Vacuum insulation panel and preparation method and application thereof

A vacuum insulation panel and vacuuming technology, applied in applications, heat exchange equipment, other household appliances, etc., can solve problems such as affecting building quality, affecting vacuum degree, and long vacuuming time, achieving process tact optimization and improving production efficiency. , the effect of reducing the loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

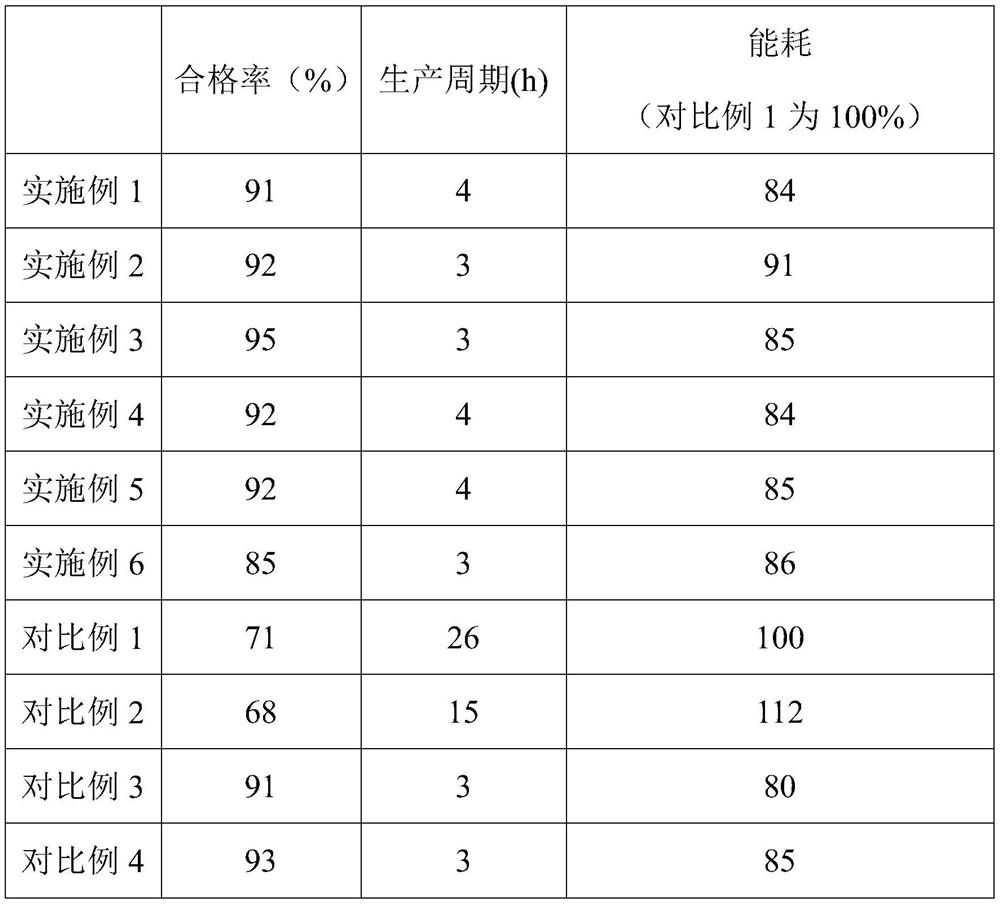

Examples

Embodiment 1

[0048] A method for preparing a vacuum insulation panel, the method comprising the steps of:

[0049] (1) Dry glass fiber mat and silica powder at 180°C for 1 hour to obtain glass fiber mat and silica powder with a water content of 0.4%; 70 parts by weight of dried glass fiber mat (50 μm in diameter, Weifang Sanyu New Material Co., Ltd.), 30 parts by weight of dried silicon dioxide powder (Nanjing Baoket New Material Co., Ltd.) and 5 parts by weight of hot melt adhesive (EVA type hot melt adhesive, melting point is 60 ° C) mixed, Put it under a hydraulic press and press it under a pressure of 2Mpa, and then cut it into a core material of 400×600mm;

[0050] (2) Put the core material obtained in step (1) in a barrier packaging bag, vacuumize it so that the vacuum degree is 20Pa, heat seal it, heat it in an oven at 110°C for 0.1h, cool and solidify, and obtain the vacuum insulation panel .

Embodiment 2

[0052] A method for preparing a vacuum insulation panel, the method comprising the steps of:

[0053] (1) Dry glass fiber mat and silica powder at 230°C for 0.5h to obtain glass fiber mat and silica powder with a moisture content of 0.5%; 70 parts by weight of dried glass fiber mat (50 μm in diameter, Weifang Sanyu New Material Co., Ltd.), 30 parts by weight of dried silica powder (Nanjing Baoket New Material Co., Ltd.) and 10 parts by weight of hot melt adhesive (TPU type hot melt adhesive, melting point is 68 ° C) mixed , Put it under the hydraulic press and press it under the pressure of 2Mpa, and then cut it into the core material of 400×600mm;

[0054] (2) Put the core material obtained in step (1) in a barrier packaging bag, vacuumize to a vacuum degree of 0.1 Pa, heat seal, and heat-treat in an oven at 90° C. for 2 hours to obtain the vacuum insulation panel.

Embodiment 3

[0056] A method for preparing a vacuum insulation panel, the method comprising the steps of:

[0057] (1) Dry glass fiber mat and silica powder at 190°C for 1 hour to obtain glass fiber mat and silica powder with a water content of 0.4%; 70 parts by weight of dried glass fiber mat (50 μm in diameter, Weifang Sanyu New Material Co., Ltd.), 30 parts by weight of dried silicon dioxide powder (Nanjing Baoket New Material Co., Ltd.) and 7.5 parts by weight of hot melt adhesive (TPU type hot melt adhesive, melting point is 68 ° C) mixed, Put it under a hydraulic press and press it under a pressure of 3Mpa, and then cut it into a core material of 400×600mm;

[0058] (2) Put the core material obtained in step (1) in a barrier packaging bag, vacuumize to a vacuum degree of 10 Pa, heat seal, and heat-treat in an oven at 100° C. for 1 hour to obtain the vacuum insulation panel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com