Mesoporous antireflective film and transparent conducting film composite coated glass and coating method thereof

A technology of transparent conductive film and composite coating, which is applied in the field of building materials, can solve the problems of blocking infrared radiation, such as doping, and high surface resistance of the film layer, and achieve good effects of blocking infrared radiation, small surface resistance, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

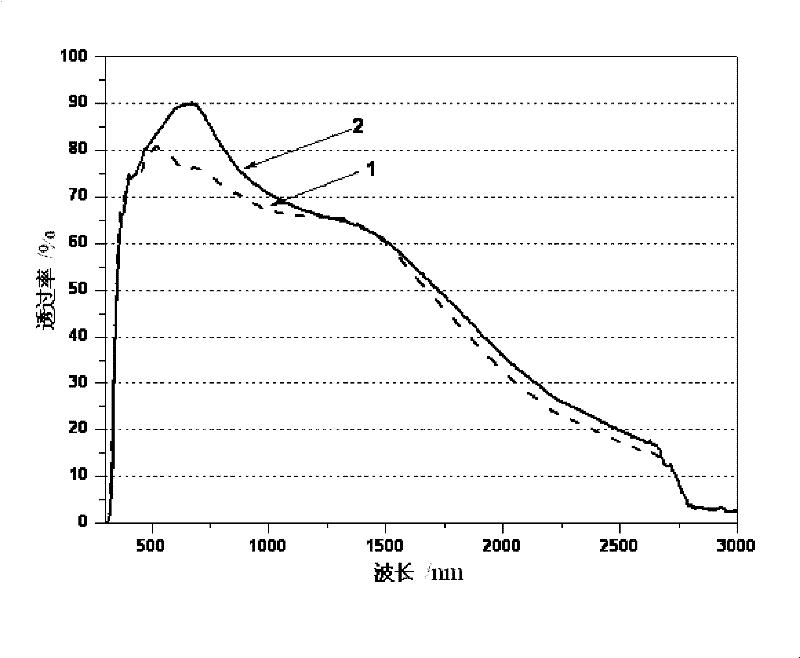

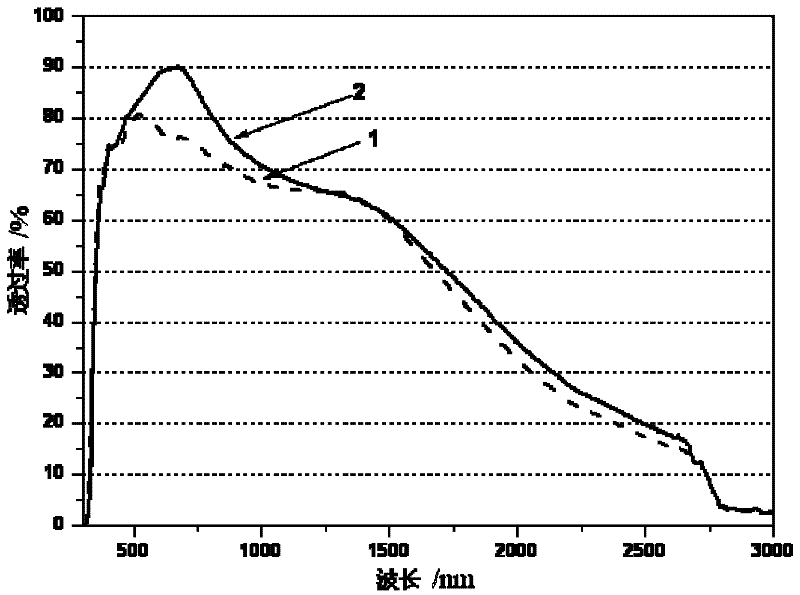

[0013] The specific scheme of the mesoporous anti-reflection film and transparent conductive film composite coated glass of the present invention is as follows. A transparent conductive film is coated on one side or both sides of the glass substrate, and an anti-reflection film is coated on the transparent conductive film. The transparent conductive film is a doped wide-bandgap semiconductor film, and the anti-reflection film is mesoporous SiO 2 membrane.

[0014] The doped wide bandgap semiconductor film is made of ZnO, SnO 2 、In 2 o 3 A film formed by doping one or more of Al, Ag, Ga, B, In, F, Sn, Zr, Ce, Sc in one of them, such as ZnO:Al. The film thickness of the doped wide bandgap semiconductor film is 10-600 nm, preferably 120-150 nm.

[0015] The mesoporous SiO 2 The film thickness of the film is 10 to 250 nm, preferably 80 to 110 nm.

[0016] The specific scheme of the glass coating method of the mesoporous anti-reflection film and transparent conductive film co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com