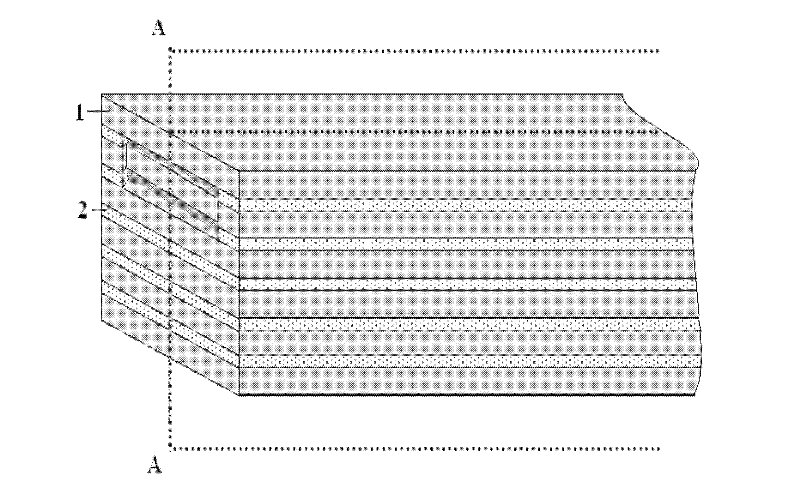

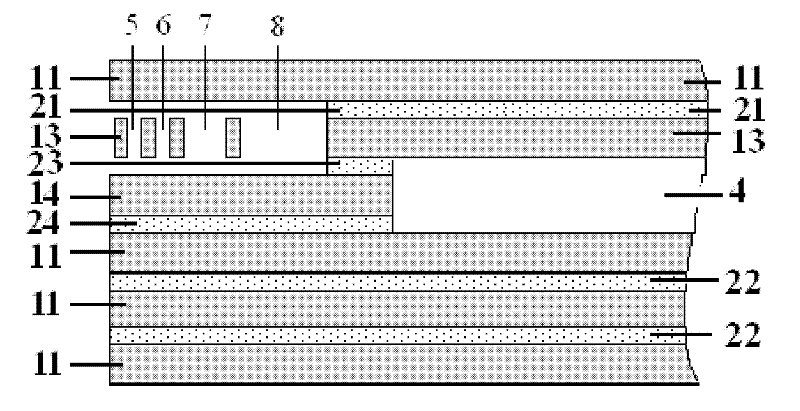

Multi-layer zirconia solid electrolyte composite chip and preparation method thereof

A technology for stabilizing zirconia and zirconia oxygen ions. It is applied in the direction of material analysis, instruments, and analysis materials through electromagnetic means. It can solve problems such as current leakage and achieve a compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

