Ball bladder multi-ferrule bearing with reducing middle-layer ferrule

An intermediate layer and ferrule technology, which is applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of small axial bearing capacity, increase the center of gravity difference, and reduce frictional resistance, so as to improve bearing capacity and reduce frictional resistance. Diameter, the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

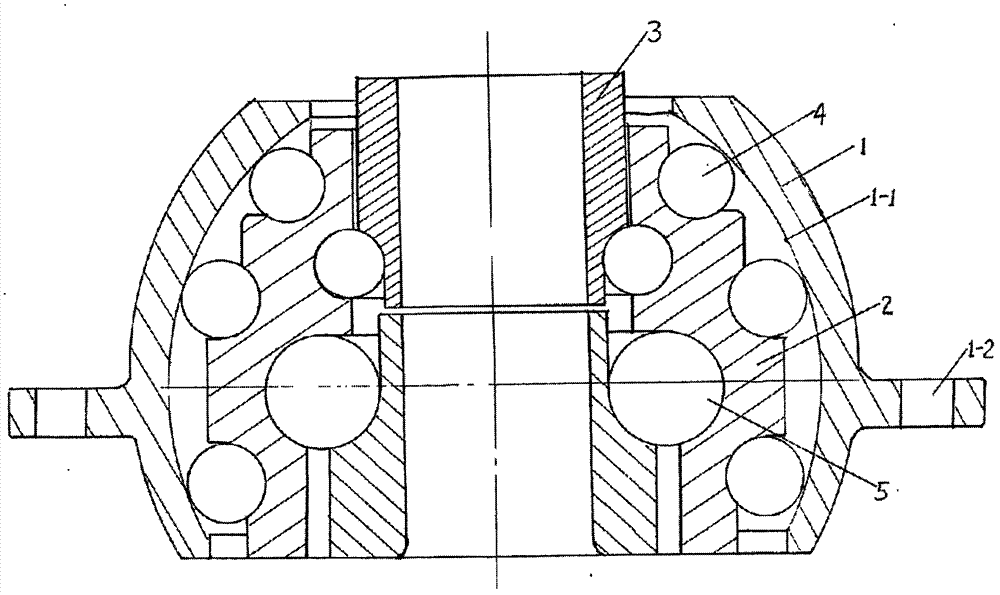

[0031] Such as figure 1 A ball bladder multi-ring bearing with a diameter-reducing intermediate layer ferrule is shown, which consists of a bladder type outer ring 1, a diameter-reducing intermediate layer ferrule 2, two inner ferrules 3, inner rolling elements 5 and The outer rolling body is composed of 4, and the outer circumference of the two inner rings is provided with track grooves 3-1, and shaft mounting holes are respectively opened at the upper and lower ends of the axis line of the outer ring of the bladder type, and there are 3 rows of outer rolling bodies. The inner track of the bladder outer ring is a circular bladder inner track, and the diameter of the axial load-bearing end of the inner track of the bladder is small to ensure that the axial contact angle between the inner track and the rolling body is 50 degrees. There are mounting screw holes 1-2 on it.

[0032] Among them, the variable diameter intermediate layer ferrule 2 is as Figure 4 The axial section ...

