High-dispersing nanometer silver and high-performance conductive adhesive

A high-dispersion, nano-silver technology, applied in the direction of conductive adhesives, non-polymer adhesive additives, dyeing polymer organic compounds, etc., can solve the problems of backwardness and late start of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

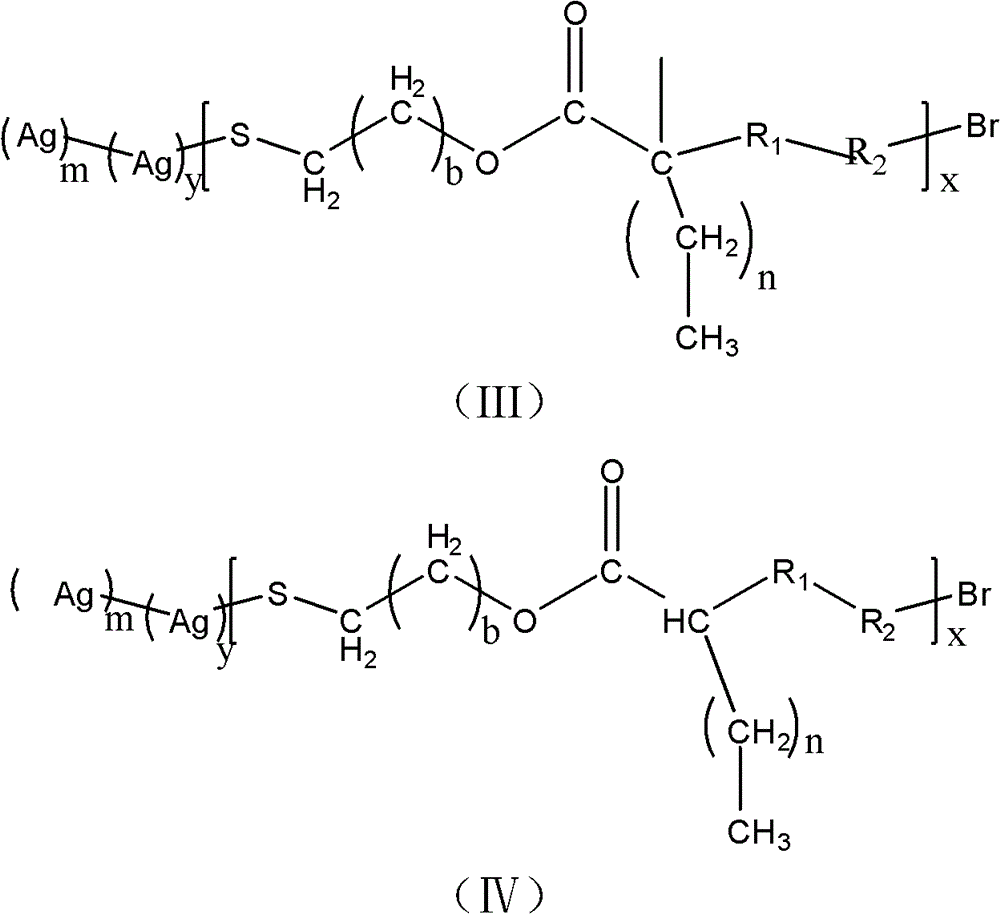

Method used

Image

Examples

Embodiment 1

[0083] 1. Preparation of highly dispersed granular nano silver

[0084] (1) Under anhydrous and oxygen-free conditions, add mercaptoethanol to 20ml of chloroform and triethylamine, and add dibromoisobutyryl bromide under stirring at 25°C, wherein triethylamine, dibromoisobutyryl bromide The molar ratio of bromine to mercaptoethanol was 2:2:1, stirred and reacted at 0°C for 24 hours, then added 20ml of water, then extracted the product of the reaction with toluene, and then washed the product with saturated ammonium chloride solution 4 Once again, dry with anhydrous sodium sulfate, and then vacuum dry to obtain ATRP initiator A containing mercapto groups.

[0085] (2) Control the reaction temperature to be 25°C, then slowly add the silver nitrate aqueous solution to the hydrazine hydrate solution, the silver nitrate drop rate is: 0.5ml / min, the stirring speed of the reaction system is 800rpm, after the silver nitrate dropwise , ATRP initiator A was immediately added to the rea...

Embodiment 2

[0103] 1. Preparation of highly dispersed linear nano-silver

[0104] (1) Under anhydrous and oxygen-free conditions, add mercaptododecanol to 20ml of dichloromethane and triethylamine, and add dibromoisovaleryl bromide under stirring at 15°C, wherein triethylamine, dibromoisovaleryl bromide The molar ratio of valeryl bromide to mercaptododecanol is 1.5:2:1, stirred and reacted at 8°C for 16 hours, then added 20ml of water, extracted the reaction product with toluene, and then used saturated ammonium chloride The product was washed with the solution for 4 times, then dried with anhydrous magnesium sulfate, and then vacuum-dried to obtain ATRP initiator B containing mercapto groups.

[0105](2) Get 20mL of silver nitrate propylene glycol solution with a molar concentration of 0.22mol / L, slowly add it to 20mL of propylene glycol solution containing 1.2g polyvinylpyrrolidone and 0.1g sodium chloride, the rate of addition is 1mL / min, and the stirring speed is 1000rpm, the reactio...

Embodiment 3

[0121] 1. Preparation of highly dispersed rod-shaped silver nanoparticles

[0122] (1) Under anhydrous and oxygen-free conditions, add mercaptooctaol to 20ml of toluene and amphetamine, and add 2-bromopropionyl bromide under stirring at 35°C, wherein amphetamine, 2-bromopropionyl bromide The molar ratio with mercaptooctaol is 1:2.5:1, stirred and reacted at 16°C for 8 hours, then added 20ml of water, extracted the reaction product with toluene, and washed the product 4 with saturated ammonium chloride solution Once again, dry it with anhydrous magnesium sulfate, and then vacuum-dry it to obtain ATRP initiator C containing mercapto groups.

[0123] (2) get 20mL molar concentration and be the silver nitrate propylene glycol solution of 0.22mol / L, slowly join in 20mL the propylene glycol solution that contains 12g polyvinylpyrrolidone and 0.1g sodium sulfide, the rate of addition is 1mL / min, and stirring speed is 1000rpm, The reaction temperature was 180°C. After the silver nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com