Manufacturing method of starting sheet for nickel electrolysis

A technology for starting pole pieces and nickel electrolysis, which is applied in the field of preparation of starting pole pieces for nickel electrolysis extraction or electrorefining, can solve the problem of not having the effect of continuously preparing nickel starting pole pieces, being unsuitable for nickel starting pole pieces, and toxic oxides. and other problems, to achieve the effect of dimensional stability, smooth appearance and good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

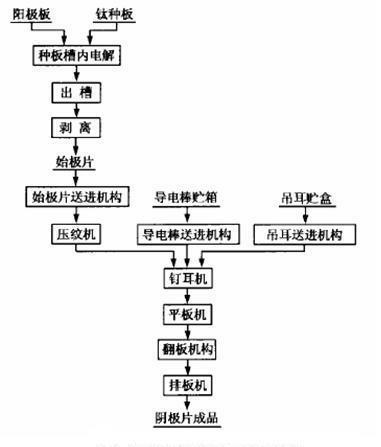

Image

Examples

Embodiment 1

[0027] (1) The width of the 5 layers is 1020mm, the thickness is 1.35mm, and the surface density is 355 g m -2 The nickel foam is stacked together, and the bright and non-porous metal nickel sheet is made by rolling equipment;

[0028] (2) Cut the rolled thin plate into rectangular blocks of 1000mm×780mm (the tabs are also cut with the same thin plate);

[0029] (3) Weld the lugs with a spot welding machine, which becomes the starting pole piece.

Embodiment 2

[0031] (1) The width of the two layers is 1020mm, the thickness is 2.5mm, and the surface density is 780 g m -2 The nickel foam is stacked together, and the bright and non-porous metal nickel sheet is made by rolling equipment;

[0032] (2) Slitting the rolled sheet into inverted trapezoidal blocks with a height of 1000 mm, an upper bottom of 820 mm, and a lower bottom of 760 mm (the tabs are cut using the sheet in Example 1);

[0033] (3) Weld the lugs with a spot welding machine, which becomes the starting pole piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com