Embodiment 2

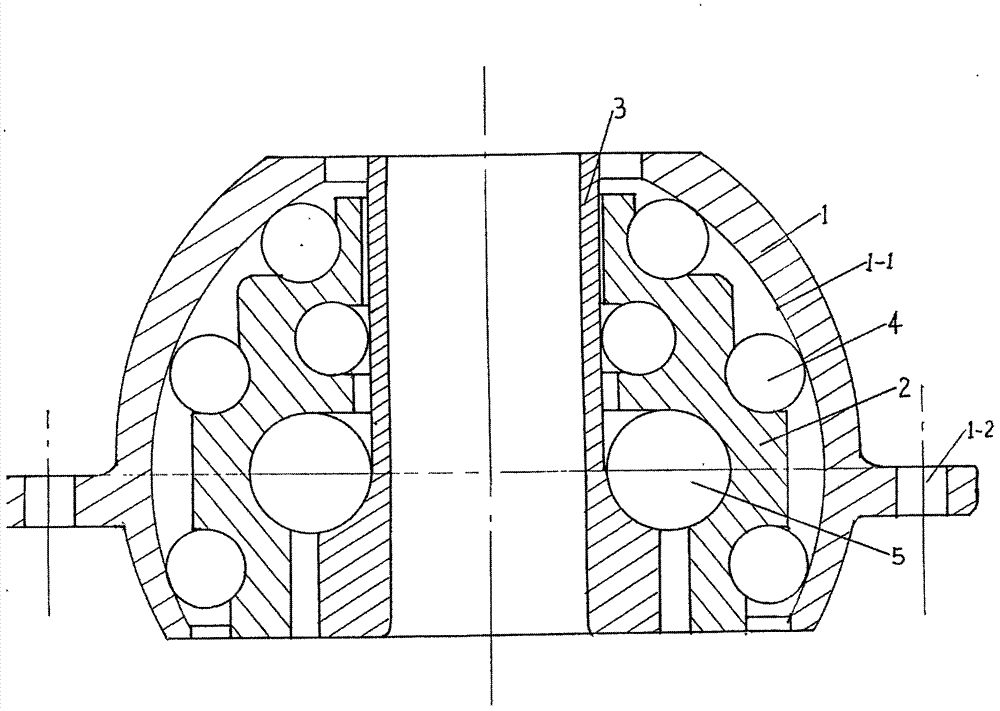

[0034] Such as figure 2 The shown a kind of ball bladder multi-ring bearing provided with a variable-diameter intermediate layer ring has the same basic structure as that of Embodiment 1, except that the inner ring is an inner ring (such as Figure 5 ). The bearings of Examples 1 and 2 are particularly suitable for steam jet engine aircraft worm fans.

Embodiment 3

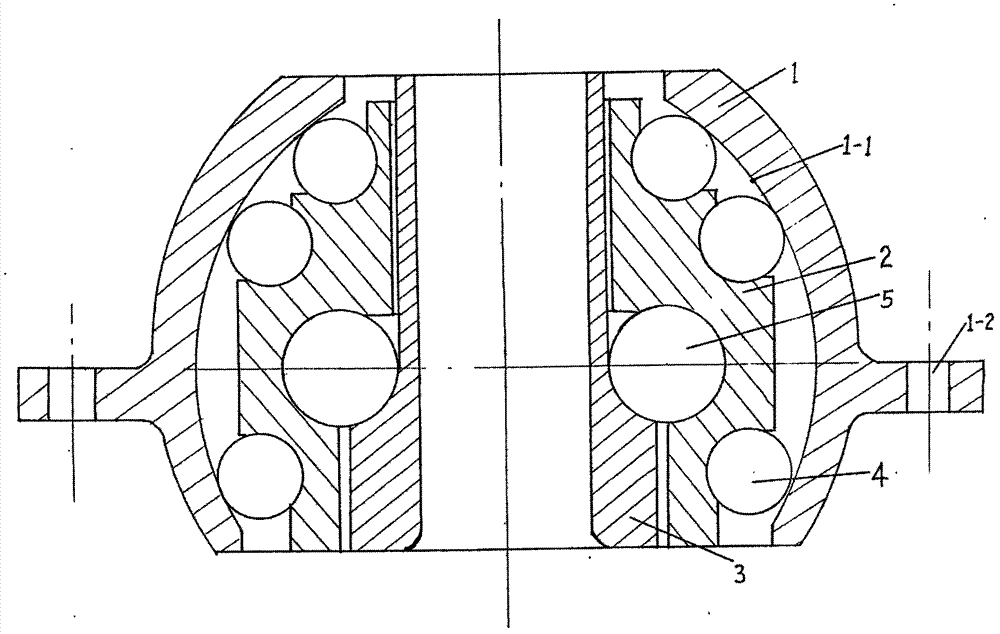

[0036] Such as Figure 10 A ball bladder multi-ring bearing with a diameter-reducing intermediate layer ferrule is shown, which consists of a bladder type outer ring 1, a diameter-reducing intermediate layer ferrule 2, two inner ferrules 3, inner rolling elements 5 and The outer rolling body is composed of 4. There are track grooves on the outer circumference of the two inner rings. There are shaft installation holes at the upper and lower ends of the axis line of the bladder type outer ring. There are 3 rows of outer rolling bodies and 4 rows of inner rolling bodies. Row, the inner track of the bladder type outer ring is a circular bladder inner track, and the diameter of the axial load-bearing end of the bladder inner track is small to ensure that the axial contact angle between the inner track and the rolling body is 30 degrees.

[0037]Among them, the axial section of the main body of the variable-diameter intermediate layer ferrule has a variable-diameter structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com