Substrate for flexible luminescent device and preparation method thereof

A technology for light-emitting devices and substrates, which is used in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., and can solve the problems of poor surface flatness of thin-layer carbon nanotubes, poor bonding force between carbon nanotubes and flexible substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

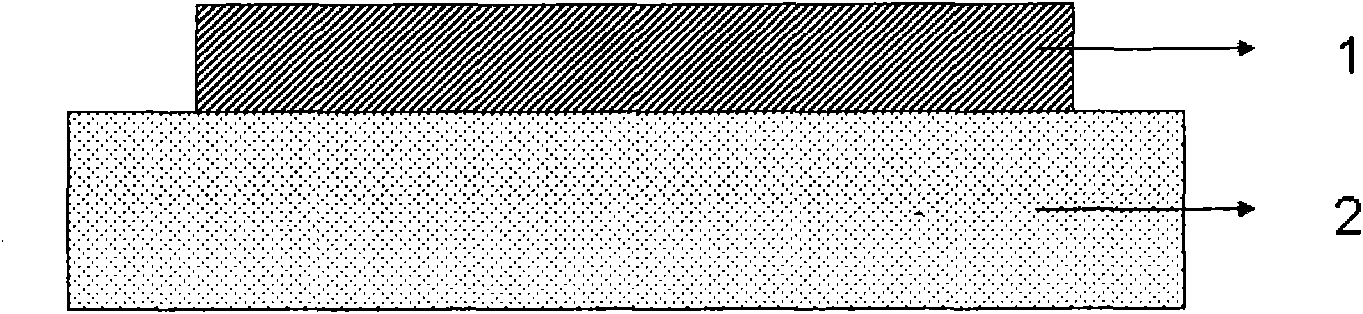

[0099] Such as figure 1 In the substrate structure shown, the flexible substrate 1 uses an adhesive that requires double curing, and the conductive layer 2 uses carbon nanotubes, the gaps of the carbon nanotube layer are filled with organic light-emitting materials, and the thickness of the carbon nanotube layer is 70nm.

[0100] The preparation method is as follows:

[0101] ① Clean the glass substrate with surface roughness less than 1nm, and dry it with dry nitrogen after cleaning;

[0102] ② Evenly disperse carbon nanotubes in a solvent, and prepare a carbon nanotube layer on a clean substrate by spin coating. The rotation speed of spin coating is 4000 rpm, the duration is 60 seconds, and the film thickness is about 70 nanometers;

[0103] ③ Drop-coat the solution containing organic light-emitting materials on the carbon nanotube layer, place the glass substrate in an environment of 80°C for 30 minutes, remove the remaining solvent in the carbon nanotube layer, and then s...

Embodiment 2

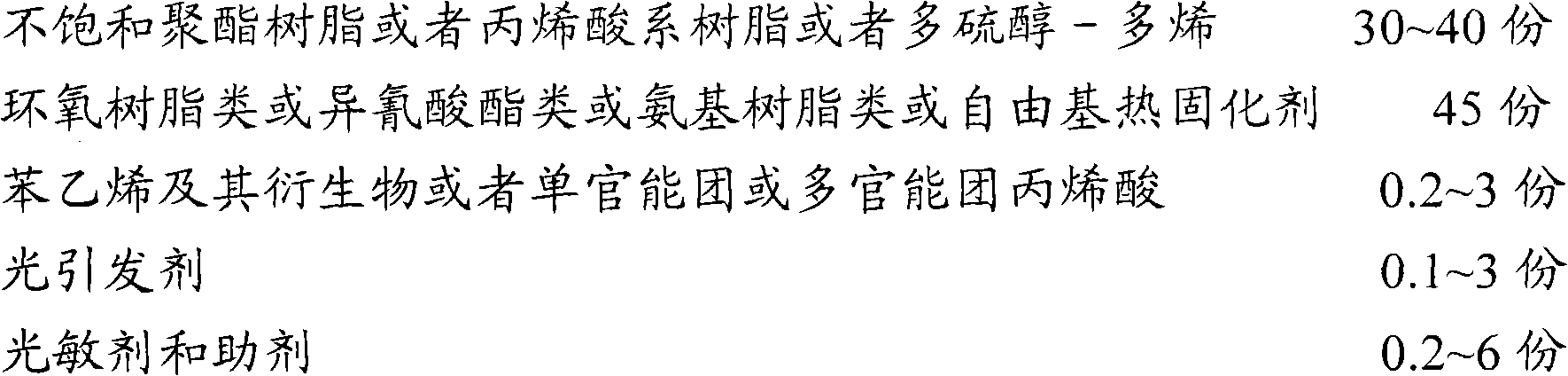

[0111] Such as figure 1 As shown in the substrate structure, the flexible substrate 1 adopts an adhesive that requires double curing, the conductive layer 2 adopts carbon nanotubes, the gaps of the carbon nanotube layer are filled with organic light-emitting materials, and the thickness of the carbon nanotube layer is 60 nm. The adhesive raw materials include the following components:

[0112]

[0113] The preparation method is similar to Example 1.

Embodiment 3

[0115] Such as figure 1 As shown in the substrate structure, the flexible substrate 1 adopts an adhesive that requires double curing, the conductive layer 2 adopts carbon nanotubes, and the gaps of the carbon nanotube layer are filled with organic light-emitting materials, and the thickness of the carbon nanotube layer is 50 nm. The adhesive raw materials include the following components:

[0116]

[0117] The preparation method is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com