Method, optical mask and photoreaction layer for making substrate of color filter

A color filter and manufacturing method technology, applied in the direction of filter, optics, optical components, etc., can solve the problems of inconsistent height and pixel ActiveArea area, complicated process, light leakage, etc., to improve contrast and light transmittance, The effect of shortening cycle times and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

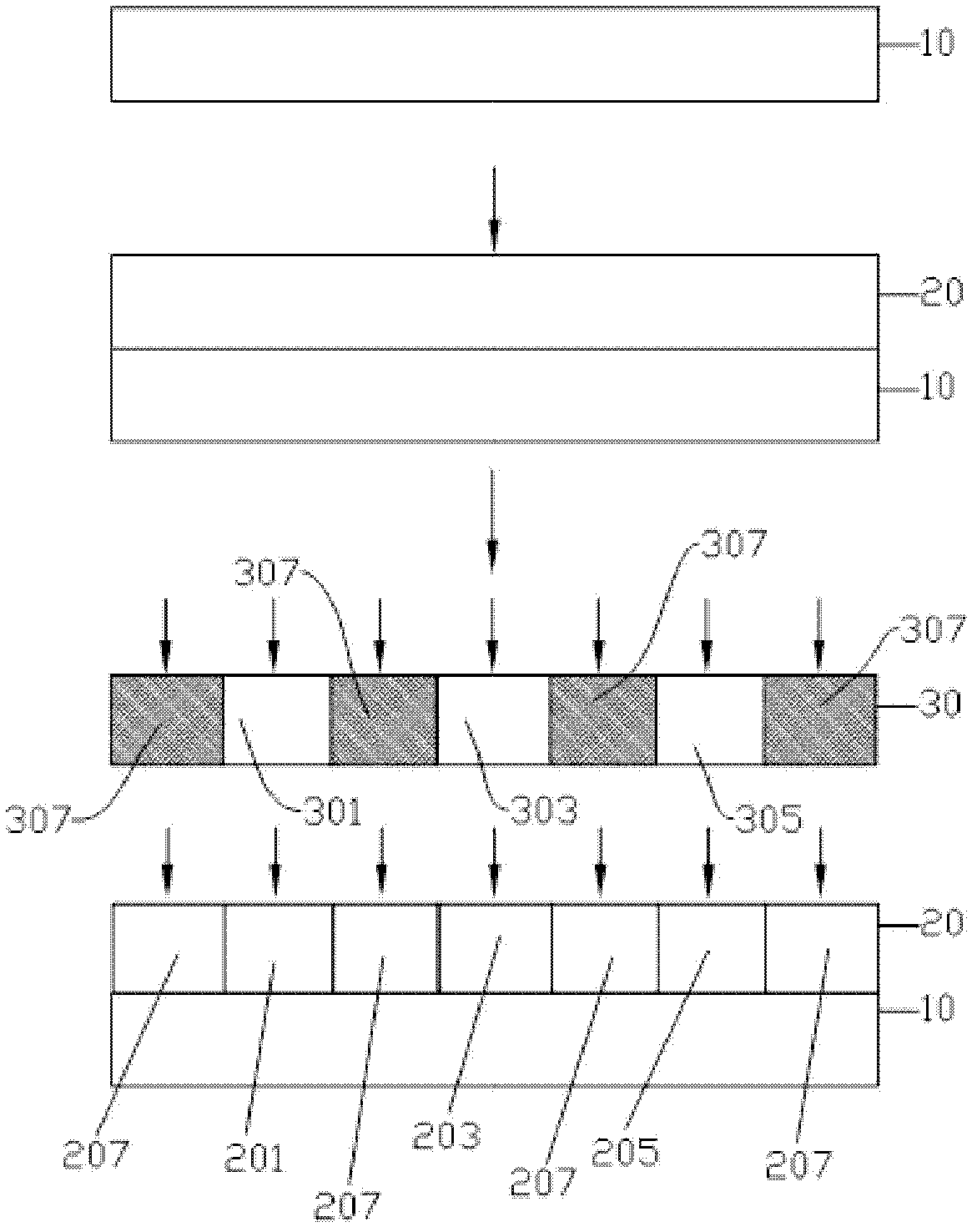

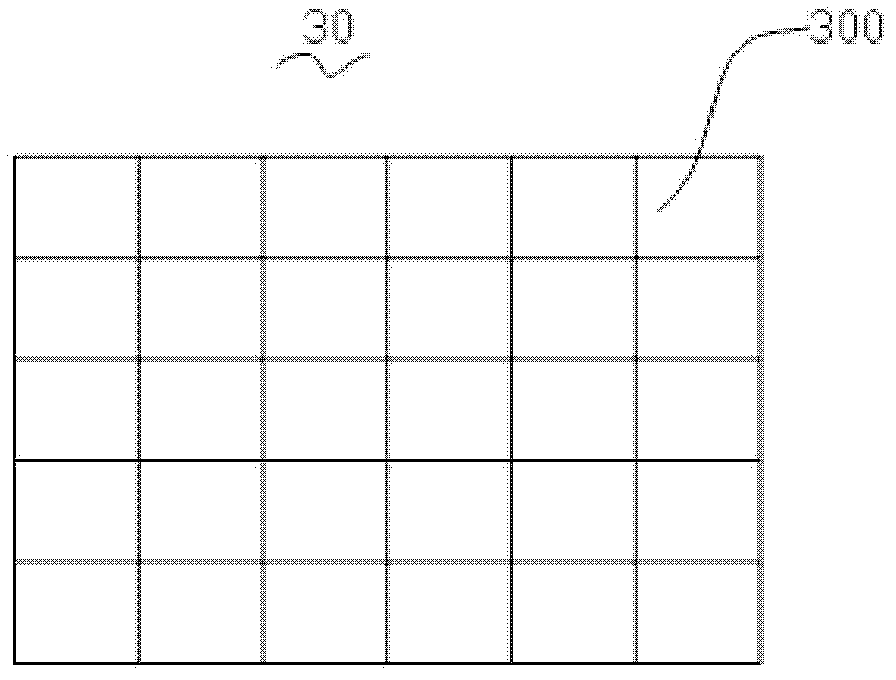

[0069] In addition, the present invention also has other specific implementation modes, for example: the first frequency band light transmission area 301, the second frequency band light transmission area 303 and the third frequency band light transmission area 305 are