Method for producing laminate, and laminate

A technology of a laminate and a manufacturing method, which is applied in the manufacture of printed circuit precursors, printed circuit manufacturing, lamination, etc., can solve the problems of air and foreign matter mixing, increase in peel strength, and bellows effect, etc. The effect of easy peeling and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

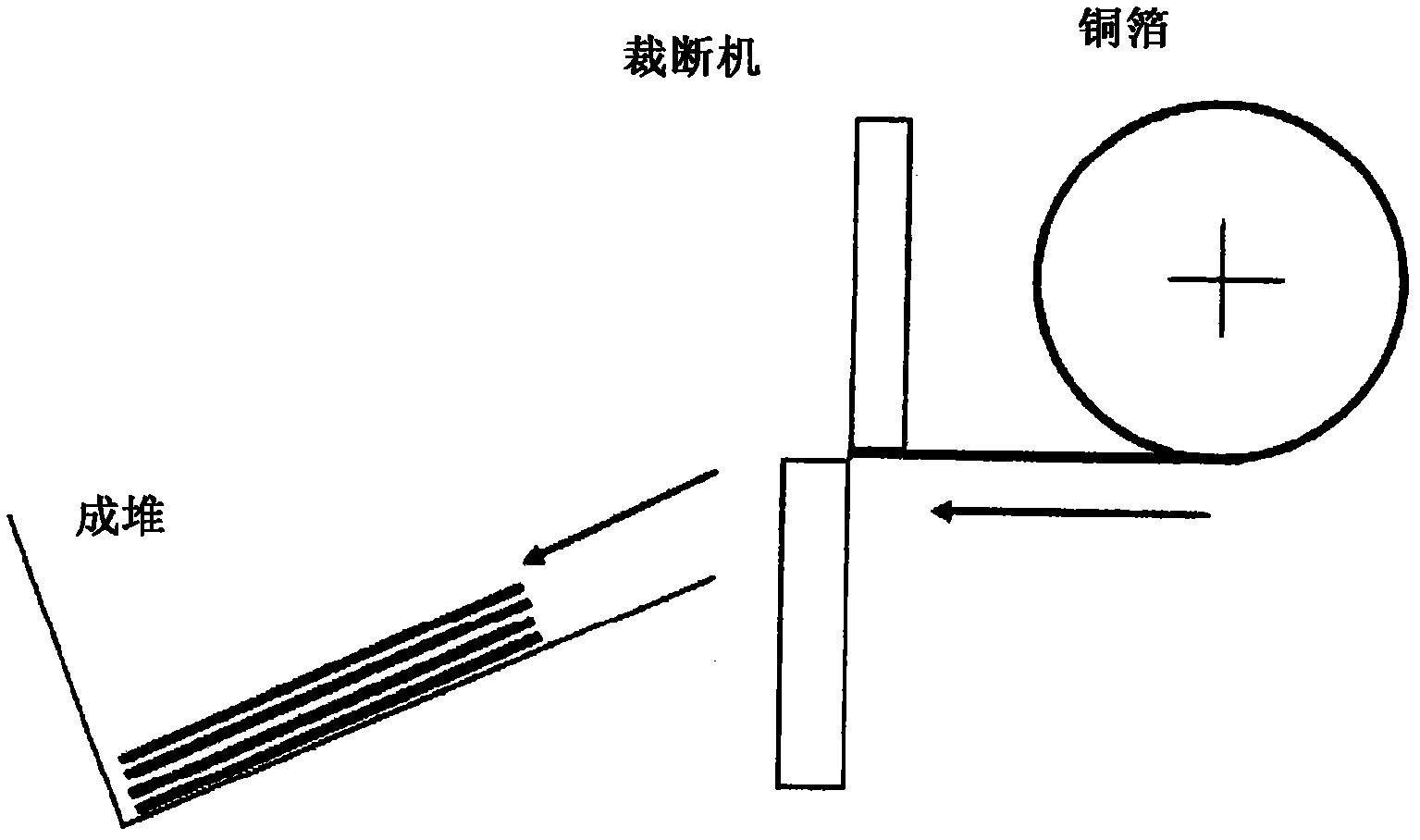

[0140] A 40 μm aluminum foil was used for the carrier A, and a 35 μm copper foil was used as a foil to be bonded thereto. Using an adhesive with a viscosity of 2 million to 3 million mPa·s, the carrier A was unwound from the bobbin and coated with a width of 3 mm on opposite ends. Apply in a linear form.

