Method for producing rare-earth isoprene butadiene rubber

A technology of butylene rubber and production method, which is applied to tire parts, transportation and packaging, special tires, etc., can solve the problems of recycling monomers and low purity of solvents, achieve easy mixing and processing, reduce production energy consumption, and reduce Effect on overall production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

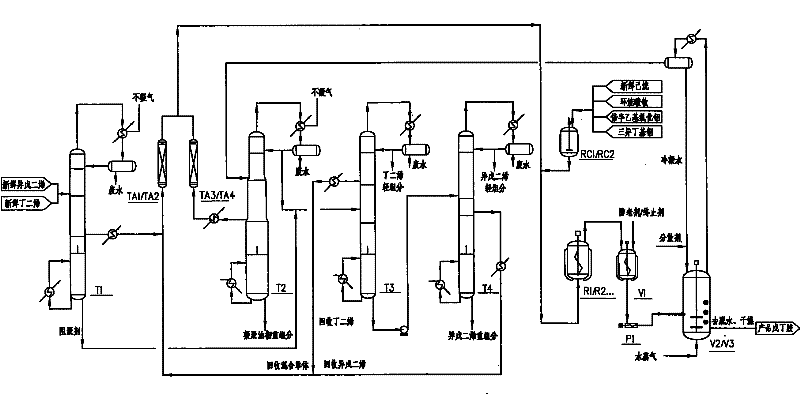

Image

Examples

Embodiment 1

[0068] Embodiment 1, this embodiment belongs to the small-scale test in the laboratory.

[0069] Mix 921g (13.5mol) of industrial polymer grade isoprene (see Table 1-1 for composition) and 183g (3.4mol) of industrial polymer grade 1,3-butadiene (see Table 1-2 for composition) Finally, use an ordinary distillation device to distill off dissolved oxygen, dimers and polymerization inhibitor p-tert-butylcatechol, so that the dissolved oxygen content is less than 0.0005%, the dimer content is less than 0.005%, and the polymerization inhibitor content is less than 0.0001%. .

[0070] Then, use dry spherical alumina and molecular sieves to soak until the water content is less than 0.002% under the protection of high-purity nitrogen to obtain 1000 g of refined mixed monomers, and the molar ratio of isoprene to butadiene is 4:1.

[0071] Soak 6000g of industrial hexane (see Table 1-3 for composition) with dry spherical alumina and molecular sieves until the water content is less than ...

Embodiment 2

[0085] Embodiment 2, this embodiment belongs to the intermediate scale-up test.

[0086] 460.3 (6.77kmol) of industrial polymer grade isoprene (see Table 1-1 for composition) and 91.4kg (1.7kmol) of industrial polymer grade 1,3-butadiene (see Table 1-2 for composition) After mixing, use a tower with an internal diameter of 400 mm and a packing height of 10 m to intermittently distill, and extract 540 kg of a mixture of isoprene and butadiene from a packing height of 2 m, and the molar ratio of isoprene and butadiene is 4:1. Its moisture is 0.01%, dimer is 0.005%, and polymerization inhibitor p-tert-butylcatechol is 0.0001%. Then the mixture is sequentially passed through two adsorption drying towers respectively equipped with spherical alumina and spherical molecular sieves to obtain 530 kg of refined mixed monomers with a water content of less than 0.002%.

[0087] 1000kg of industrial hexane (see Table 1-3 for composition) was intermittently distilled to a water content of ...

Embodiment 3

[0094] Embodiment 3, this embodiment belongs to the technology that can be directly applied to industrial production after the data of the small test and the pilot test are enlarged by the project.

[0095] Fresh polymer grade isoprene industrial product (composition see Table 1-1) 3222.1kg / h (47.38kmol / h) and fresh polymer grade 1,3-butadiene industrial product (composition see Table 1-2) 639.8kg / h (11.9kmol / h) is mixed online and added to the fresh monomer rectification tower T1 to remove dissolved oxygen, water, dimers and inhibitor p-tert-butylcatechol. The number of valve trays of the fresh monomer distillation column T1 is 45, the feed is located at the 35th valve tray (starting from the bottom of the tower, the same below), and the side line extraction is located at the 7th valve tray. Full reflux is used. The dissolved oxygen of the mixed monomer extracted from the side line is less than 0.0005%, the water content is 0.01%, the dimer is 0.005%, and the polymerization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com