Biodegradable poly (butylene adipate terephthalate) micro-pore foaming particle with high foamability and preparation method thereof

A technology of terephthalic acid and polyadipic acid, applied in the direction of coating, etc., can solve the problems of not preparing high expansion ratio PBAT microcellular foaming materials, increasing production costs, overheating of foamed samples, etc., and achieves easy operation, The production cycle is short and the effect of promoting application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

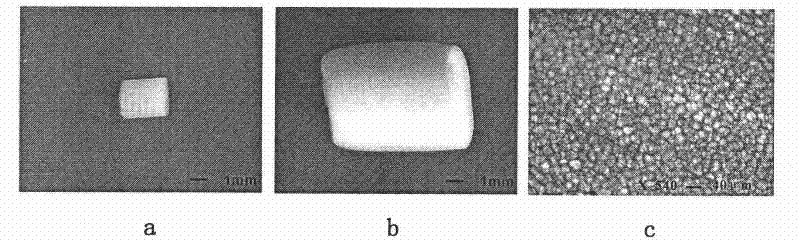

[0038] The particles of the unextended PBAT polymer and the particles of the extended PBAT polymer are placed in a high-pressure mold in a molding physical gas foaming device to ensure that the total volume of the particles does not exceed 1 / 30 of the mold volume, so that the particles have sufficient space for foaming. When the mold reaches the set temperature of 115°C, fill it with 16MPa CO 2 , kept at constant temperature and pressure for 15 minutes, and then released to normal pressure at a speed of 23MPa / s. The foamed particles were taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 1.

[0039] Table 1 Comparison of structure and properties of unextended and extended chain PBAT foamed particles

[0040]

Embodiment 2

[0042] The particles of the chain-extended PBAT polymer are placed in a high-pressure mold in a molding physical gas foaming device to ensure that the total volume of the particles does not exceed 1 / 30 of the mold volume, so that the particles have enough space for foaming. When the mold reaches the set temperature, fill it with 12MPa CO 2 , kept at constant temperature and pressure for 15 minutes, and then released to normal pressure at a speed of 17MPa / s. The foamed particles were taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 2.

[0043] Table 2 Comparison of structure and performance of PBAT expanded particles prepared by different foaming temperatures

[0044]

Embodiment 3

[0046] The particles of the chain-extended PBAT polymer are placed in a high-pressure mold in a molding physical gas foaming device to ensure that the total volume of the particles does not exceed 1 / 30 of the mold volume, so that the particles have enough space for foaming. When the mold reaches the set 115°C, fill in a certain pressure of CO 2 (The pressure is listed in Table 3 as the foaming pressure), held at a constant temperature for 15 minutes, and then released to normal pressure at a certain pressure relief speed (the pressure relief speed is listed in Table 3). The foamed particles were taken out and subjected to optical microscope analysis and density measurement, the results are shown in Table 3.

[0047] Table 3 Comparison of structure and performance of PBAT expanded particles prepared by different foaming pressures

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com