Method for preparing firework composition by boiling granulation process

A technology of pyrotechnic agent and boiling granulation, which is applied in the direction of explosives, etc., can solve the problems of easy explosion hazard and low efficiency, and achieve the effects of stable discharge performance, uniform agent particles, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

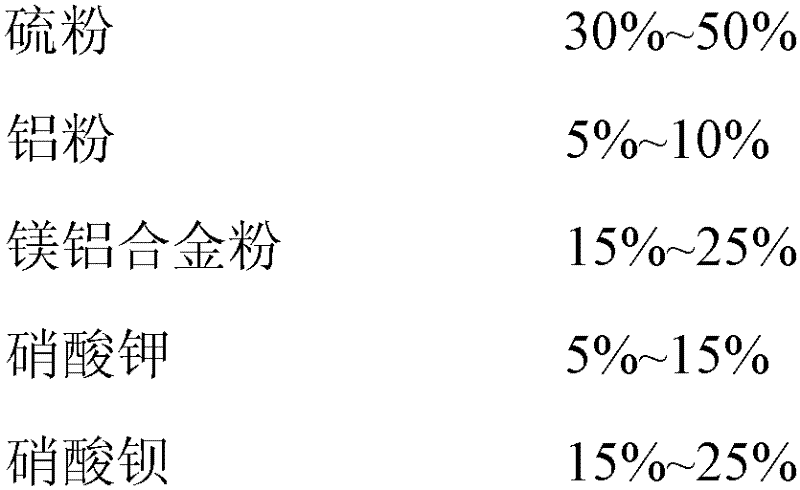

[0013] The formula of the pyrotechnic agent used is:

[0014]

[0015] (1) Weigh 3.32kg, 0.676kg, 1.576kg, 0.732kg and 1.688kg of fine powdered sulfur powder, aluminum powder, magnesium aluminum alloy powder, potassium nitrate and barium nitrate respectively, and use them in the boiling granulator Air flow at a velocity of 1 m / s was mixed for 5 min.

[0016] (2) 0.2kg fine powdery cooked glutinous rice flour is made into an aqueous solution with a mass fraction of 5%.

[0017] (3) Atomize the solution prepared in (2) at a rate of 100ml / min under a pressure of 0.3MPa and spray it into the boiling granulator in (1), while using a rate of 1m / s and a temperature of 50°C The airflow prepares the atomized solution and the fine powder medicine into granular medicine, and obtains the medicine product after drying.

[0018] The pyrotechnic agent prepared by the method has uniform particles, good fluidity and no dust. The discharge effect of the fireworks and firecrackers produced...

Embodiment 2

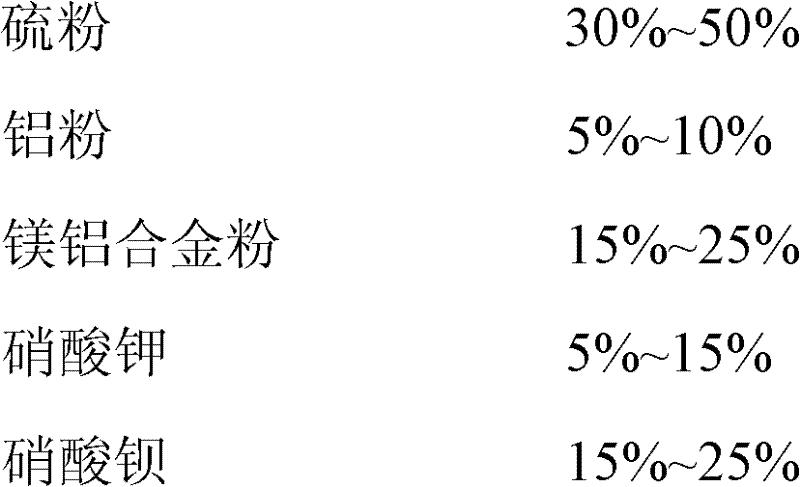

[0020] The formula of the pyrotechnic agent used is:

[0021]

[0022] (1) Weigh 3.32kg, 0.676kg, 1.576kg, 0.732kg and 1.688kg of fine powdered sulfur powder, aluminum powder, magnesium aluminum alloy powder, potassium nitrate and barium nitrate respectively, and use them in the boiling granulator Air flow at a velocity of 1.5 m / s was mixed for 5 min.

[0023] (2) 0.24kg fine powdery cooked glutinous rice flour is made into an aqueous solution with a mass fraction of 6%.

[0024] (3) Atomize the solution prepared in (2) at a rate of 150ml / min under a pressure of 0.4MPa and spray it into the boiling granulator in (1), while using a rate of 1.5m / s and a temperature of 60°C The airflow prepares the atomized solution and the fine powder medicine into granular medicine, and obtains the medicine product after drying.

[0025] The pyrotechnic agent prepared by the method has uniform particles, good fluidity and no dust. The discharge effect of the fireworks and firecrackers pro...

Embodiment 3

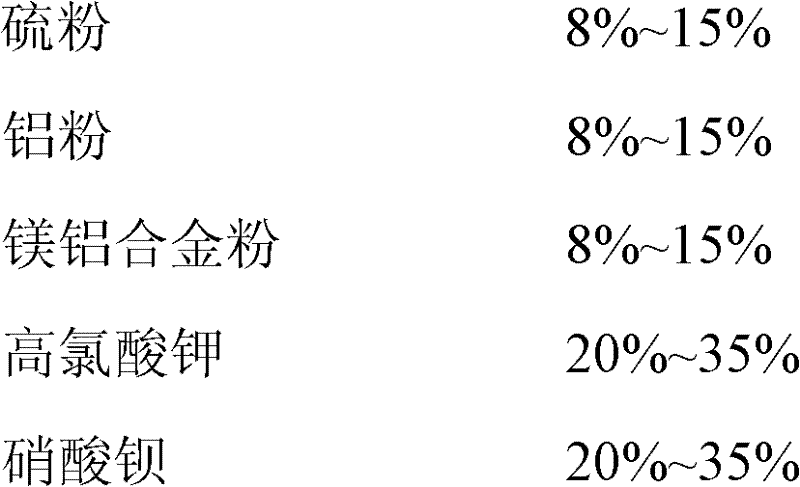

[0027] The formula of the pyrotechnic agent used is:

[0028]

[0029] (1) Weigh 1kg, 1kg, 1kg, 2.5kg and 2.5kg of fine powdered sulfur powder, aluminum powder, magnesium-aluminum alloy powder, potassium perchlorate and barium nitrate respectively, and use a speed of 1.5 in the boiling granulator The m / s airflow was mixed for 5 minutes.

[0030] (2) 0.15kg of fine powdery cooked glutinous rice flour is made into an aqueous solution with a mass fraction of 4%.

[0031] (3) Atomize the solution prepared in (2) at a rate of 150ml / min under a pressure of 0.3MPa and spray it into the boiling granulator in (1), while using a speed of 2m / s and a temperature of 60°C The airflow prepares the atomized solution and the fine powder medicine into granular medicine, and obtains the medicine product after drying.

[0032] The pyrotechnic agent prepared by the process has uniform particles, good fluidity and no dust. When the fireworks and firecrackers produced by the prepared granule a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com