Indirectly heated fluidized bed dryer

A fluidized bed drying, indirect technology, used in indirect heat exchangers, fluidized bed heat exchangers, heating to dry solid materials, etc., can solve the problems of fluid mechanics interference, the dryer shell is not kept constant, etc. Reduce dust discharge, avoid fluidized bed coarsening, and improve heat transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

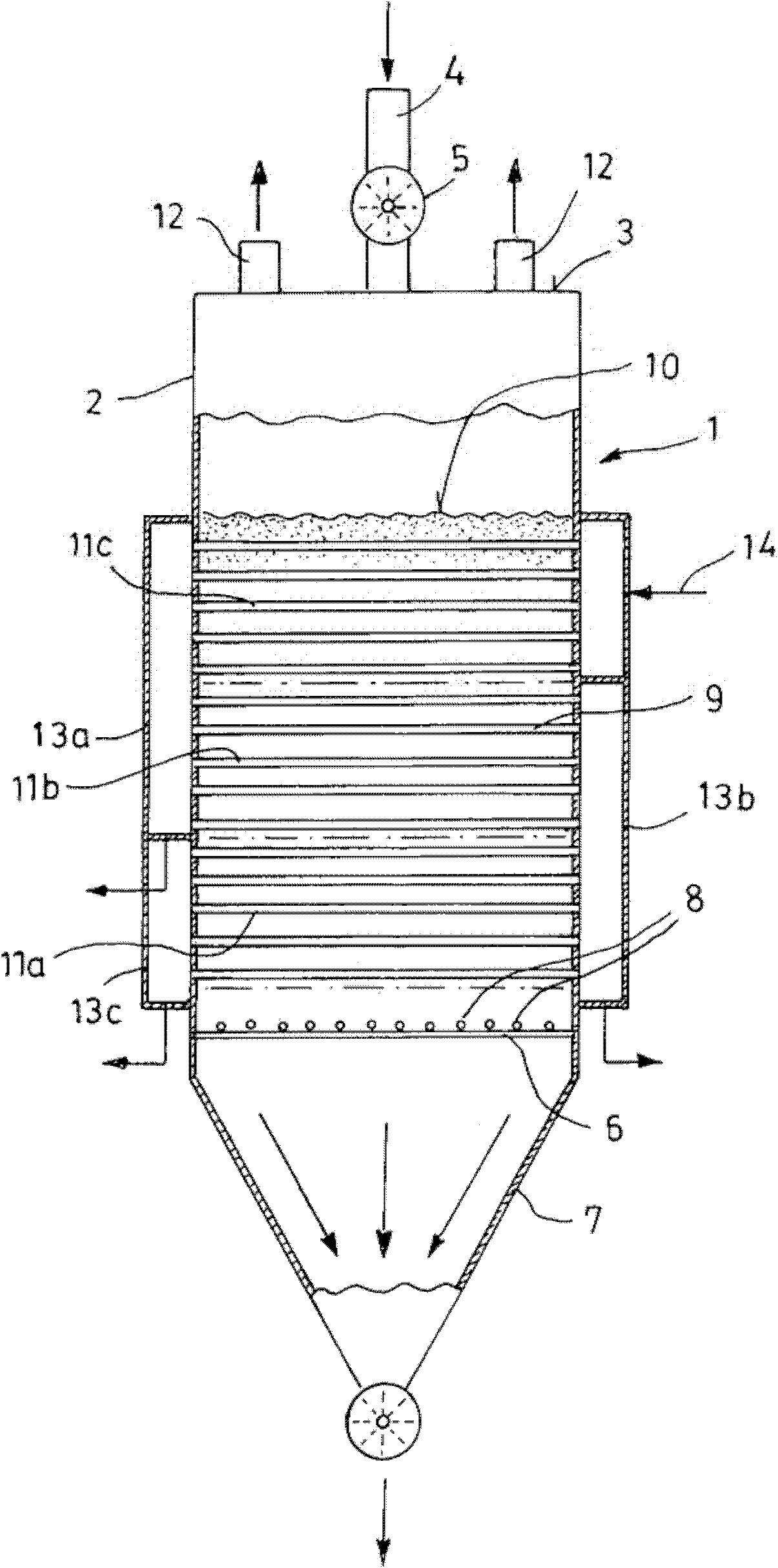

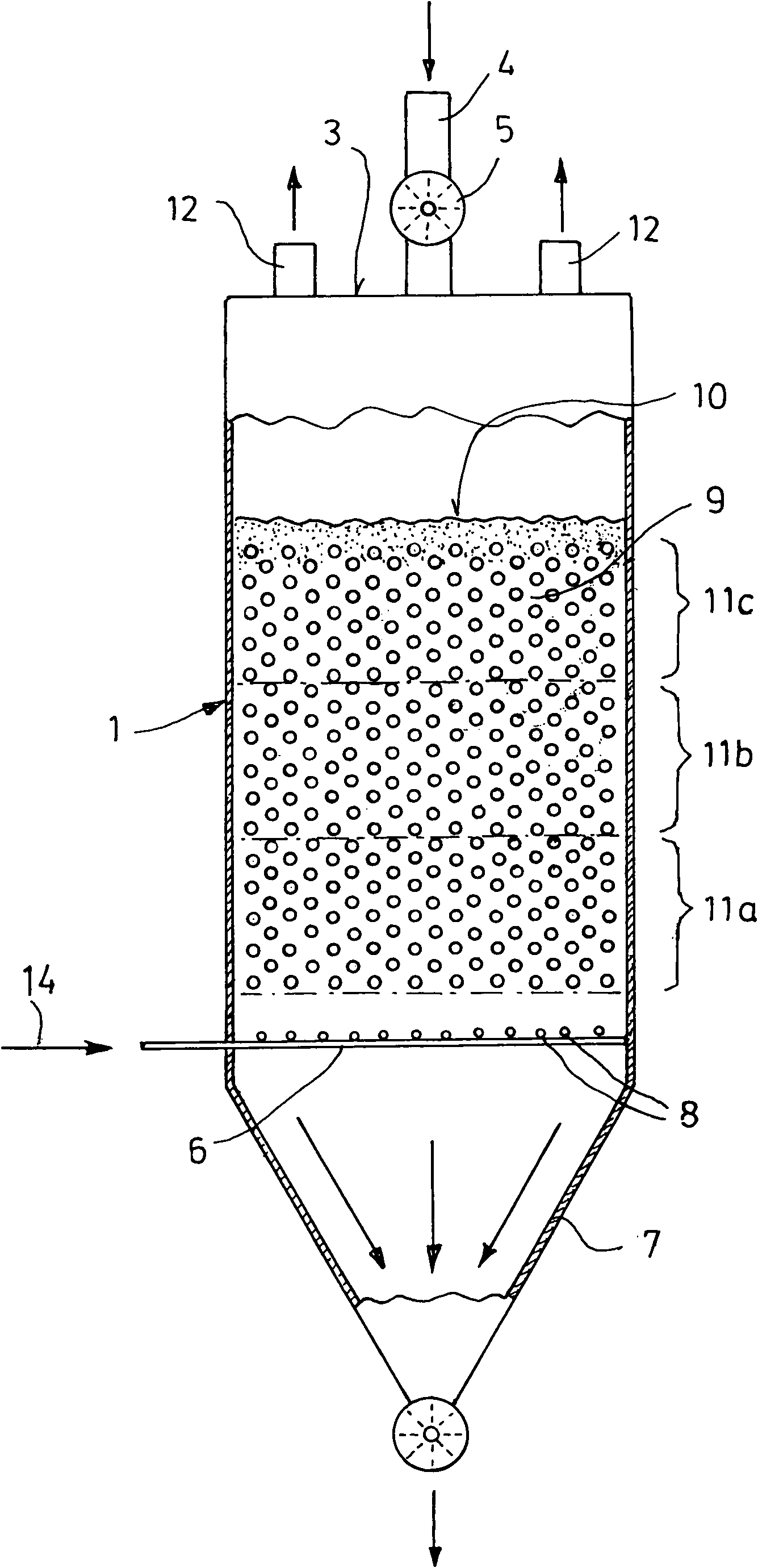

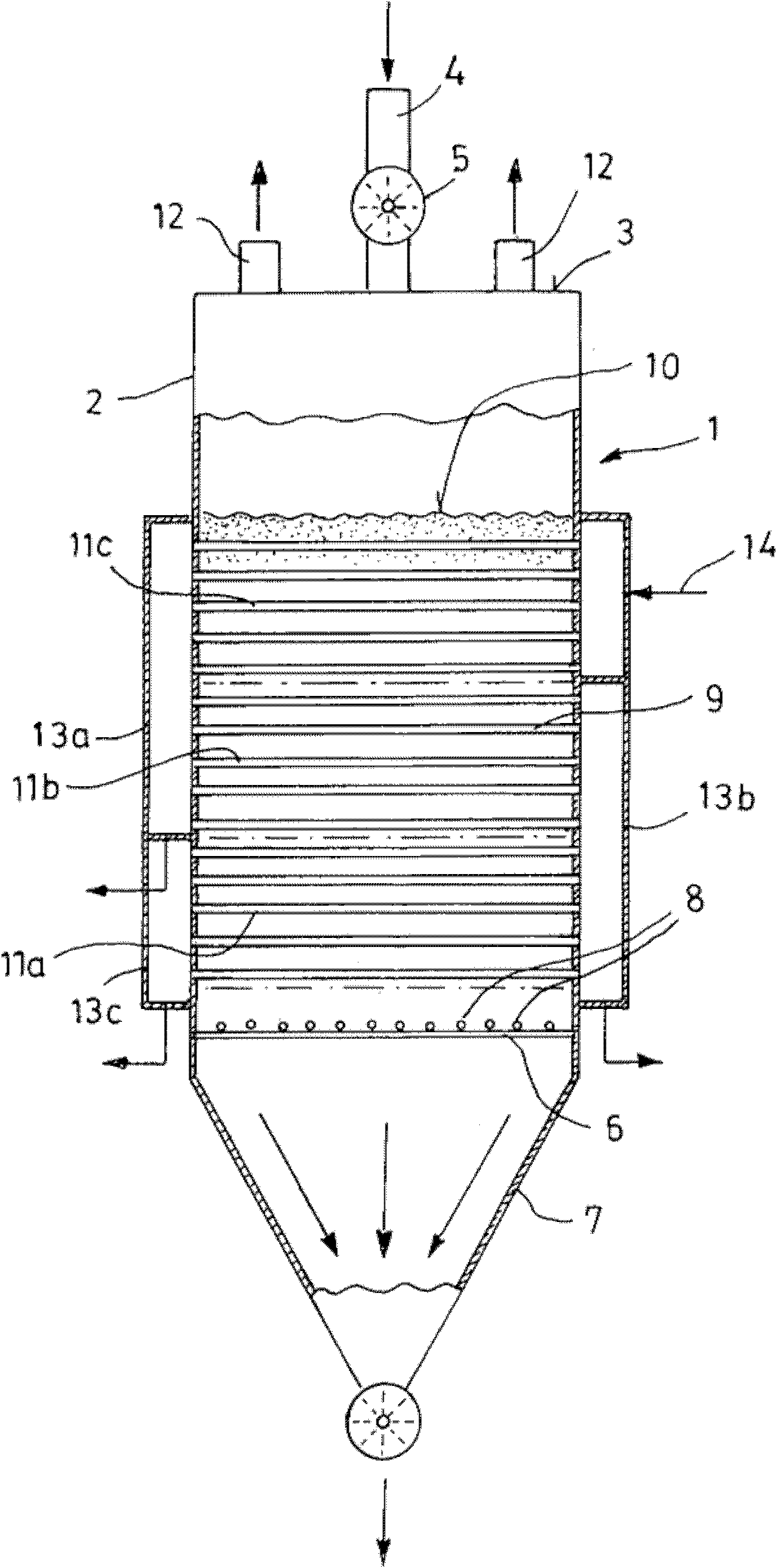

[0027] figure 1 The fluidized bed dryer (1) shown has a housing (2) with a rectangular cross-section. A filling pipe (4) with a honeycomb wheel gate (5) is arranged on the upper end surface (3) of the fluidized bed dryer (1) as a raw lignite feeding device. On the lower end of the fluidized bed dryer (1) away from the upper end surface (3), a funnel-shaped outlet end (7) is provided below the aeration bottom (6), and a honeycomb wheel gate is arranged on the lower end of the outlet end. (5) Form mechanical discharge device. There, too, a screw conveyor or the like can be used as a mechanical discharge device instead of the honeycomb wheel gate. In this embodiment, the fluidized bed dryer ( 1 ) is mainly used for drying lignite and is described with reference to a method for drying lignite. However, the invention should be understood that the dryer can also be used for drying other particulate matter.

[0028] The gas filling bottom (6) is provided with a nozzle (8) for fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com