Cutting torch for flame cleaning gun

A technology of flame cleaning and cutting nozzles, which is applied in the direction of gas flame welding equipment, combustion methods, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below through specific examples.

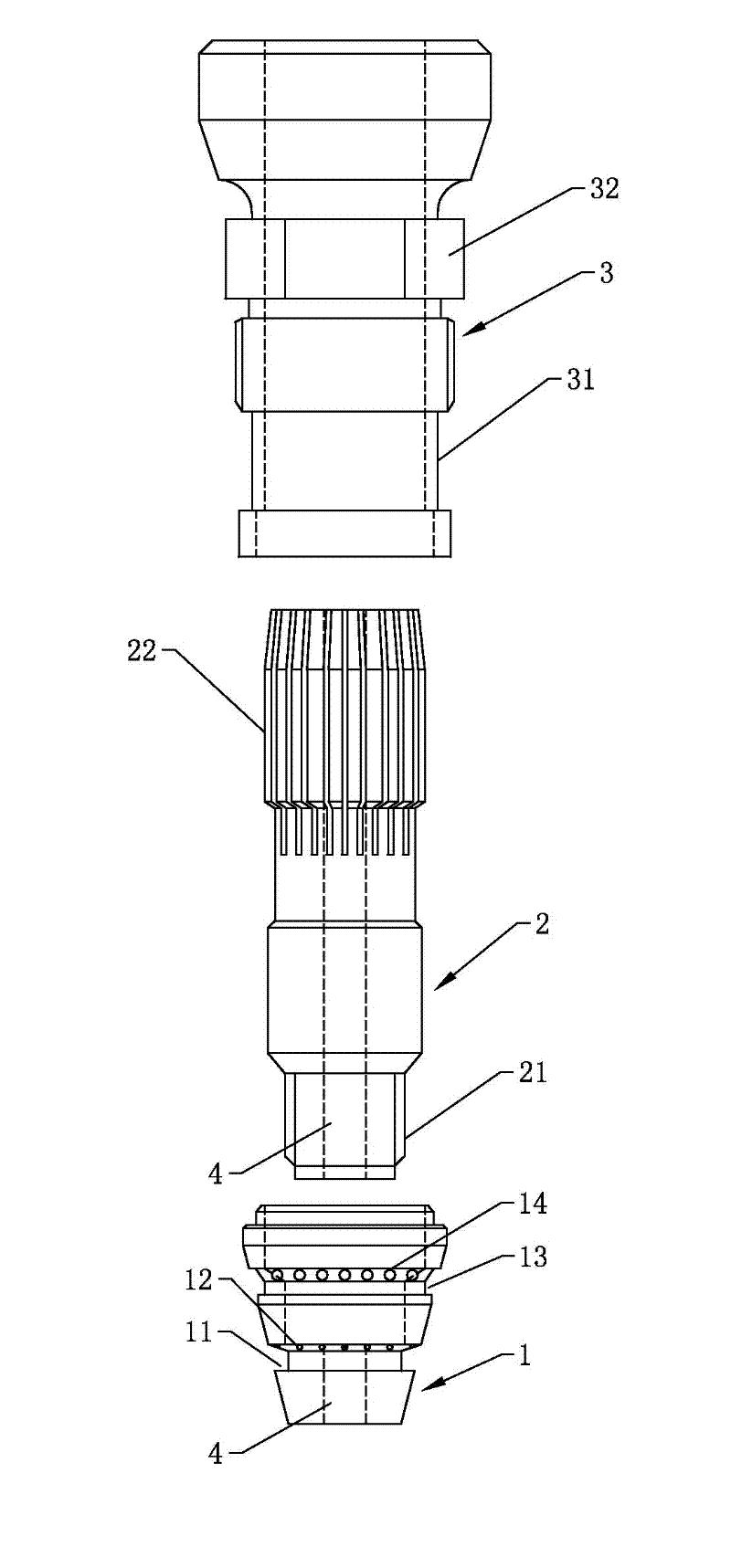

[0016] A flame cleaning gun cutting nozzle, such as figure 1 As shown, it includes a connecting part 1 for being installed on the connecting elbow of the flame cleaning gun. The head of the flame cleaning gun is provided with a connecting elbow, and the connecting part 1 is installed in the inside of the connecting elbow. The connecting part 1 Set in the shape of a truncated cone, the connecting part 1 is axially provided with an oxygen channel 4, and the connecting part 1 is provided with a gas ring groove 11 for communicating with the combustible gas pipeline of the flame cleaning gun, and for connecting with the flame cleaning gun. The mixed gas annular groove 13 communicated with the mixed gas pipeline of combustible gas and oxygen, what the gas of the present invention adopts is acetylene. The sealing connection between the frustum of the conical surface of the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com