Proportional steam trap with floating ball automatic adjustment function

An automatic adjustment and steam trap technology, which is applied in steam traps, chemical instruments and methods, filtration and separation, etc., can solve problems affecting the safety of use, frequent opening actions, and affecting sealing effects, etc., to prolong life and facilitate cleaning and maintenance , the effect of preventing backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

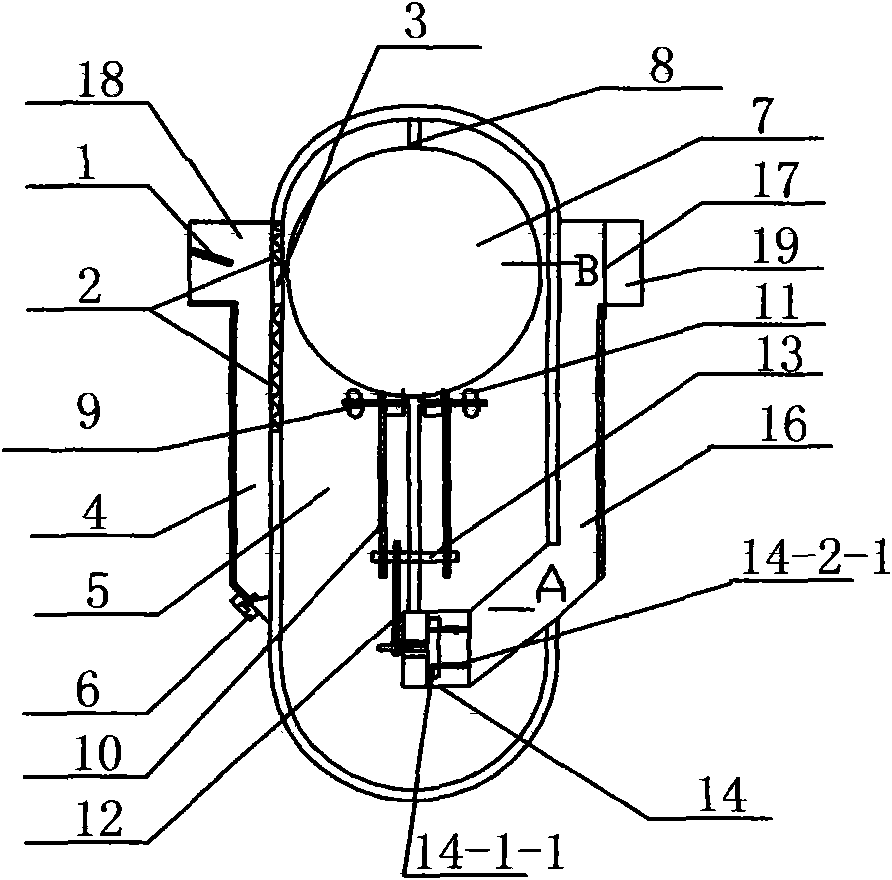

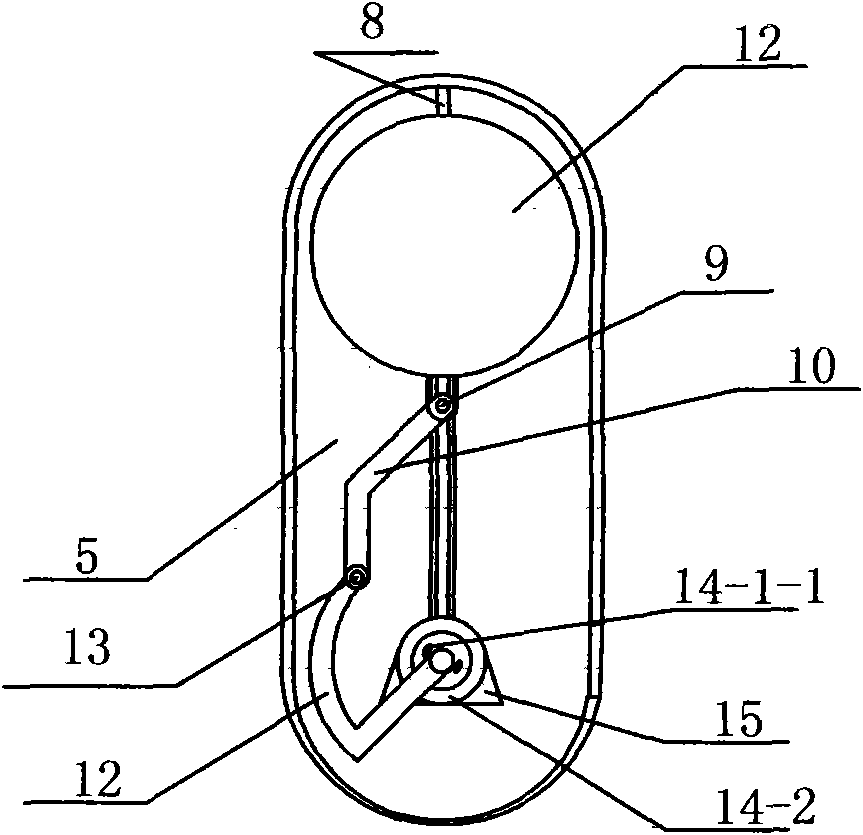

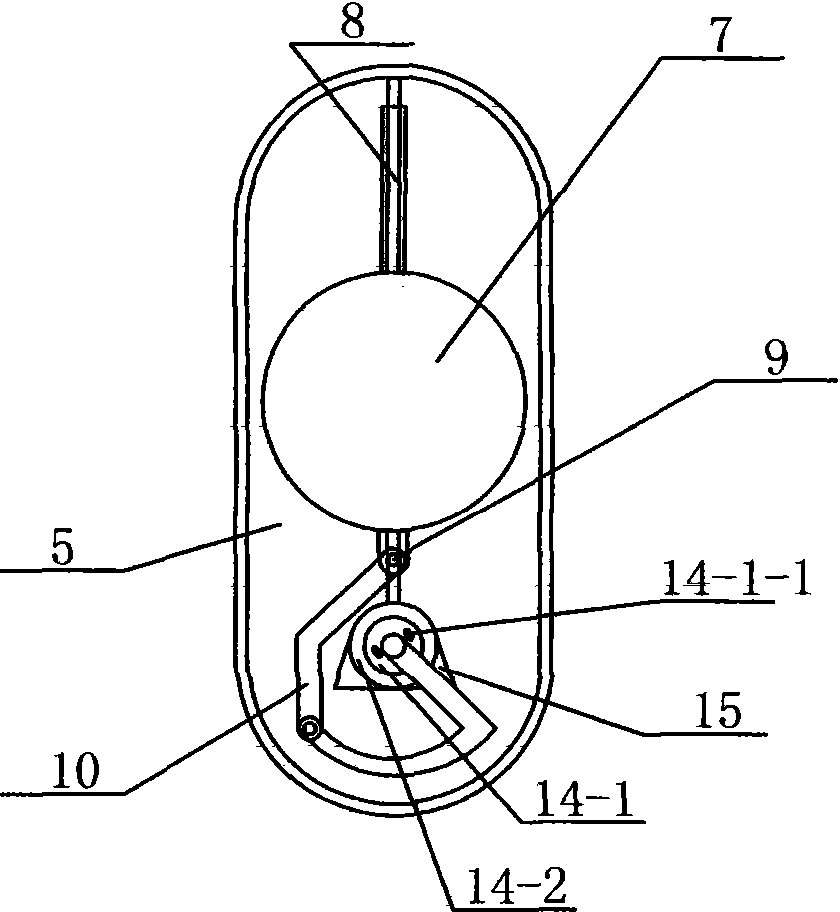

[0012] refer to Figure 1-5 , the specific embodiment adopts the following technical solutions: it consists of a splitter 1, a filter screen 2, a water retaining plate 3, a slag storage tank 4, a liquid storage chamber 5, a sealing cover 6, a floating ball 7, a positioning rod 8, a connecting rod shaft 9. Composition of counterweight 10, connecting rod 11, lever rocker arm 12, lever rocker arm shaft 13, rotary valve core device 14, diversion cover 15, diversion pipe 16, non-return piece 17, inlet pipe 18 and outlet pipe 19 , the splitter 1 is arranged in the inlet pipe 18, the bottom of the inlet pipe 18 is provided with a slag storage tank 4, the bottom of the slag storage tank 4 is provided with a sealing cover 6, the right side of the inlet pipe 18 is provided with a filter screen 2, and the filter screen 2 is provided with a water retaining plate 3, and the right side of the filter screen 2 is provided with a liquid storage chamber 5, and a floating ball 7 is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com