Method and device for repairing copper pipe component on heat exchanger of air conditioner

A heat exchanger and copper tube technology, which is applied in the field of air conditioner manufacturing, can solve the problems that copper tubes cannot be replaced, enterprise losses, and heat exchanger copper tubes are easily damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

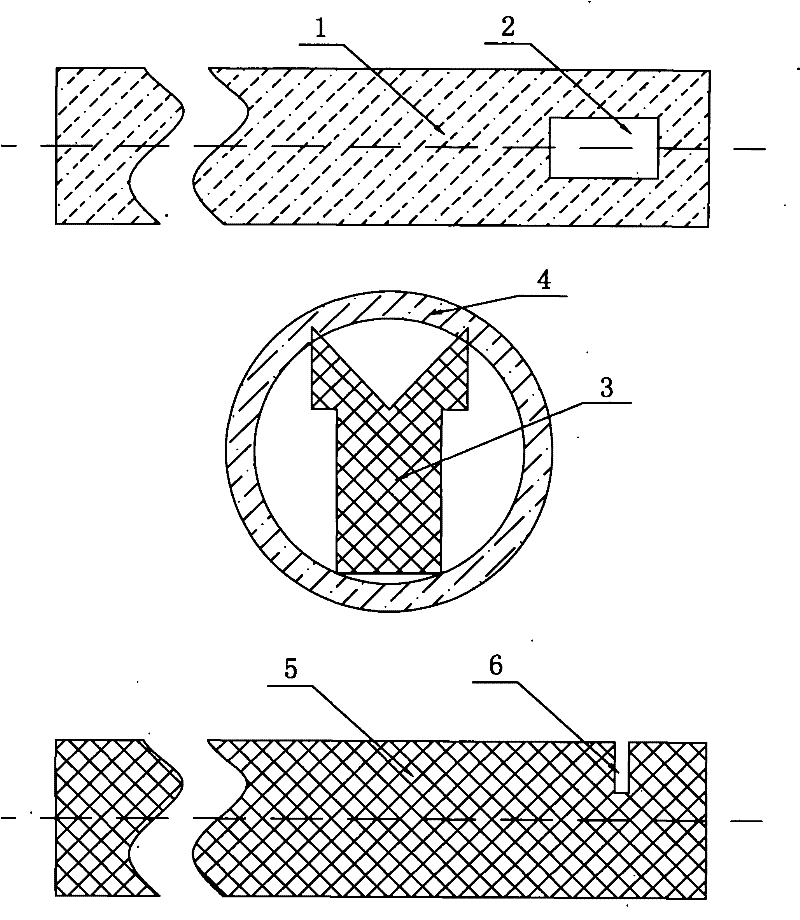

[0008] Refer to the attached figure 1 The method and device for repairing the copper tube assembly of the air conditioner heat exchanger according to the present invention will be described in detail below.

[0009] The method and device for repairing the copper tube assembly of the air conditioner heat exchanger of the present invention provide the following tools or equipment: including high-pressure air, air shovel, air pipe, scissors, needle-nose pliers, cutter head 3, cutter bar 1, and slot 6 Pumping pipe core rod 5, described repair method comprises the steps:

[0010] a. The trachea is connected to the air shovel, connected to high-pressure air, and scissors, needle-nose pliers, cutter head 3 and cutter bar 1 are prepared.

[0011] b. Use scissors to cut off the U-shaped tube end of the copper tube of the heat exchanger that needs to be repaired, and then use an air gun to hold the cutter bar 1 and the cutter head 3 that are slightly smaller than the inner hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com