Strong-inhibition and strong-cementation well wall stabilizer and preparation method thereof

A technology of wellbore stabilizer and strong inhibition, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor cementing quality, difficult to achieve wellbore stability, high cost, etc., and achieve convenient control of the preparation process , Good wellbore stabilization effect, stable product quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

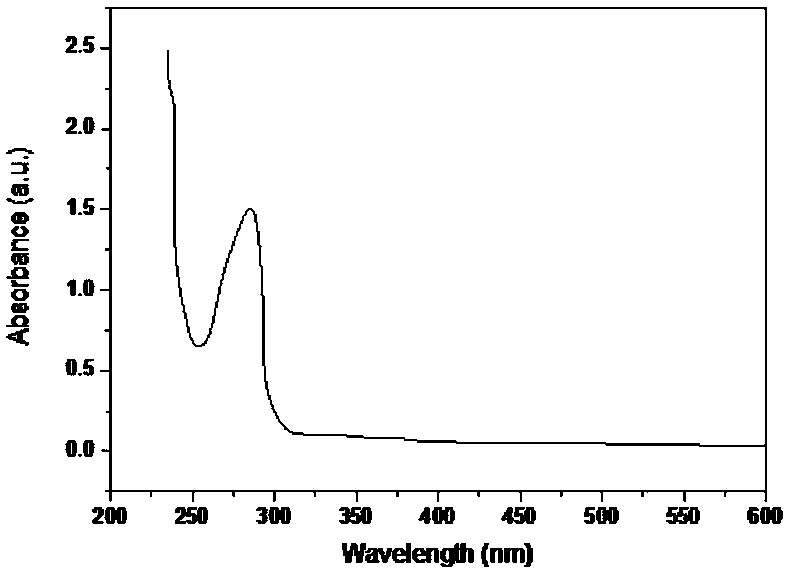

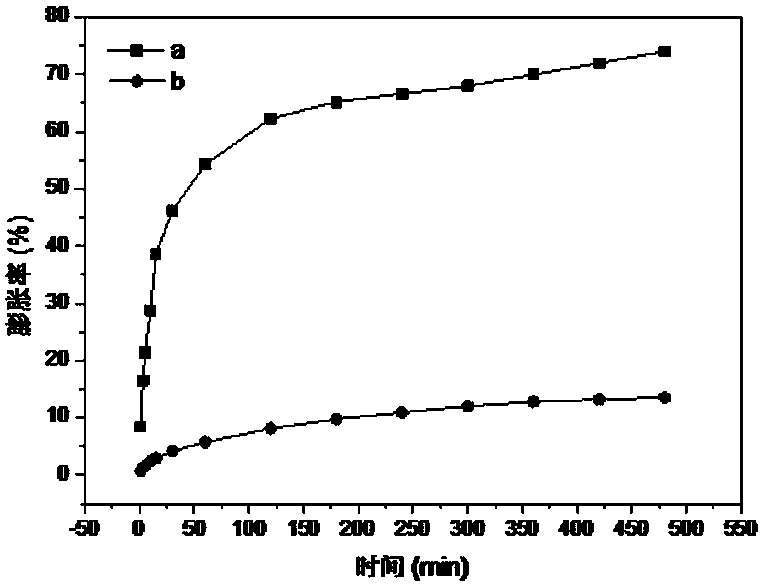

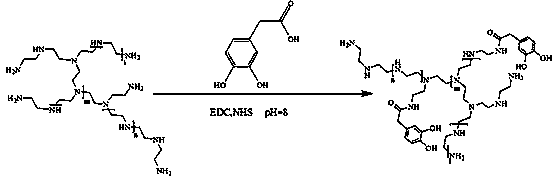

[0038] Embodiment 1: a kind of strong inhibition that the present invention mentions, strong cementation well wall stabilizer and preparation method thereof, comprises the following steps:

[0039] 3,4-dihydroxyphenylpropionic acid (2.65g, 14.5mmol) was dissolved in 5mL of DMF, and added to 10mL of 50% EDC (5.55g, 29mmol) in methanol solution to activate for half an hour. Branched PEI (Mw=25k) (5 g, 29 mmol) was dissolved in 10 mL of methanol solution, then added dropwise into the activated mixed solution, and stirred for 12 h. The product was purified twice by precipitation with ether, dialyzed in hydrochloric acid with a pH of 4 for two days, dialyzed in deionized water for 2 hours (molecular weight cut-off: 10,000), and freeze-dried. Then it was added to 196 mL of 0.2 mol / L phosphate buffer solution (pH 8), and the concentration of PEI-C in the final system was adjusted to 1 mg / mL. The solution was maintained for 24 hours to make it fully cross-linked, and then it was dial...

Embodiment 2

[0071] Embodiment 2: a kind of strong inhibition mentioned in the present invention, strong cementation well wall stabilizer and preparation method thereof, comprises the following steps:

[0072] 3,4-Dihydroxyphenylacetic acid (2.65g, 14.5mmol) was dissolved in 5mL of DMF, and added to 10mL of 50% N-hydroxysuccinimide (NHS) (5.55g, 29mmol) methanol solution to activate half an hour. Branched (polyethyleneimine) PEI (Mw=25k) (5g, 29mmol) was dissolved in 10mL of methanol solution, then added dropwise to the activated mixed solution, and stirred for 12h. The product was purified twice by precipitation with ether, dialyzed in formic acid with a pH of 4 for two days, dialyzed in deionized water for 2 hours (molecular weight cut-off: 10,000), and freeze-dried. Then it was added to 196 mL of 0.2 mol / L borate buffer solution (pH 8), and the concentration of PEI-C in the final system was adjusted to 1 mg / mL. The solution was maintained for 24 hours to make it fully cross-linked, an...

Embodiment 3

[0073] Embodiment 3: a kind of strong inhibition that the present invention mentions, strong cementation well wall stabilizer and preparation method thereof, comprises the following steps:

[0074] 3,4-dihydroxybenzoic acid (2.65 g, 14.5 mmol) was dissolved in 6 mL of ethanol, and added to 10 mL of 51% 2-(N-morpholine)ethanesulfonic acid monohydrate (MES) (5.55 g, 29mmol) in methanol solution for half an hour. Branched (polyethyleneimine) PEI (Mw=25k) (5g, 29mmol) was dissolved in 10mL of methanol solution, then added dropwise to the activated mixed solution, and stirred for 12h. The product was purified twice by precipitation with ether, dialyzed in chloroform with a pH of 4 for two days, dialyzed in deionized water for 2 hours (molecular weight cut-off: 10,000), and freeze-dried. Then it was added to 196 mL of 0.2 mol / L tris buffer solution (pH 8), and the concentration of PEI-C in the final system was adjusted to 1 mg / mL. The solution was maintained for 24 hours to make i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com