Method for brewing ultrahigh-gravity beer by ultrahigh-gravity Saccharomyces cerevisiae

A brewer's yeast, high-concentration technology, applied in beer fermentation methods, beer brewing, microorganism-based methods, etc., can solve problems such as poor cohesion, poor foam retention, and difficult flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Breeding of embodiment 1 ultra-high concentration yeast

[0019] 1. EMS mutation breeding

[0020] Add 30ul of EMS stock solution to 1ml sterile phosphate buffer solution (pH=7.0) of starting yeast (strain F preserved by China Academy of Food and Fermentation Industry) with high-concentration brewing performance (18°P), oscillate to disperse the cells, and place Incubate on a shaker at 30°C for 30 minutes; centrifuge, suspend cells in sterile water, wash twice with 5% Na2S2O3, resuspend cells in 1ml sterile water, dilute to 10 -3 , smeared on 2-deoxy-D-glucose plate and cultured for 7 days, the strain growing on the culture medium is the target strain.

[0021] 2. Alcohol resistance screening and acclimatization

[0022] Inject the above strains into wort containing different alcohol concentrations (6%-16%), check the fermentation conditions, and select strains that can tolerate high alcohol concentrations. Add 50ml of high-concentration wort (28°P) into the test tub...

Embodiment 2

[0028] The fermentation of embodiment 2 extra-high-strength beer

[0029] Fermentation using the above strains by the following fermentation steps:

[0030] 1) Saccharification, use 60-70% malt and 30-40% rice to make the original wort concentration of 18°P, add syrup in the boiling pot, adjust the wort concentration to 28°P;

[0031] 2) Fermentation, after the wort is cooled, the oxygenation amount is 10-12ppm, and the inoculum is inoculated, and the inoculation amount is controlled at 2.5*10 7 per ml, the fermentation temperature is 14°C, and the sugar content of the booster is controlled at 9°P;

[0032] 3) Dilution, the dilution ratio of the high-concentration dilution process is 100-120%.

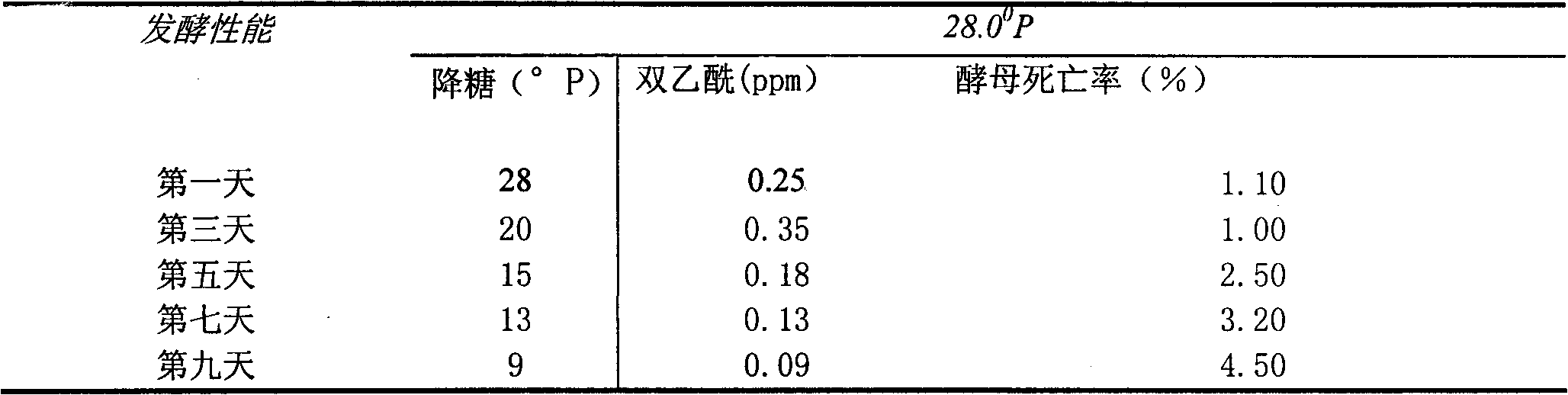

[0033] Fermentation performance index

[0034]

[0035] It can be seen that the ultra-high concentration fermentation can be carried out normally, and the mortality rate of the yeast has not increased greatly, which is lower than the regulation that the mortality rate of general ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com