Strong-plugging hydrophobic high-performance water-based drilling fluid

A water-based drilling fluid and hydrophobic technology, which is applied in the field of petroleum drilling engineering, can solve the problems of drill sticking due to the accumulation of cuttings beds, insufficient lubrication and anti-sticking ability, and restrictions on the exploration and development of tight gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] 1.1 Preparation of aqueous monomer solution: add 40 mL of deionized water to a beaker, and mix the dimethyl carbonate (DMC), acrylamide (AM), acrylic acid (AA), dimethylaminoethyl methacrylate (DMAEMA) The four monomers are weighed according to the total monomer mass of 20% (8.0g), and the monomer mass ratio is 1:3:2:4 (0.8g:2.4g:1.6g:3.2g), under ice bath conditions Dissolve in a beaker, add 0.5g of sodium hydroxide, use pH test paper to adjust the pH value of the solution to about 7, use a magnetic stirrer to stir for 10 to 30 minutes, and stir evenly to obtain the inner phase.

[0078] 1.2 Preparation of oil phase solution: add 60mL 3# white oil to a beaker, then add 3% emulsifier Span 80 (1.8g), stir with a magnetic stirrer for 10-20 minutes until the emulsifier is fully dissolved, and the oil phase is obtained .

[0079] 1.3 Preparation of emulsion: After cleaning the high-speed shear emulsifier, pour the oil phase into a large beaker, and place the beaker in an i...

Embodiment 2

[0086] 2.1 First add 100mL of distilled water to a three-necked flask, add 0.5% (0.5g) of silicon dioxide powder, add 1% (1.0g) of silane coupling agent KH550, and stir at room temperature for 30 minutes at high speed.

[0087] 2.2 Gradually add 2.0 g of cetyl acrylate monomer and 8.0 g of acrylamide monomer into the three-necked flask, mix well, raise the temperature to 65°C, and keep stirring for 4 hours. After the reaction is finished, a liquid hydrophobic plugging and anti-slump agent for drilling fluid can be obtained, which is designated as SFF-1.

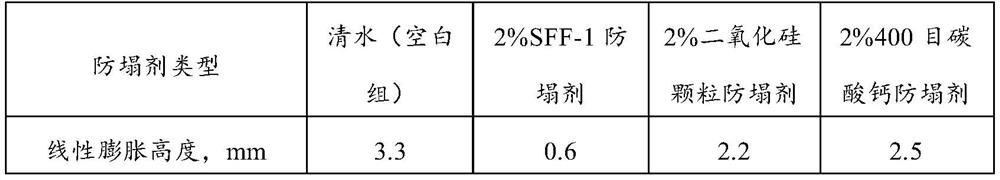

[0088] Evaluation of the anti-slump effect of the hydrophobic type plugging and anti-slump agent SFF-1 for drilling fluid obtained in Example 2:

[0089] Hydrophobic plugging and anti-slump agent SFF-1 for drilling fluid improves the anti-slump effect through two aspects. On the one hand, through the rigid plugging effect of silica particles, it plugs the micro-cracks and micro-pores of the well wall and prevents water from e...

Embodiment 3

[0093] 3.1 First, add 100mL of distilled water to a three-necked flask, add 0.2% (0.2g) of nano-ferric oxide powder, add 1.5% (1.5g) of silane coupling agent KH560, and stir at room temperature for 30 minutes at high speed.

[0094] 3.2 Gradually add 2.0g of myristyl acrylate monomer, 4.0g of acrylamide monomer, and 4.0g of acrylic acid monomer into a three-necked flask, mix well, raise the temperature to 60°C, and keep stirring for 4 hours. After the reaction is finished, it is dried to obtain the hydrophobic plugging lubricant powder SFR-1 for drilling fluid.

[0095] The performance evaluation of hydrophobic type plugging lubricant SFR-1 for drilling fluid obtained in embodiment 3:

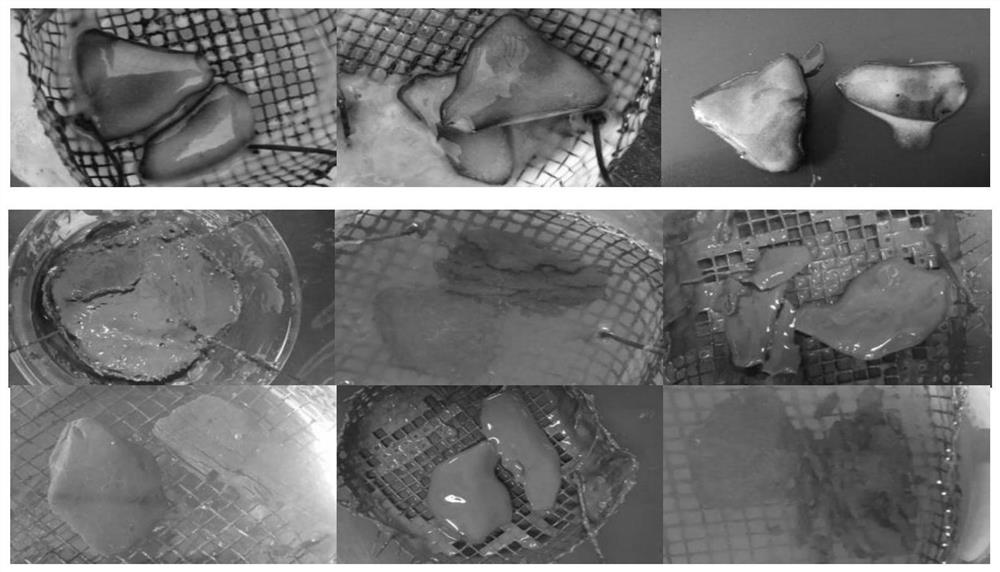

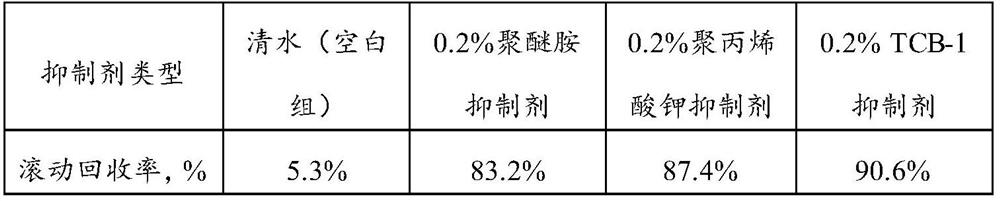

[0096]Hydrophobic plugging lubricant SFR-1 for drilling fluid combines the two aspects of particle rolling and hydrophobicity to improve the lubrication effect, reduce friction and torque. Refer to SY / T 6094-1994 "Evaluation Procedures for Lubricants for Drilling Fluids", the evaluation index ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com