Low surface energy polyester film and preparation method and application thereof

A low surface energy, polyester film technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. Composite and other issues to achieve the effect of meeting food hygiene requirements, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

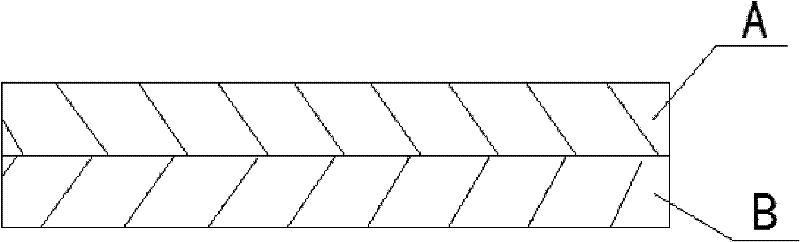

[0059] figure 1 It is a schematic cross-sectional view of Embodiment 1 of the present invention.

[0060] Such as figure 1 It can be seen that the low surface energy polyester film obtained in this example has a two-layer structure, one of which is a modified polyester layer, and the other layer is a low surface energy polyester layer.

[0061] First, the raw materials are mixed separately to make modified polyester bright slices, inorganic additive slices and low surface energy additive slices, and they are dried on a fluidized bed at a drying temperature of 150°C for 4 hours.

[0062] The modified polyester bright slices include: isophthalic acid modified polyethylene terephthalate (the molar content ratio of isophthalic acid is 10%); the modified polyester bright slices are tested Its melting point is between 210°C and 240°C, and its glass transition temperature is between 60°C and 80°C.

[0063] Inorganic additive chips include: SiO 2 The mass fraction of the powder is...

Embodiment 2

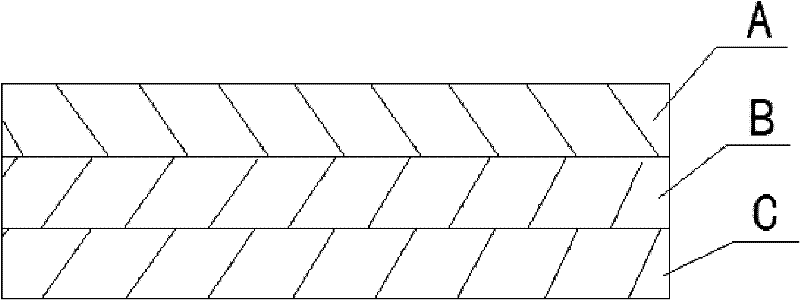

[0072] figure 2 It is a schematic cross-sectional view of Embodiment 2 of the present invention.

[0073] Such as figure 2 It can be seen that the low surface energy polyester film in this embodiment has a three-layer structure, wherein two layers are modified polyester layers, and the other layer is a low surface energy polyester layer.

[0074] First, the raw materials are mixed separately to make modified polyester bright slices, inorganic additive slices and low surface energy additive slices, and they are dried on a fluidized bed at a drying temperature of 150°C for 4 hours.

[0075] The modified polyester bright slices include: isophthalic acid modified polyethylene terephthalate (the molar content ratio of isophthalic acid is 13%); the modified polyester bright slices are tested Its melting point is between 210°C and 240°C.

[0076] Inorganic additive chips include: SiO 2 The mass fraction of the powder is 2000ppm, and the rest is isophthalic acid-modified polyeth...

Embodiment 3

[0084] The low surface energy polyester film of this embodiment has a three-layer structure, wherein two layers are modified polyester layers, and the other layer is a low surface energy polyester layer.

[0085] First, the raw materials are mixed separately to make modified polyester bright slices, inorganic additive slices and low surface energy additive slices, and they are dried on a fluidized bed at a drying temperature of 120°C for 4 hours.

[0086] The modified polyester bright slices include: isophthalic acid modified polyethylene terephthalate (the molar content ratio of isophthalic acid is 16%); the modified polyester bright slices are tested Its melting point is between 200°C and 240°C, and its glass transition temperature is between 60°C and 80°C.

[0087] Inorganic additive chips include: SiO 2 The mass fraction of the powder is 2500ppm, and the rest is isophthalic acid-modified polyethylene terephthalate (the molar ratio of isophthalic acid is 16%).

[0088] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com