Waterproof anticorrosion breathable bolt for packaged bottle cap and manufacturing method of waterproof anticorrosion breathable bolt

A technology for packaging bottle caps and production methods, which is applied in the field of venting plugs, can solve problems such as corrosion resistance to acid and alkali solutions, safety hazards in production and transportation, and bottle caps that cannot be opened, so as to improve the ability to resist strong acids and alkalis, improve Antioxidant ability, convenience solution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

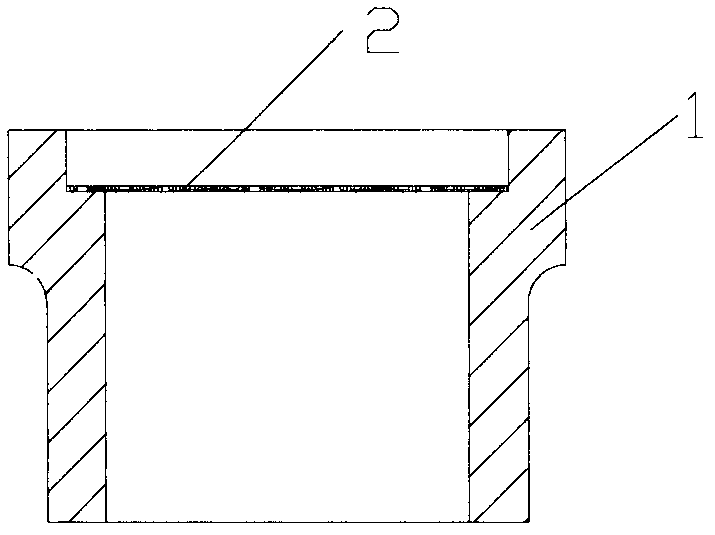

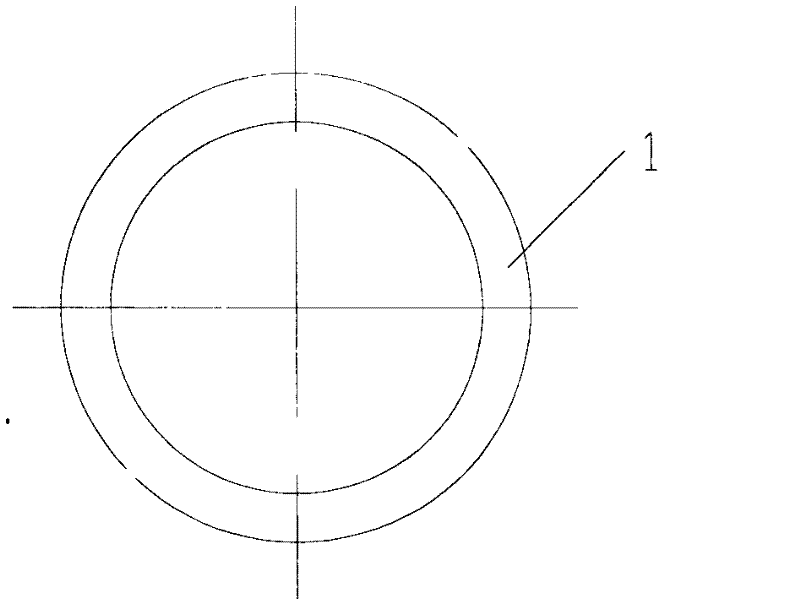

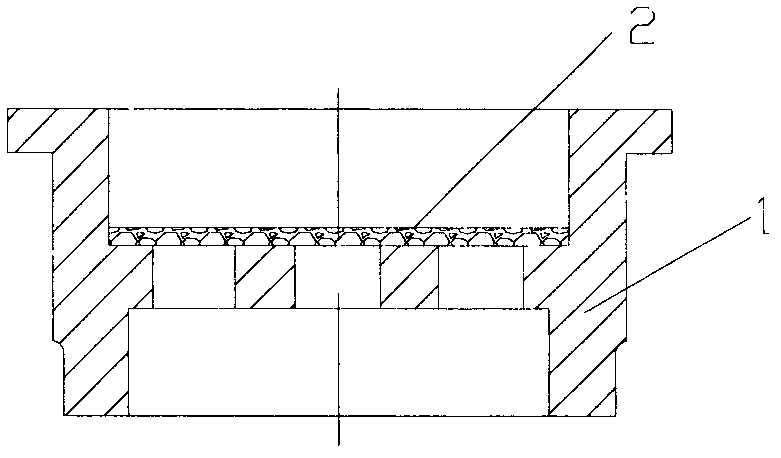

[0034] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0035] like Figure 1-10 As shown, a waterproof, anti-corrosion, and ventilating plug for a packaging bottle cap includes an injection molded part plug body 1, a breathable film patch 2 connected to the injection molded part plug body 1, and the outer diameter of the injection molded part plug body 1 is the same as that of the packaging bottle cap. The reserved inner holes are connected by interference fit, and the air-permeable film patch 2 is provided on the channel of the internal and external gas convection of the container equipped with the packaging bottle cap.

[0036] The invention designs the waterproof, anti-corro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com