A Construction Method of Shield Tunneling in Dissolved Gully Stratum

A technology of hole entry and shield tunneling, which is applied in earth-moving drilling, mining equipment, tunnels, etc., to prevent sand and water gushing, good promotion prospects, and simple construction procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

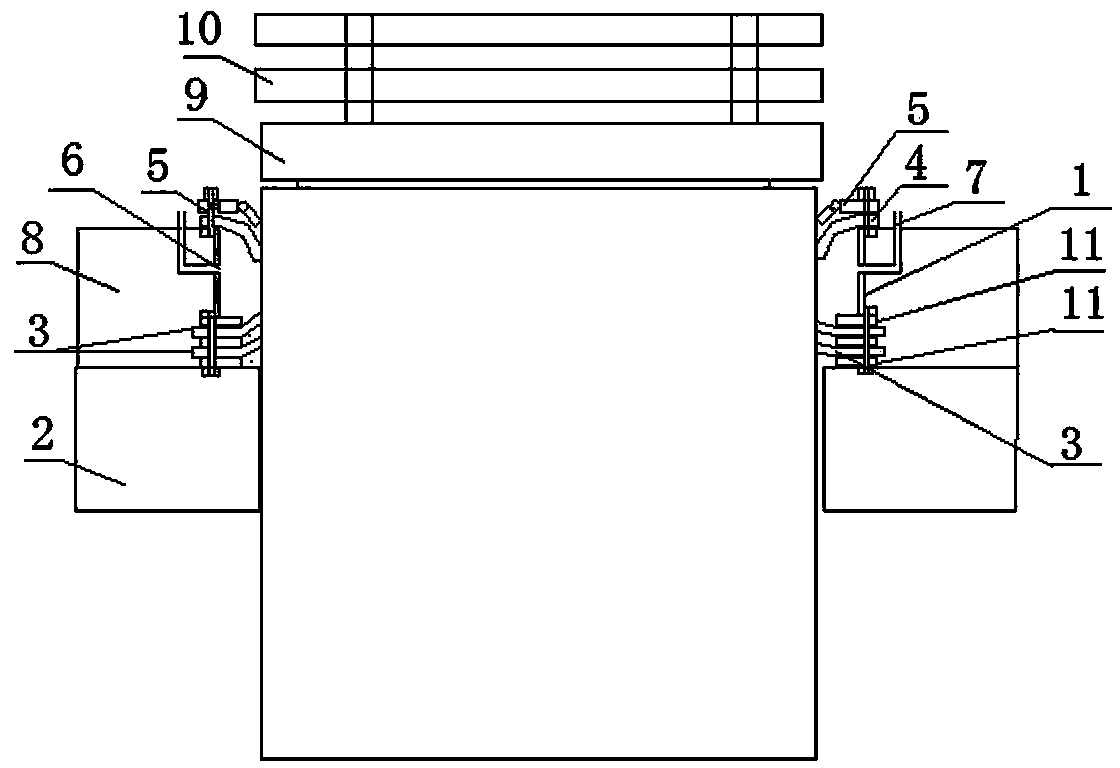

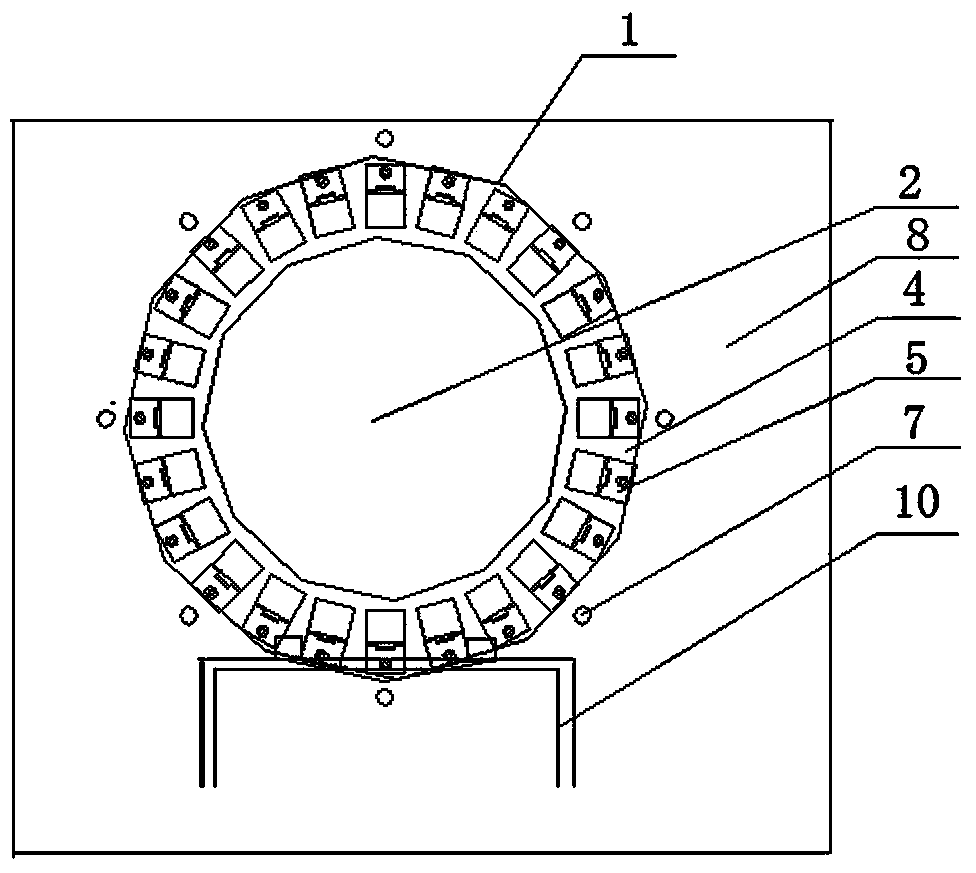

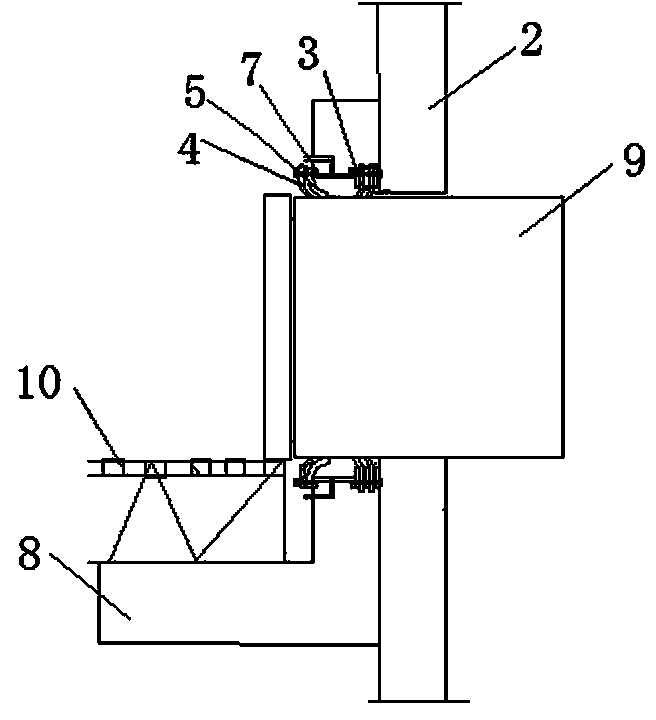

[0036] The non-reinforced shield tunneling construction method described in the present invention is used for the left and right lines of the section from Furong Square Station to Wuyi Square Station on Changsha Metro Line 2. The tunnels in this section are all located in the sand and pebble stratum in the karst ditch section. First, optimize the design of the portal steel ring, and at least one elastic rubber water-stop ring and rubber water-stop curtain are added inside, and positioning and installation are carried out during the construction of the main structure of the station; secondly, when the shield tunnel is fast entering the hole, adjust the posture of the shield tunnel to reduce the tunneling speed Excavate to the enclosure structure. When the shield breaks half of the enclosure structure, open excavation is adopted, and at the same time, stop adding any liquid to the warehouse. Then, when the shield cutter head breaks the enclosure structure, it moves forward quickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com