Aqueous black sheet used for artificial leather and preparation method thereof

A water-based, artificial leather technology, applied in the direction of dyeing, textile and papermaking, dyed polymer organic compound treatment, etc., can solve the problem of difficult to adjust the colorful colors, the coloring effect of water-based artificial leather is not as good, and it cannot be dissolved in water. Artificial leather and other issues, to achieve the effect of easy packaging and storage, easy color matching, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

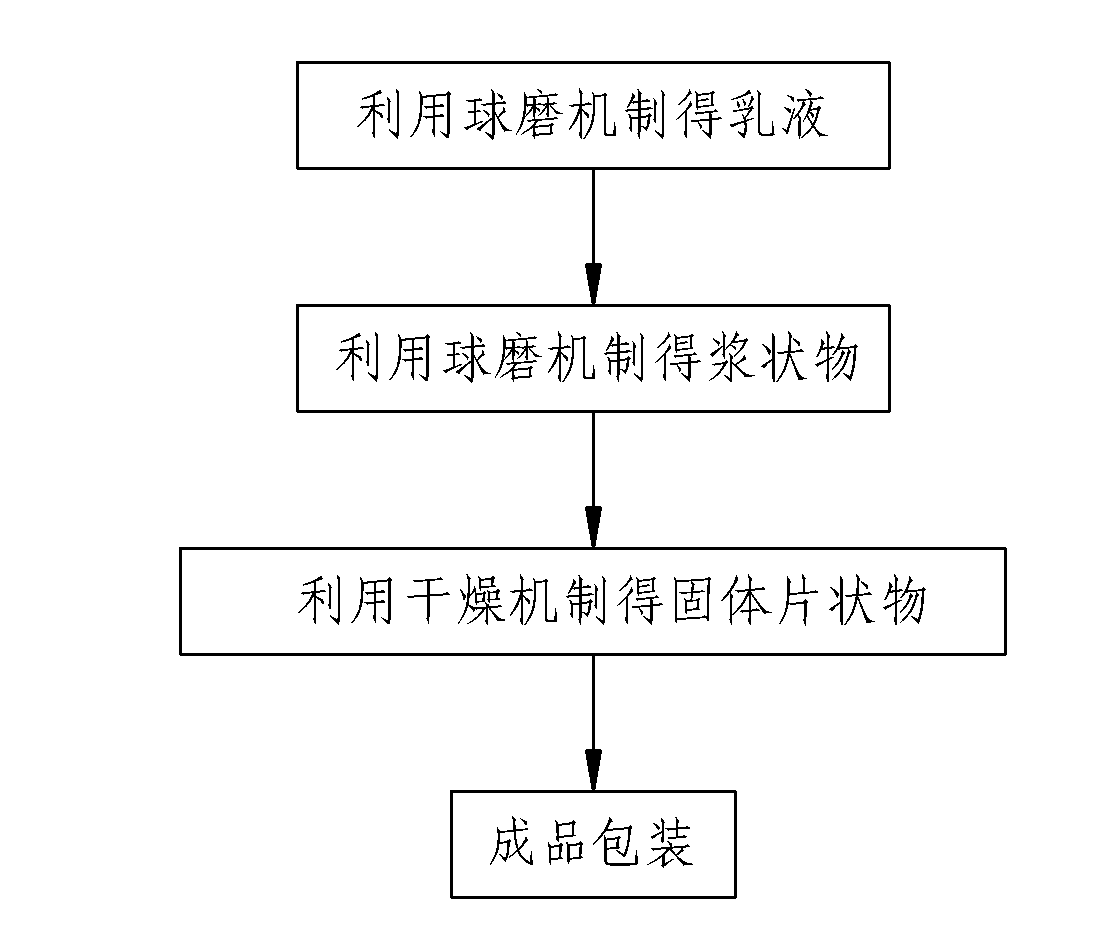

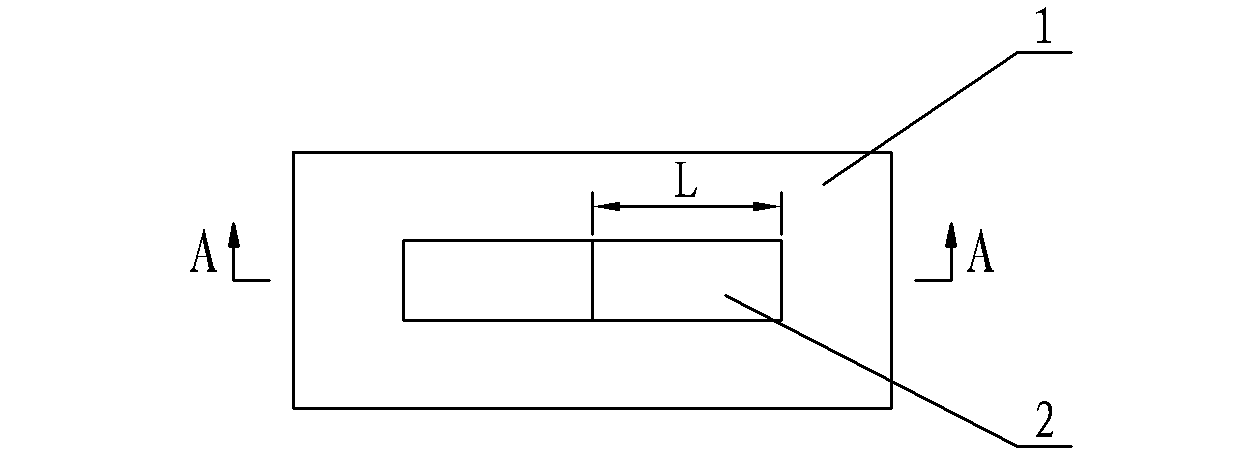

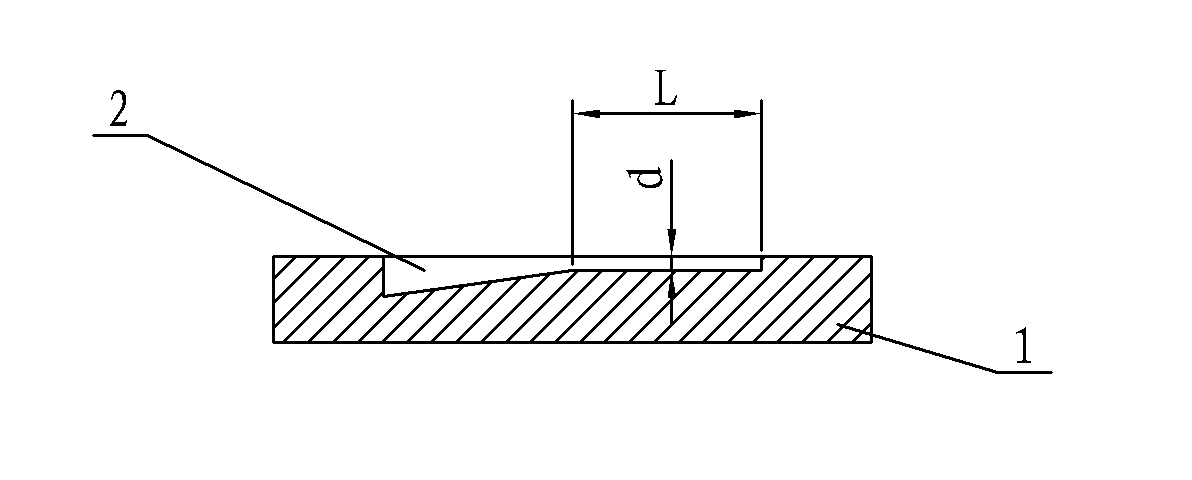

[0018] see figure 1 , artificial leather water-based black color chip, made of the following raw materials in parts by mass: carbon black powder, 1250-1750 parts; styrene-acrylic resin, 2750-3250 parts; ethanolamine, 500 parts; water H 2 O, 5000 copies.

[0019] When making water-based black color chips for artificial leather,

[0020] 1) First weigh: 5000g of water, 500g of ethanolamine, 3250g of styrene-acrylic resin, and 1250g of carbon black powder.

[0021] 2) Pour 5000g of water into the material tank of the ball mill, and then pour 250g of ethanolamine into the water.

[0022] Since ethanolamine releases a large amount of heat when it dissolves, ethanolamine can be added in batches during actual preparation to keep the temperature of the material in the tank at room temperature.

[0023] 3) Slowly pour the styrene-acrylic resin into the material tank, and start the ball mill to stir at the same time, the stirring speed of the ball mill is controlled at about 300rpm; ...

