Batch preparation method of high-purity salvianolic acid A

A high-purity, salvianolic acid technology, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve problems such as unsatisfactory effects, membrane pore blocking, membrane life, and loss of target compounds. Stable and controllable quality, reduced separation load and acceptable cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

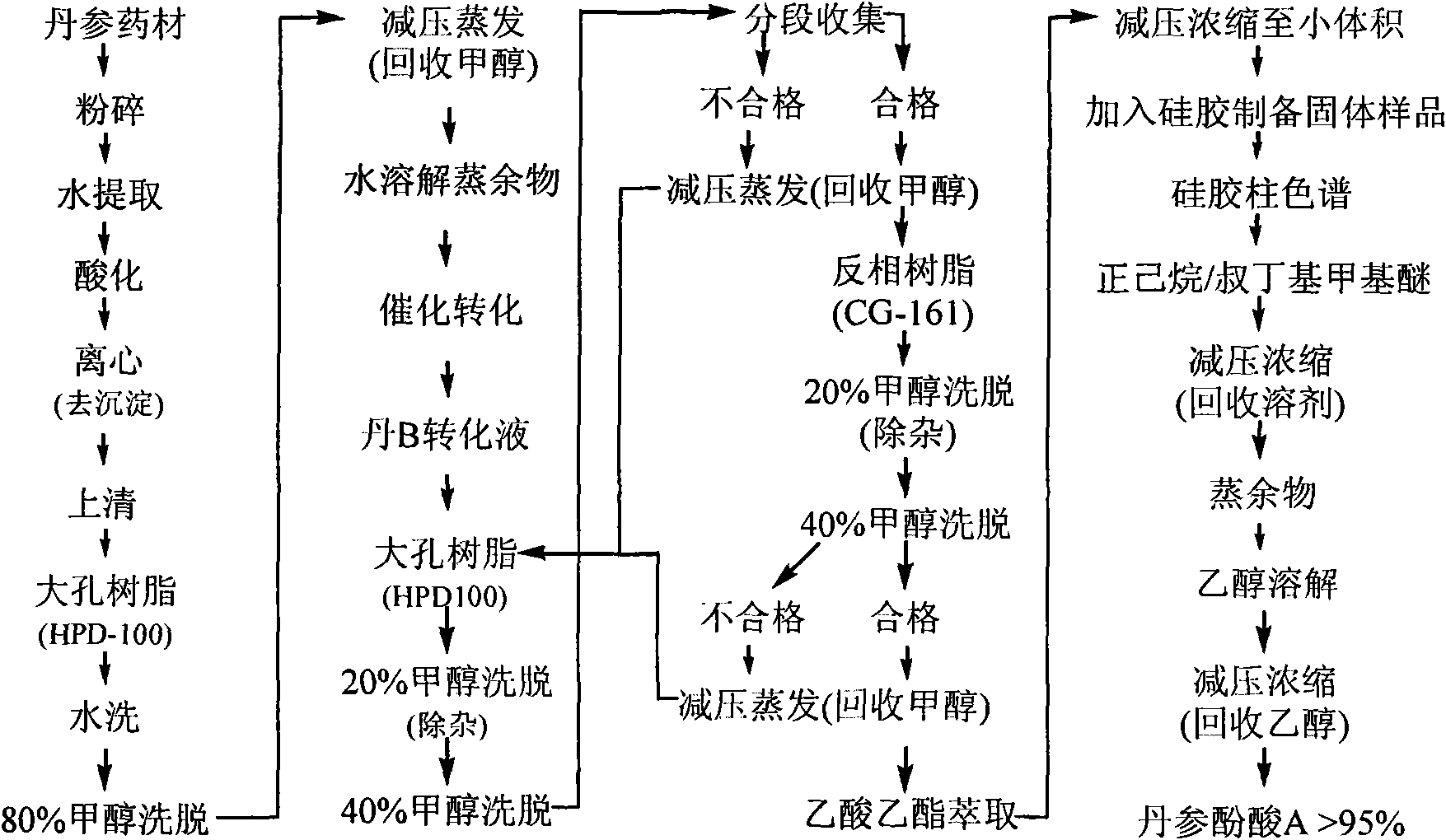

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0053] Through systematic filler screening, unit technology optimization and unit technology combination optimization, the invention provides a batch preparation method of high-purity salvianolic acid A, the process comprising the following steps:

