Salt, alkali and calcium combined cycle production technology by the use of well mineral salt

A technology of combined cycle and mine salt, which is applied in the direction of carbonate preparations, alkali metal chlorides, calcium/strontium/barium halides, etc., can solve problems such as low mining efficiency, waste of resources, and difficulty in industrialized production. Achieve the effect of maximizing comprehensive utilization, reducing waste discharge, and suppressing geological disasters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

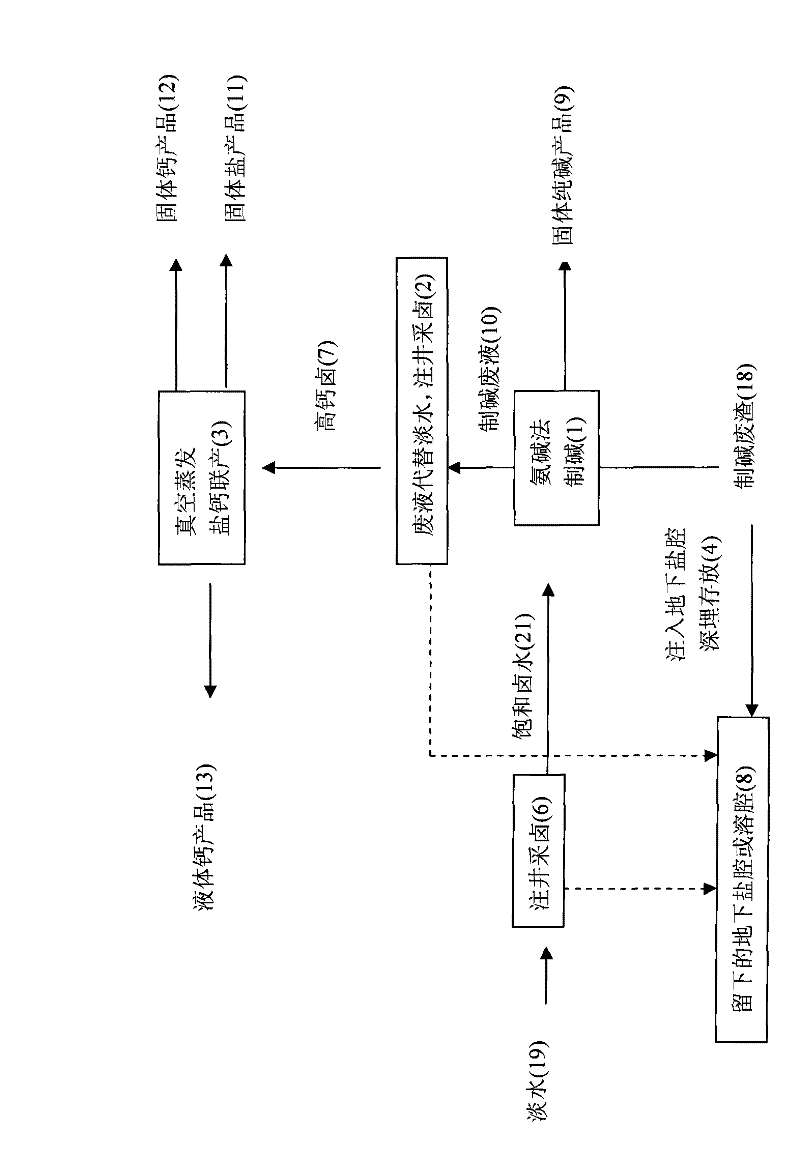

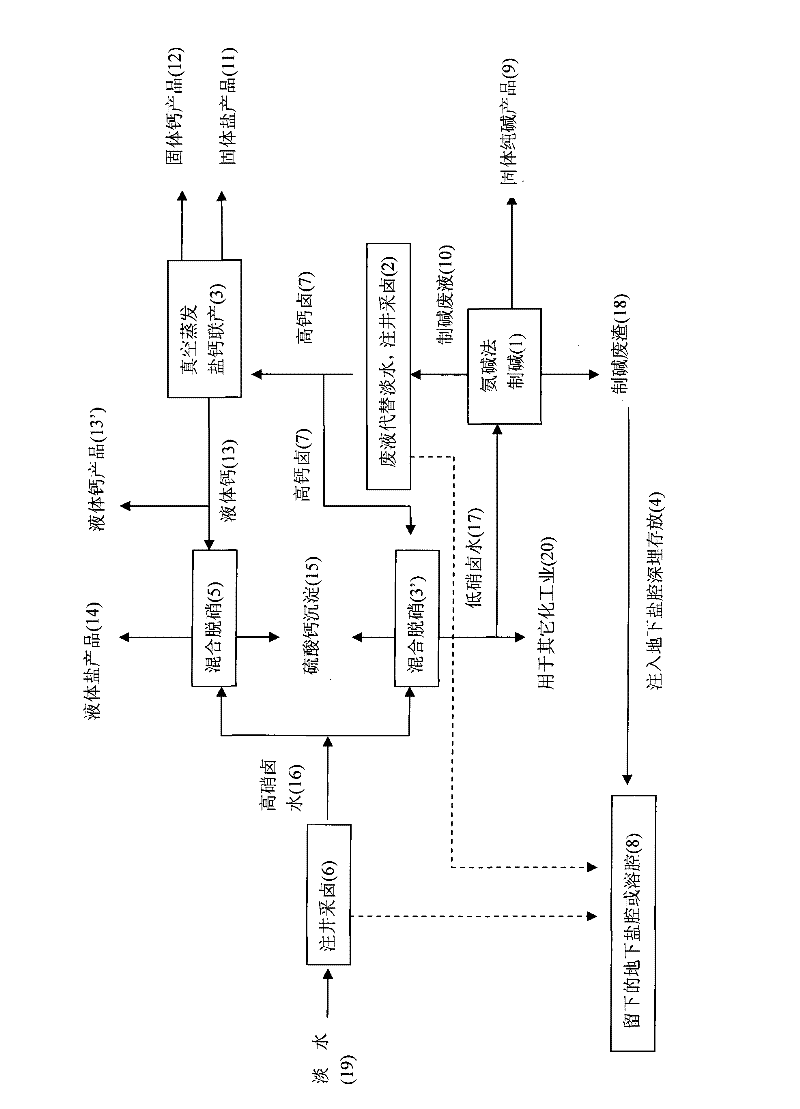

[0062] According to a second embodiment of the present invention, there is provided:

[0063] 7. A combined cycle production process utilizing salt, alkali and optional calcium products of calcium sulphate type mine salt, which comprises the following steps:

[0064] 1), utilize ammonia soda method to prepare alkali (Na 2 CO 3 ), obtain solid sodium carbonate, produce ammonia-soda waste liquid and ammonia-soda waste residue simultaneously,

[0065] 2) The waste liquid from the above steps replaces fresh water and is injected into the calcium sulfate type salt mine to mine brine to obtain high-calcium brine, and at the same time, a salt cavity is left underground.

[0066] 3), the high-calcium brine of the above step 2) is vacuum evaporated, resulting in crystallization, obtaining solid sodium chloride and calcium chloride dihydrate, and optional liquid calcium products,

[0067] 4), inject the waste residue produced in the above step 1) into the underground salt cavity form...

Embodiment 1

[0085] Explanation: It is sodium sulfate type well mine salt. In this embodiment, the production of liquid calcium and liquid salt products, and other uses of low-nitrate brine are not considered.

