Method for detecting ash content of tobacco

A technology of ash content and detection method, which is applied in the direction of removing a certain component and weighing, etc., can solve the problems of operator safety, no automatic emptying system, cumbersome operation steps, etc., and achieves low cost, simple method, and analysis. Data-accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

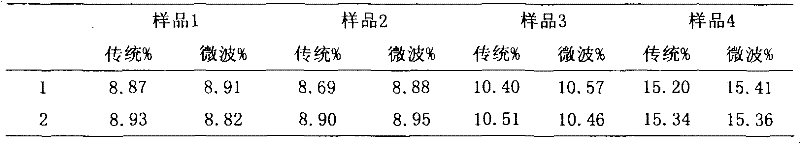

Examples

Embodiment Construction

[0017] The equipment used in this method is purchased from the market. The specific operation steps of the method are as follows:

[0018] 1. Ashing of tobacco samples

[0019] After crushing the tobacco sample and passing through a 30-mesh sieve, accurately weigh 1g (accurate to 0.0002g) of the sample and place it in a quartz fiber crucible, burn it in a microwave muffle furnace at 500°C for 20min, take it out and cool it in a desiccator until Accurately weigh at room temperature.

[0020] 2. Calculate the ash content:

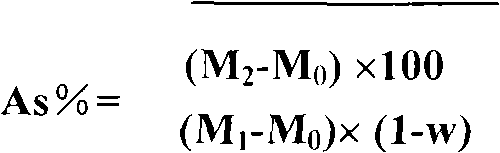

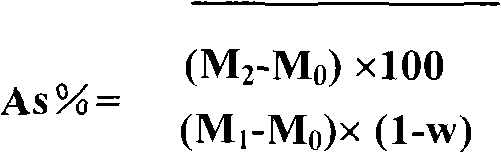

[0021] As % = ( M 2 - M 0 ) × 100 ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com