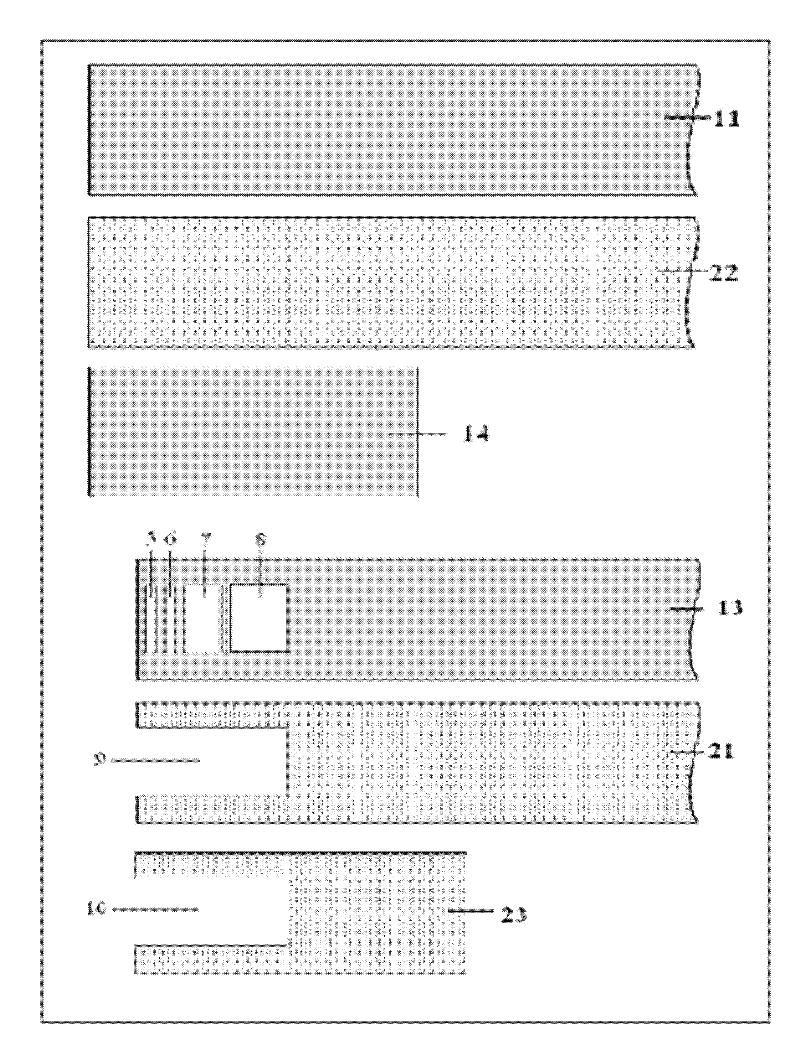

Embodiment 1

[0036] (1) Preparation of stabilized zirconia oxygen ion-conducting membrane: by 20g (Y 2 o 3 ) 0.08 (Sc 2 o 3 ) 0.01 (ZrO 2 ) 0.91 Mix with 0.6ml terpineol, 0.6g polyvinyl butyral, 0.8ml diethyl phthalate, 0.5ml polyethylene glycol 400, and 7ml ethanol ball mill to form a slurry and cast it. Thickness 200μm. (2) Preparation of stabilized zirconia bonded separator: 20g (Al 2 o 3 ) 0.03 (ZrO 2 ) 0.97 1. Glass powder mixed with 0.6ml terpineol, 0.8g diethyl phthalate, 0.6ml polyethylene glycol 400, 0.8g acrylamide ethyl acrylate, 7ml ethanol ball milling to form a slurry and then casting; Thickness 40μm. (3) 5 layers of the above-mentioned stabilized zirconia oxide ion-conducting membrane and 7 layers of stabilized zirconia bonded isolation membrane were aged at 50°C for 3 hours; the aged membrane was punched, printed, and dotted according to the size required by the sensor. After through-holes, the two membranes are stacked alternately and at 75°C at 200Kgf / cm 2 ...

Embodiment 2

[0039] (1) Preparation of stabilized zirconia oxygen ion-conducting membrane: by 20g (Y 2 o 3 ) 0.02 (Sc 2 o 3 ) 0.11 (ZrO 2 ) 0.87 Mix with 0.6ml terpineol, 0.5ml polyethylene glycol 400, 0.8ml diethyl phthalate, 0.6g polyvinyl butyral, and 12ml ethanol ball mill to form a slurry and cast it. Thickness 250μm.

[0040] (2) Preparation of stabilized zirconia bonded separator: 18g (Y 2 o 3 ) 0.03 (ZrO 2 ) 0.97 , 2g glass powder and 0.6ml terpineol, 0.5ml polyethylene glycol 400, 0.8g diethyl phthalate, 0.8g acrylamide ethyl acrylate, 10ml ethanol ball mill and mix to form slurry in (1) The prepared stabilized zirconia oxygen ion conducting membrane is printed on it; the thickness is 30 μm.

[0041] (3) The above-mentioned 6 layers of stabilized zirconia oxygen ion-conducting membrane and 8 layers of stabilized zirconia bonded isolation membrane were aged at 60°C for 3 hours; the aged membrane was punched, printed, and dotted according to the size required by the sen...

Embodiment 3

[0043] (1) Preparation of stabilized zirconia oxygen ion-conducting membrane: by 20g (Y 2 o 3 ) 0.08 (ZrO 2 ) 0.92 Mix with 0.6ml terpineol, 0.5ml polyethylene glycol 400, 0.8ml diethyl phthalate, 0.6g polyvinyl butyral, and 11ml ethanol ball mill to form a slurry and cast it. Thickness 150μm.

[0044] (2) Preparation of stabilized zirconia bonded separator: 15g (Y 2 o 3 ) 0.02 (Al 2 o 3 ) 0.01 (ZrO 2 ) 0.97, 5g glass powder and 0.6ml terpineol, 0.5ml polyethylene glycol 400, 0.8g diethyl phthalate, 0.8g acrylamide ethyl acrylate, 10ml ethanol ball milling to form a slurry and then casting into; thickness 50μm.

[0045] (3) The above-mentioned 8 layers of stabilized zirconia oxygen ion-conducting membrane and 10 layers of stabilized zirconia bonded isolation membrane were aged at 50°C for 3 hours; the aged membrane was punched, printed, and dotted according to the size required by the sensor. After the through hole, the two membranes are stacked alternately and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com