Method for separating palladium and copper from solution containing copper, cobalt and nickel by taking acylthiourea as extractant

A technology for acylthiourea and copper-cobalt-nickel-palladium, which is applied in the field of extraction and separation of palladium and copper, can solve the problems of difficult separation of noble and base metals, long processing time, complicated precipitation process, etc. The effect of short equilibration time and high enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

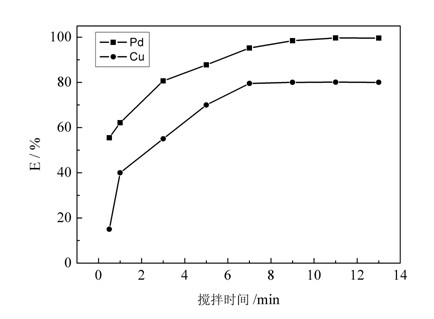

[0045] Get the mixed material liquid (Pd) of the copper-cobalt-nickel-palladium of 10ml 2+ The concentration is 100mg / L, Cu 2+ The concentration is 100mg / L) in the extraction tank to adjust the acidity of the system to pH=1.5; add 1g of SUL-1 and paraffin solid (SUL-1 concentration 0.0083 mol / L) to maintain the system at A:O=4 : 1, in a water bath at 55°C, extract 2 times, each 10min (SUL-paraffin to Pd 2+ The extraction rate is stable and close to 99%); cooling, standing still, after the phase separation is completed, the organic phase loaded with palladium is mixed with a mixed aqueous solution of thiourea and hydrochloric acid (wherein the mass percentage of thiourea is 0.5%, and the concentration of hydrochloric acid is 0.5 mol · L -1 ) for back-extraction, control the back-extraction ratio to A:O=4:1, back-extract three times at 55°C, 10min each time; cool and separate the phases, and recycle the organic phase after back-extraction and elution for normal extraction. Th...

Embodiment 2

[0049] Get the mixed material liquid (Pd) of the copper-cobalt-nickel-palladium of 10ml 2+ The concentration is 200mg / L, Cu 2+ The concentration is 200mg / L), put it in the extraction tank, and adjust the acidity of the system to pH=2.0; add 2g of SUL-1 and paraffin solid extractant (in which the concentration of SUL-1 is 0.009 mol / L), so that the system is maintained at A :O=3:1, in a water bath at 60°C, the number of forward extraction stages is 2 times, each 10min; cooling, standing still, after the phase separation is completed, the organic phase loaded with palladium is mixed with a mixed aqueous solution of thiourea and hydrochloric acid (the mass percent of thiourea is 0.5%, the concentration of hydrochloric acid is 0.5 mol L -1 ) for back-extraction, the back-extraction ratio is A:O=3:1, back-extraction 3 times at 60°C, 10min each time; cooling and phase separation, the organic phase eluted by back-extraction is recycled for normal extraction. The concentration of Pd ...

Embodiment 3

[0053] Get the mixed material liquid (Pd) of the copper-cobalt-nickel-palladium of 10ml 2+ The concentration is 100mg / L, Cu 2+ The concentration is 100mg / L), put it in the extraction tank, and adjust the acidity of the system to pH=1.5; add 1g of SUL-2 and paraffin solid extractant (the concentration of SUL-2 is 0.0083mol / L), so that the system is maintained at A :O=3.5:1, in a water bath at 65°C, the forward extraction series is 2 times, each time 10min (SUL-2 paraffin to Pd 2+ The extraction rate is stable and close to 99%); cooling, standing still, after the phase separation is completed, the organic phase loaded with palladium is mixed with a mixed aqueous solution of thiourea and hydrochloric acid (wherein the mass percentage of thiourea is 0.8%, and the concentration of hydrochloric acid is 1 mol · L -1 ) for back-extraction, the back-extraction ratio is A:O=3.5:1, back-extraction 3 times at 65°C, 10min each time; cooling and phase separation, the organic phase eluted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com