Easy-to-replace projection welding electrode

An electrode and fixed electrode technology, which is applied in the field of automobile parts manufacturing, can solve the problem that the projection welding electrode is not easy to replace, and achieve the effect of ensuring the airtightness of the system, high matching accuracy and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

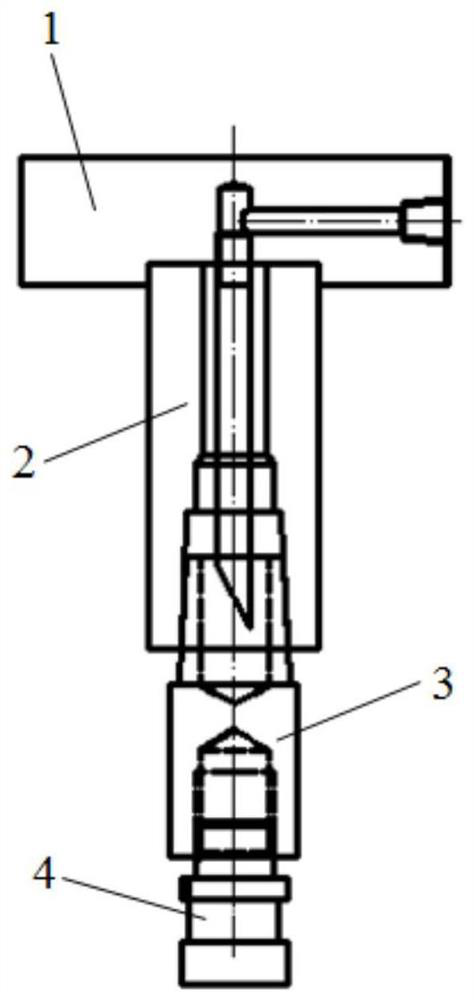

[0033] Such as figure 1 An easily replaceable projection welding electrode shown, consisting of a Figure 5 The shown upper electrode mounting base 1, upper electrode worm 2, upper fixed electrode 3, cooling water system and such as Image 6 The upper connection electrode 4 is shown; the upper electrode mounting base 1 is fixedly connected with the upper electrode worm 2, and the upper electrode worm 2 is connected with the upper fixed electrode 3; the bottom of the upper fixed electrode 3 is provided with an internal thread installation hole 5, and the upper The top of the connecting electrode 4 is provided with an externally threaded mounting platform 6 , and the upper fixed electrode 3 is detachably connected to the upper connecting electrode 4 through the internally threaded mounting hole 5 and the externally threaded mounting platform 6 . In the internal thread in the internal thread mounting hole 5 and the external thread on the external thread mounting table 6, the thr...

Embodiment 2

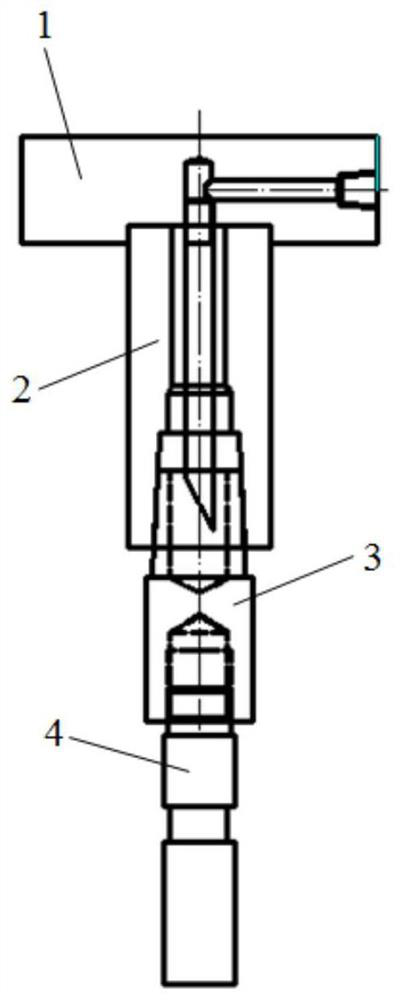

[0038] Such as figure 2 An easily replaceable projection welding electrode shown, consisting of a Figure 5 The shown upper electrode mounting base 1, upper electrode worm 2, upper fixed electrode 3, cooling water system and such as Figure 7 The upper connection electrode 4 is shown; the upper electrode mounting base 1 is fixedly connected with the upper electrode worm 2, and the upper electrode worm 2 is connected with the upper fixed electrode 3; the bottom of the upper fixed electrode 3 is provided with an internal thread installation hole 5, and the upper The top of the connecting electrode 4 is provided with an externally threaded mounting platform 6 , and the upper fixed electrode 3 is detachably connected to the upper connecting electrode 4 through the internally threaded mounting hole 5 and the externally threaded mounting platform 6 . In the internal thread in the internal thread mounting hole 5 and the external thread on the external thread mounting table 6, the t...

Embodiment 3

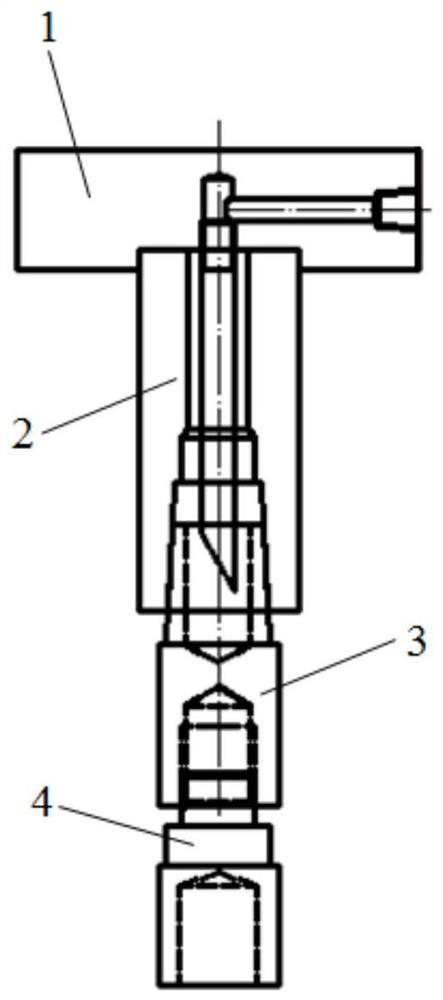

[0040] Such as image 3 An easily replaceable projection welding electrode shown, consisting of a Figure 5 The shown upper electrode mounting base 1, upper electrode worm 2, upper fixed electrode 3, cooling water system and such as Figure 8The upper connection electrode 4 is shown; wherein the upper electrode mounting seat 1 is fixedly connected with the upper electrode worm 2, and the upper electrode worm 2 is connected with the upper fixed electrode 3; The top of the connecting electrode 4 is provided with an externally threaded mounting platform 6 , and the upper fixed electrode 3 is detachably connected to the upper connecting electrode 4 through the internally threaded mounting hole 5 and the externally threaded mounting platform 6 . In the internal thread in the internal thread mounting hole 5 and the external thread on the external thread mounting table 6, the thread diameter is 18mm, and the pitch is 1.25mm.

[0041] The upper connection electrode 4 includes a supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com