Thermochemical hydrogen production system based on microwave heating and hydrogen production method and application thereof

A technology of microwave heating and hydrogen production system, which is applied in the fields of chemical instruments and methods, inorganic chemistry, hydrogen, etc. It can solve the problems of catalyst sintering deactivation, high economic cost, and lengthy heating time, etc., and achieve shortened cycle time and low energy consumption , Reduce the effect of radiation heat loss and heat dissipation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

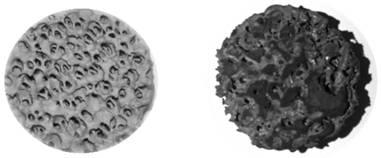

Image

Examples

no. 1 example

[0062] first embodiment ,refer to figure 1 , an example of a thermochemical hydrogen production device based on microwave heating designed in the present invention, including a carrier gas storage device 1, a flow controller 2, a preheater 3, a first three-way valve 4, a second three-way valve 5, a microwave Generating device 6, reactor 7, condenser 9, drying device 10, chromatograph 11, collecting device 12, steam generator 13, superheater 14, resistance furnace 15 and piping systems for connecting various equipment.

[0063] Wherein, the inlet of the preheater 3 communicates with the carrier gas storage device 1, and a flow controller 2 is arranged between them. The carrier gas storage device 1 is used to store nitrogen, inert gas, etc., and the main function of the carrier gas is to carry the water vapor generated by the steam generator 13 .

[0064] The outlet of the preheater 3 communicates with the inlet of the steam generator 13 and one end of the second three-way va...

no. 2 example

[0069] second embodiment , the condenser is a jacketed structure, the jacket is provided with a water inlet and a water outlet, and the circulation of the condensate in the jacket can be realized through a pumping device. The lower end of the condenser also includes a trap for storing liquid water condensed from the gaseous products. Since the oxygen / hydrogen gas from the reactor is generated at high temperature during the reaction process, it is necessary to cool down these gases before collecting them to ensure the safety of gas storage; in addition, hydrogen will also contain some unreacted Therefore, it is necessary to remove the water vapor through condensation to ensure the purity of the collected hydrogen.

no. 3 example

[0070] third embodiment , the drying device 10 adopts a water removal device, and the water removal device is a container filled with discoloration silica gel, and the gaseous product enters the water removal device under the push of the carrier gas to realize dehydration. Since the hydrolysis reaction of hydrogen production requires superheated steam to react with metal oxides in a low oxidation state, the obtained hydrogen contains unreacted water vapor. In order to ensure the purity of the collected hydrogen, it is necessary to A drying device is further used to ensure that the hydrogen is dry.

[0071] Fourth embodiment , the reactor is made of quartz, since the reactor is a place for thermal reduction reaction, the reactor needs to be able to withstand the temperature environment required for the reaction, and the high temperature resistance of quartz can well meet the above conditions.

[0072] fifth embodiment, the connecting pipes between the reactor inlet and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com