Nano-cavity laser of molecule-doped thin film layer with electroexcitation

An electro-excitation, thin-film layer technology, applied in the field of lasers, can solve the problems of difficult manufacturing process, high cost, difficulty in electro-excitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

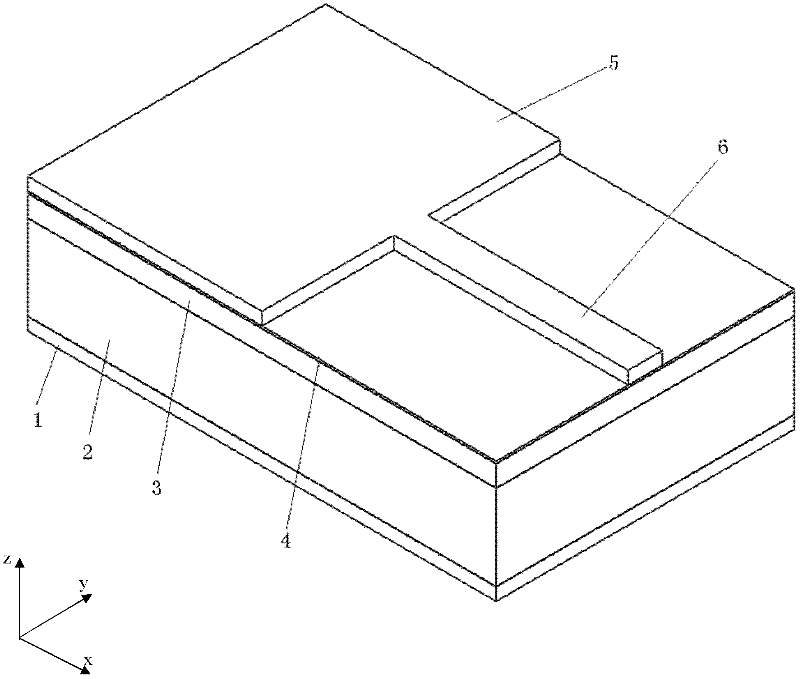

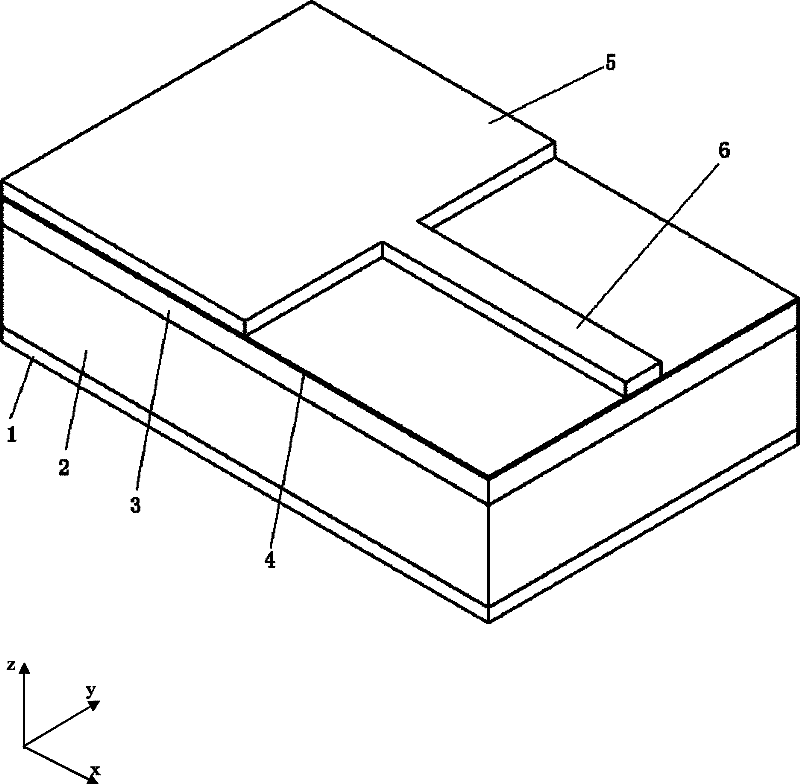

[0012] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 Shown: electro-excited molecule-doped thin-film layer nanocavity laser, including p-face electrode 1, substrate 2, electroluminescence medium 3, molecule-doped thin-film layer 4, n-face electrode 5 and nanowire structure 6; substrate Electroluminescence medium 3, molecular doped thin film layer 4, n-face electrode 5 and nanowire structure 6 are sequentially grown on the top of substrate 2, and p-face electrode 1 is plated on the bottom of substrate 2.

[0014] The molecular doped thin film layer 4 has very little loss to electromagnetic field propagation, the dielectric constant of the thin film layer is smaller than that of the electroluminescent medium, and the ratio d / n of its thickness d to the refractive index n of the thin film layer is less than 50nm, forming a nanocavity structure. The molecules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com