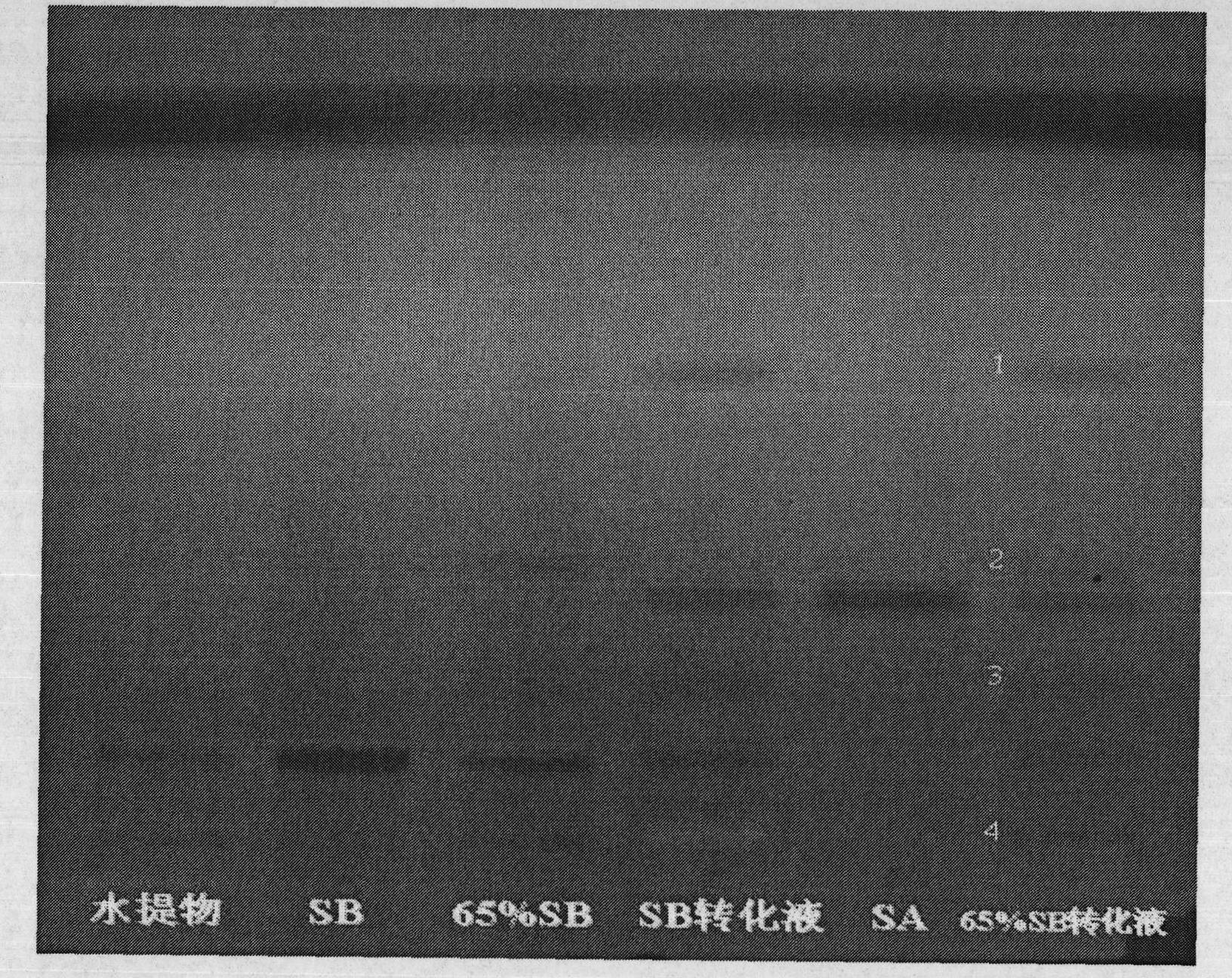

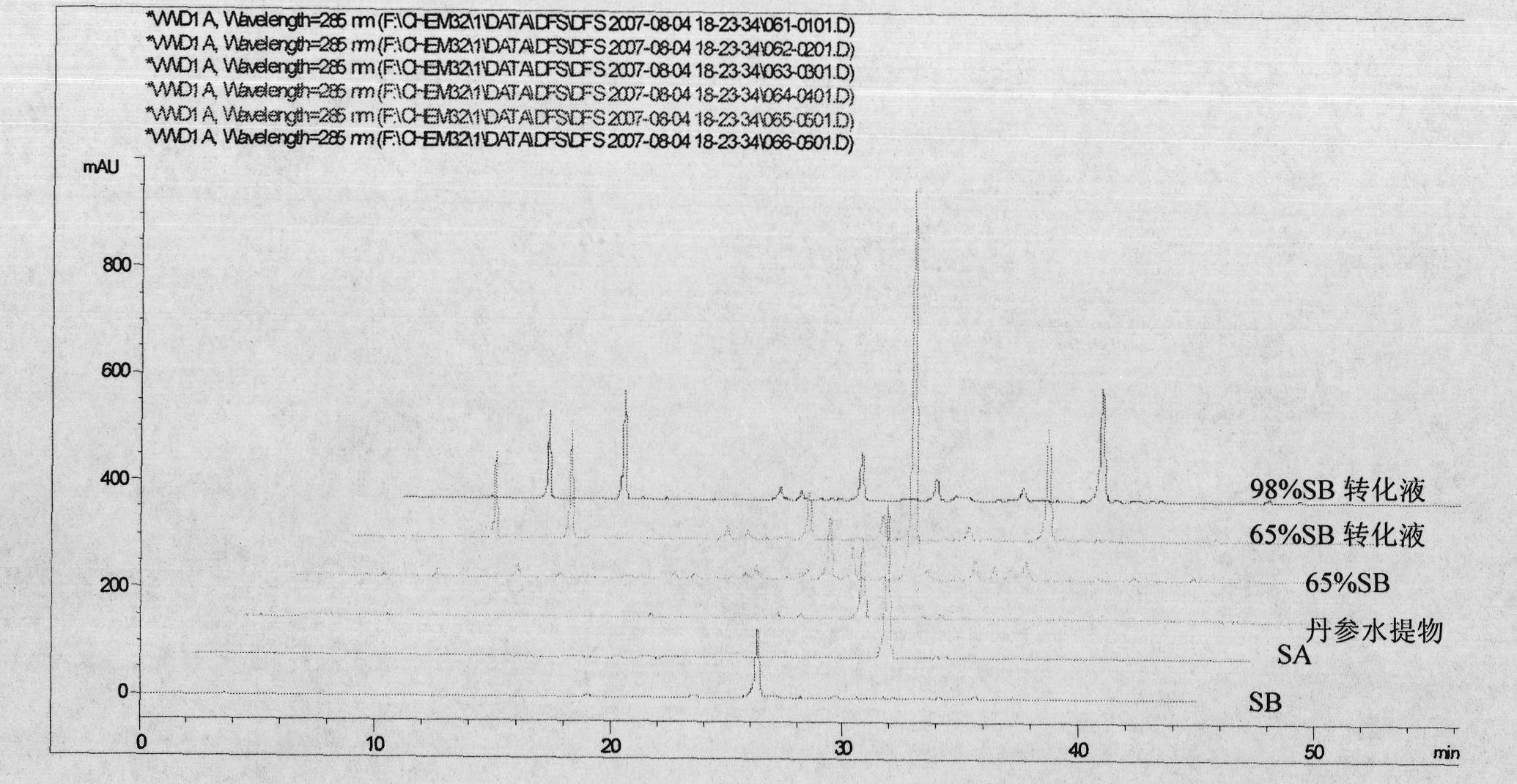

[0054] 1. Preliminary purification of salvianolic acid A by macroporous resin frontier chromatography and macroporous resin displacement chromatography;

[0055] 2. Further purification of salvianolic acid A by reverse phase chromatography;

[0056] 3. Purified salvianolic acid A by normal phase chromatography.

[0057] The filler of frontier chromatography described in step 1 is selected from macroporous adsorption resin ADS-5, D101 or DM130, the filler of described displacement chromatography is selected from macroporous adsorption resin ADS-8 or HPD100, the filler of frontier chromatography and the filler weight of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com