[0086] Alkali production from brine (Na 2 CO 3 ), that is: use brine (salt water), limestone (calcined to generate quicklime and carbon dioxide), and ammonia as raw materials to produce soda ash. First pass ammonia gas into saturated brine to form ammonia brine, then pass through carbon dioxide to generate sodium bicarbonate precipitate and ammonium chloride solution with low solubility; then filter and wash NaHCO 3 Tiny crystals are heated and calcined to produce soda ash products, and the carbon dioxide gas released during the process can be recycled and recycled; then the filtrate containing ammonium chloride is mixed with milk of lime [Ca(OH)2] and heated, and the released ammonia gas can be recycled recycle. Prepare alkali with 5L of low-nitrate brine and other raw material...

Embodiment 2

[0093] Explanation: It is a sodium sulfate type well mine salt. In this embodiment, it is considered to produce liquid calcium, liquid salt products, and other uses of low-nitrate brine.

[0094] Alkali production from brine (Na 2 CO 3 ), that is: use brine (salt water), limestone (calcined to generate quicklime and carbon dioxide), and ammonia as raw materials to produce soda ash. First pass ammonia gas into saturated brine to form ammonia brine, then pass through carbon dioxide to generate sodium bicarbonate precipitate and ammonium chloride solution with low solubility; then filter and wash NaHCO 3 Tiny crystals are heated and calcined to produce soda ash products, and the carbon dioxide gas released during the process can be recycled and recycled; then the filtrate containing ammonium chloride is mixed with milk of lime [Ca(OH)2] and heated, and the released ammonia gas can be recycled recycle. Prepare alkali with 5L of low-nitrate brine and other raw materials are suff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com