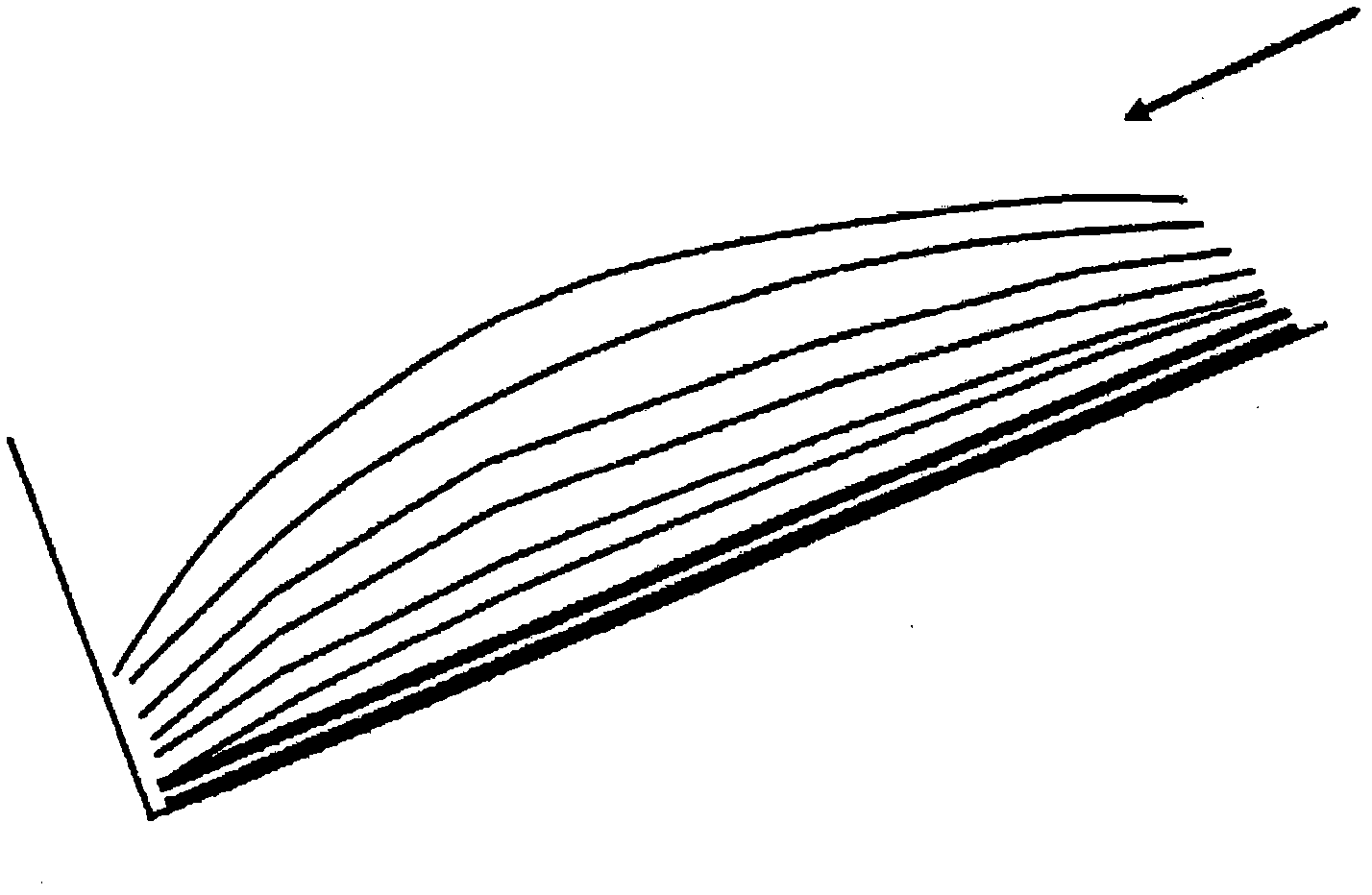

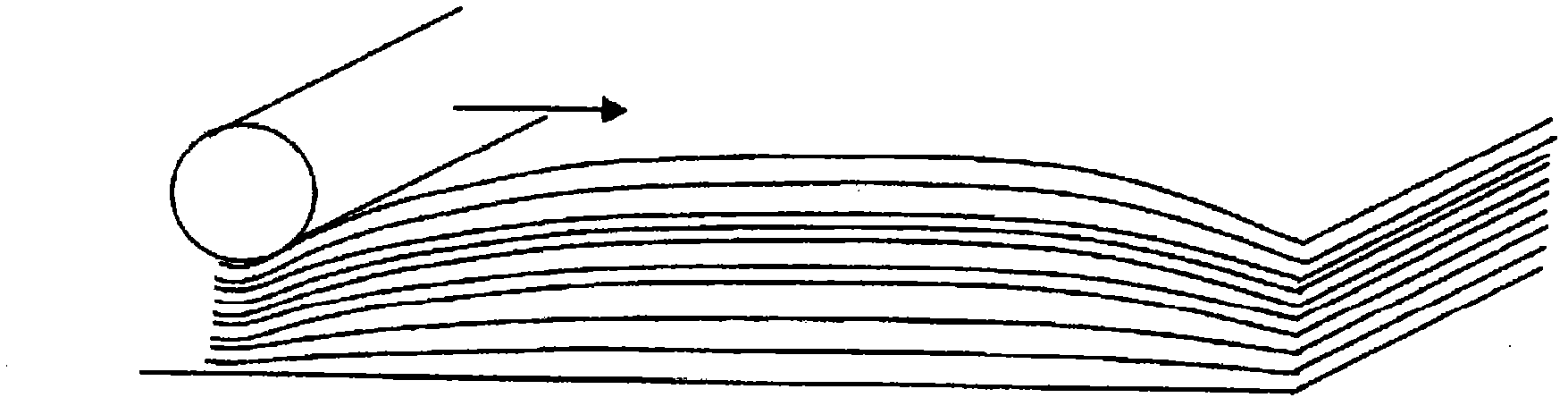

[0141] On the side where the adhesive is applied, metal foil B is stacked while being unwound from the bobbin, the two are bonded, and then cut, and the cut laminates are piled up, starting from the upper part of the cut product. Add rollers (air removal).

[0142] As a result, if the viscosity is 2 million to 3 million mPa·s, it can be pasted without causing wrinkles or cracks.

[0143] In addition, when the viscosity was 5 million mPa·s, wrinkles occurred, and problems occurred in the laminated body.

Embodiment 2

[0145] A 12 μm aluminum foil was used for the carrier A, and a 9 μm copper foil was used as a foil to be bonded thereto. Use an adhesive with a viscosity of 800,000-900,000 mPa·s, and the coating width is 3 mm. Apply in a linear form. The procedure for bonding to the adding roll was the same as in Example 1.

[0146] Since the carrier or copper foil is thin, if the viscosity is lower than that of Example 1, that is, 800,000 to 900,000 mPa·s, some waviness will be observed, but it can be pasted without wrinkles or cracks.

[0147] On the other hand, when the viscosity was 2,000,000 mPa·s, wrinkling occurred and a problem occurred in the laminated body.

[0148] It can be seen from this that the viscosity of the applied adhesive needs to be adjusted according to the material and thickness of the carrier A used.

Embodiment 3

[0150] A copper foil of 18 μm was used for the carrier A, and a copper foil of 5 μm was used as a foil to be bonded thereto. Apply the adhesive in a 3 mm wide line. The process of sticking to the adding roll is the same as in Example 1.

[0151] In this case, since the copper foil is thinner than that of Example 2, if the viscosity is 8000-10000 mPa·s, some waviness is observed, but it can be pasted without causing wrinkles or cracks.

[0152] On the other hand, when the viscosity is 1,500,000 mPa·s, wrinkles and cracks are generated, and a problem occurs in the laminated body.

[0153] It can be seen from this that the viscosity of the applied adhesive needs to be adjusted according to the material and thickness of the carrier A used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com