Multilayer coextrusion medical blister composite packaging film and preparation method thereof

A composite packaging film and multi-layer co-extrusion technology, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of poor compounding of materials, great physical injury of operators, and reduction of physical and mechanical equipment. Performance and other issues, to achieve the effect of maintaining physical and mechanical properties, improving compatibility, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

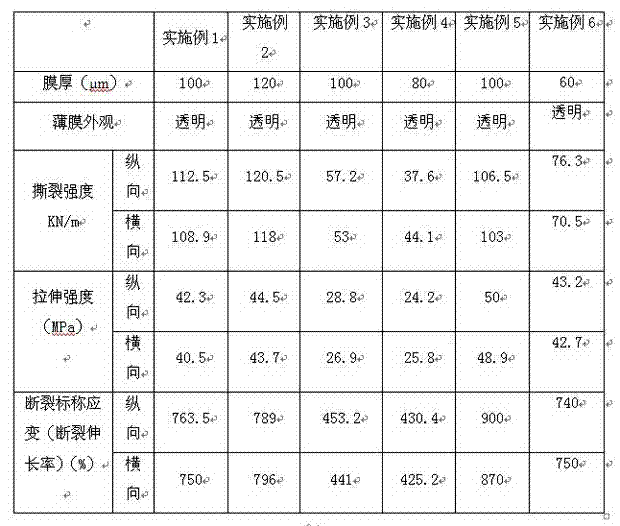

Examples

preparation example Construction

[0047] In the present invention, the preparation method of the multi-layer co-extruded medical blister composite packaging film comprises the following steps:

[0048]1) Extrusion: The raw materials of each layer are sent to three or five extruders of a three-layer or five-layer co-extrusion blown film unit to be heated and melted into a polymer melt, and then passed through each flow channel of the spiral center die. The layer components are laminated on the upper part of the die to form a co-extruded film; the three-layer or five-layer co-extrusion blown film units all use a single-screw extruder with a screw length-diameter ratio of 32:1. The body temperature of the machine is 160~240℃, the die temperature is 190~240℃, and the screw speed is 15~50 rpm;

[0049] 2) Blown film: When the polymer melt flows out of the die, it is made by one-time inflation of a three-layer or five-layer co-extrusion blowing film unit, and then stretched into a film, and the inflation ratio is 1:...

Embodiment 1

[0058] Three-layer co-extrusion machine to produce 0.10mm thick co-extruded film:

[0059] 1) Extrusion: the outer layer raw material mixes low density polyethylene with linear polyethylene (by mass ratio 1:1); the middle layer raw material mixes linear low density polyethylene with linear polyethylene metallocene polyethylene (by mass ratio 2 : 1 mixed); the inner layer raw material is polypropylene. The three raw materials are extruded into the extruder, heated, plasticized, melted and extruded, and then entered into the three-layer die head in the center of the spiral. Three-layer raw material temperature range: the body temperature of the outer extruder is 160℃~200℃, the body temperature of the middle layer extruder is 170℃~200℃, the body temperature of the inner layer extruder is 180℃~210℃, and the temperature of the die head It is 190℃~210℃. The screw speed is: 30 rpm for the outer layer, 40 rpm for the middle layer, and 45 rpm for the inner layer.

[0060] 2) Blown f...

Embodiment 2

[0064] Three-layer co-extrusion machine to produce 0.12mm thick co-extruded film:

[0065] 1) Extrusion: The outer layer raw material is mixed with low density polyethylene and linear polyethylene (mixed by mass ratio 8:1); the middle layer raw material is mixed with linear low density polyethylene and linear polyethylene metallocene polyethylene (by mass ratio of 10 : 1 mixed); the inner layer raw material is polypropylene. The three raw materials are extruded into the extruder, heated, plasticized, melted and extruded, and then entered into the three-layer die head in the center of the spiral. Three-layer raw material temperature range: the temperature of the outer extruder body is 170℃~200℃, the temperature of the middle layer extruder body is 180℃~200℃, the temperature of the inner layer extruder body is 180℃~210℃, and the temperature of the die head It is 200℃~210℃. The screw speed is: 35 rpm for the outer layer, 50 rpm for the middle layer, and 40 rpm for the inner lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com