correspondingly set in the first light transmission area of the optical mask 30 A laser diode with a single wavelength that emits light in the first frequency band, light in the second frequency band, and light in the third frequency band is used as a light source to irradiate the photoreactive layer 20; The single-wavelength laser diodes of the light of the first frequency band, the light of the second frequency band and the light of the third frequency band are used as light sources to irradiate the second light-transmitting region 307 .

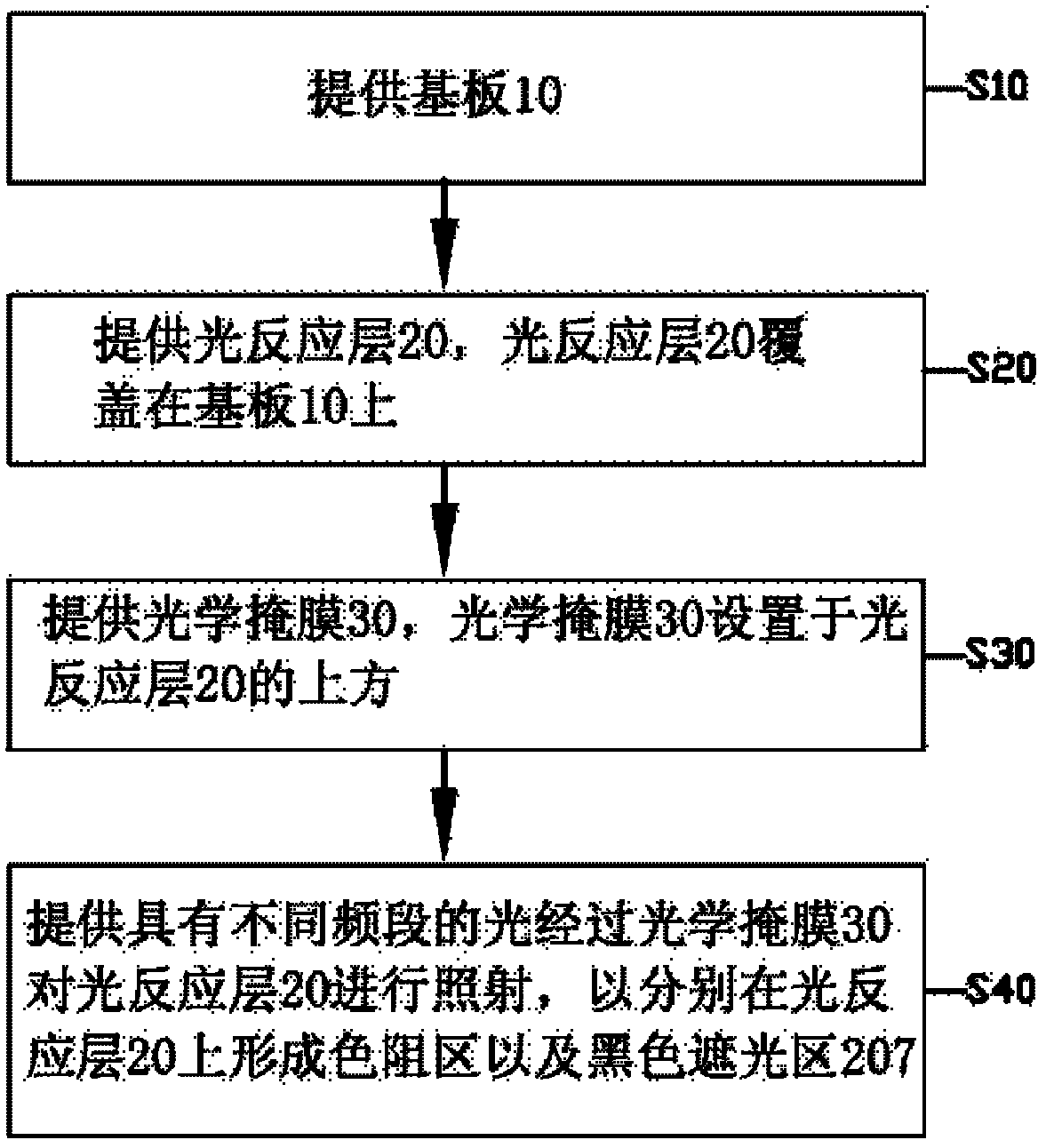

[0070] Different from the prior art, the present invention covers the photoreactive layer 20 on the substrate 10, and arranges the optical mask 30 above the photoreactive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com