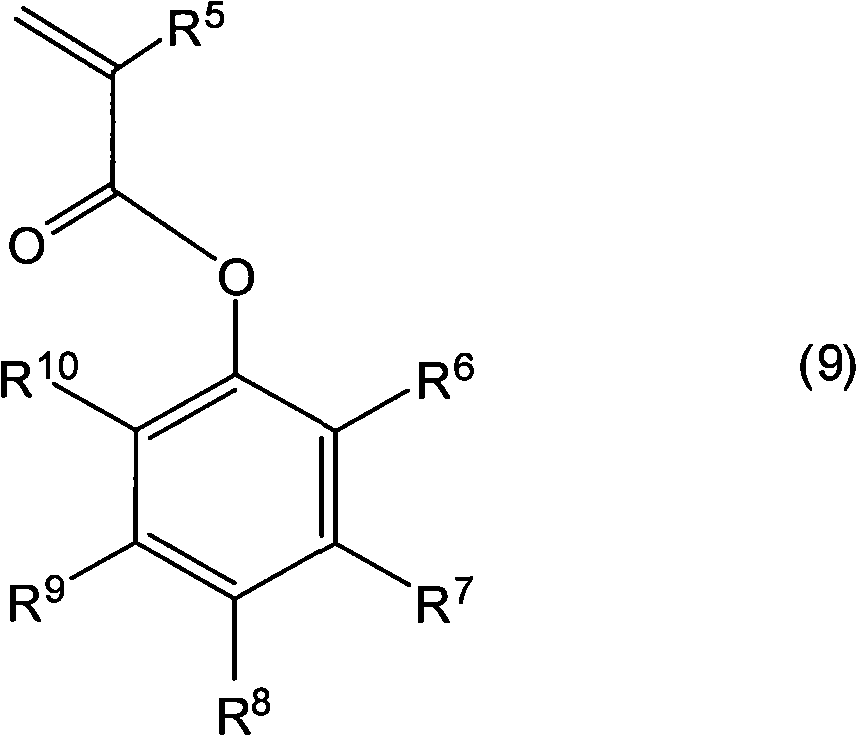

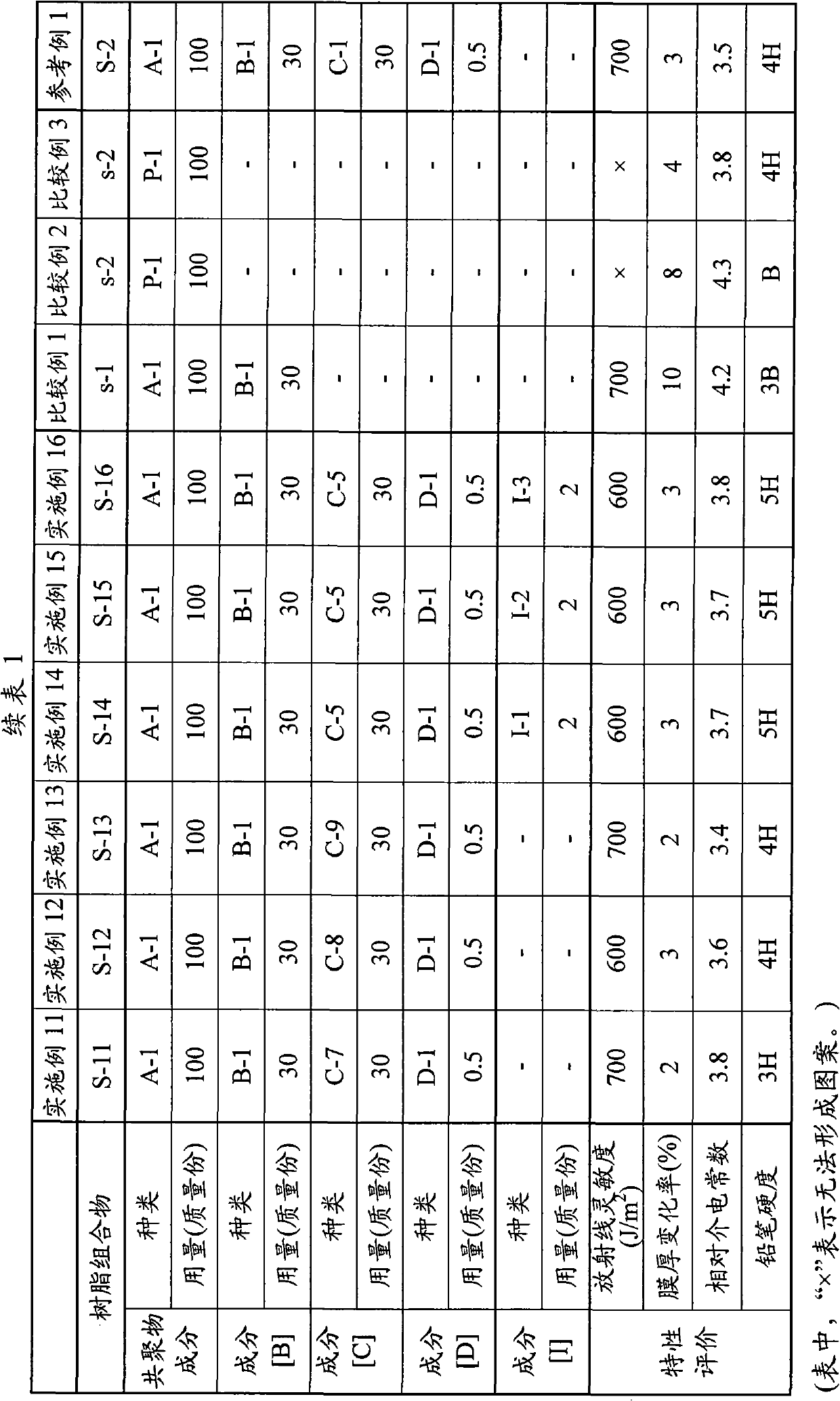

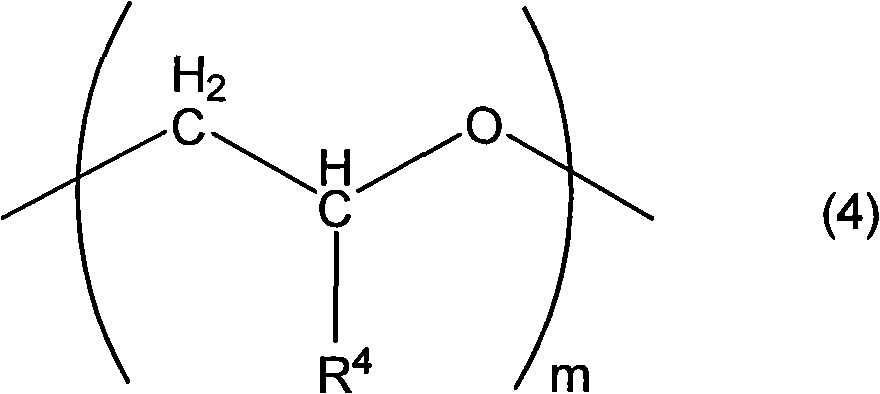

The present invention relates to a radiation-sensitive resin composition, an interlayer insulating film and method for forming the same. The present invention provides the interlayer insulating film which is suitable for being used for a flexible display. Furthermore the radiation-sensitive resin composition can be heated at a low temperature in a short time for burning and simultaneously has high radiation sensitivity. The radiation-sensitive resin composition for forming interlayer insulating film according to the invention comprises the following components: [A] copolymer base soluble resin which is formed by the polymerization of monomer comprising (a1) unsaturated carboxylic acid and / or unsaturated carboxylic anhydride and (a2) unsaturated compound with epoxy group; [B] 1,2-quinonediazide compound and [C] a compound with more than two hydrosulfuryls in one module; wherein the component [C] with more than two hydrosulfuryls in more module is preferably a compound represented by the formula (1).

Description

technical field The present invention relates to a radiation-sensitive resin composition suitable for forming an interlayer insulating film of a flexible display, an interlayer insulating film formed from the composition, and a method for forming the same. Background technique In recent years, due to improvements in convenience such as weight reduction and miniaturization, flexible displays such as liquid crystal electronic papers have become popular. As substrates for such flexible displays, plastic substrates such as polycarbonate and polyethylene terephthalate have been studied instead of glass substrates. However, these plastics have a problem of being slightly stretched and shrunk when heated, which affects the functions of the display, so improvement of heat resistance is urgently required. On the other hand, in order to reduce the thermal stress applied to the plastic substrate, it is also studied to lower the temperature of the manufacturing process of the flexible ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G03F7/008G03F7/012G03F7/00

CPCG03F7/023G03F7/033H01L27/1248H01L29/7842Y10S430/1055

Inventor 西信弘米田英司饭田雅史丸山拓之滨田谦一

Owner JSR CORPORATIOON

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com