no. 2 example

[0034] When making water-based black color chips for artificial leather,

[0035] 1) First weigh: 5000g of water, 500g of ethanolamine, 3150g of styrene-acrylic resin, and 1350g of carbon black powder.

[0036] 2) Pour 5000g of water into the material tank of the ball mill, and then pour 250g of ethanolamine into the water.

[0037] 3) Slowly pour the styrene-acrylic resin into the material tank, and start the ball mill to stir at the same time, the stirring speed of the ball mill is controlled at about 300rpm; while adding the styrene-acrylic resin, slowly add the remaining 250g of ethanolamine into the material tank During the process, the PH value in the material tank is kept between 9 and 10.

[0038] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

no. 3 example

[0040] When making water-based black color chips for artificial leather,

[0041] 1) First weigh: 5000g of water, 500g of ethanolamine, 2950g of styrene-acrylic resin, and 1550g of carbon black powder.

[0042] 2) Pour 5000g of water into the material tank of the ball mill, and then pour 250g of ethanolamine into the water.

[0043] 3) Slowly pour the styrene-acrylic resin into the material tank, and start the ball mill to stir at the same time, the stirring speed of the ball mill is controlled at about 300rpm; while adding the styrene-acrylic resin, slowly add the remaining 250g of ethanolamine into the material tank During the process, the PH value in the material tank is kept between 9 and 10.

[0044] See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com