Formula and preparation method of 180 DEG C temperature and salt resistant drilling fluid with strong inhibition and high density

A technology with strong inhibition and high density, applied in the field of oil drilling drilling fluid, can solve the problems of poor anti-pollution performance, large filtration loss, and difficult control of drilling fluid viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

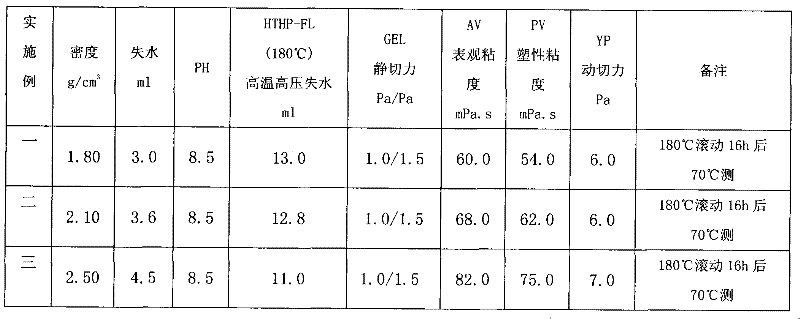

Examples

Embodiment 1

[0019] Embodiment one, according to the drilling fluid formula component 3kg / m 3 Soda ash, 30kg / m 3 High temperature anti-salt cutting agent, 0.5kg / m 3 Flow regulator, 10kg / m 3 Filtrate reducer A, 20kg / m 3 Filtrate reducer B, 50kg / m 3 Inhibiting anti-slump agent, 40kg / m 3 Inhibit lubricant, 1000kg / m 3 Strong inhibition of high density water-soluble weighting agent, 595kg / m 3 Inert weighting agent, each component is selected from the components described in the previous technical scheme, wherein the inert weighting agent is selected from barite BaSO 4 ,

[0020] The preparation method of embodiment one, according to the component of above-mentioned drilling fluid formula, take the following steps:

[0021] (1) Measure and calculate the amount of fresh water required to prepare the drilling fluid, at a stirring speed of 12000 rpm, press 3kg / m in fresh water 3 The concentration of soda ash is added, stirred for 10 minutes, and then press 30kg / m 3 Add the high-temperatur...

Embodiment 2

[0027] Embodiment two, according to drilling fluid formula component 3kg / m 3 Soda ash, 31kg / m 3 High temperature anti-salt cutting agent, 0.5kg / m 3Flow regulator, 11kg / m 3 Fluid loss reducer A, 22kg / m 3 Filtrate reducer B, 55kg / m 3 Inhibiting anti-slump agent, 40kg / m 3 Inhibit lubricant, 1000kg / m 3 Strong suppression high-density water-soluble weighting agent, 1280kg / m 3 Inert weighting agent, each component is selected from the components described in the previous technical scheme, wherein the inert weighting agent is selected from barite BaSO 4 ;

[0028] The preparation method of embodiment two, according to the component of above-mentioned drilling fluid formula, take the following steps:

[0029] (1) Measure and calculate the amount of fresh water required to prepare the drilling fluid, at a stirring speed of 12000 rpm, press 3kg / m in fresh water 3 The concentration of soda ash is added, stirred for 10 minutes, and then press 31kg / m 3 Add the high-temperature an...

Embodiment 3

[0035] Embodiment three, according to drilling fluid formula component 4kg / m 3 Soda ash, 30kg / m 3 High temperature anti-salt cutting agent, 0.5kg / m 3 Flow regulator, 10kg / m 3 Filtrate reducer A, 20kg / m 3 Filtrate reducer B, 50kg / m 3 Inhibiting anti-slump agent, 40kg / m 3 Inhibit lubricant, 1000kg / m 3 Strongly suppressed high-density water-soluble weighting agent, 2569kg / m 3 Inert weighting agent, each component is selected from the components described in the previous technical scheme, wherein the inert weighting agent is selected from ilmenite powder;

[0036] The preparation method of embodiment three, according to the component of above-mentioned drilling fluid formula, take the following steps:

[0037] (1) Measure and calculate the amount of fresh water needed to prepare the drilling fluid, at a stirring speed of 12000 rpm, press 4kg / m in fresh water 3 The concentration of soda ash is added, stirred for 10 minutes, and then press 30kg / m 3 Add the high-temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com