Method for dyeing wool/polyester fabrics

A dyeing method and fabric technology, which is applied in the field of wool and polyester fabric dyeing, can solve the problems of wool damage, low dyeing temperature, and light polyester color, and achieve the effects of reducing the use of additives, good color stability, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Dark dyeing of cationic modified polyester and shrink-resistant wool interwoven fabric

[0030] The disperse cationic dye used is a mixture of the following dyes (Nippon Kayaku):

[0031] KAYACRYL YELLOW GL-ED 0.5%

[0032] KAYACRYL RED GL-ED 0.65%

[0033] KAYACRYL BLACK MG-ED 3.8%

[0034] The reactive dyes used for wool are a mixture of the following dyes (Hunsman):

[0035] LANASOL RED CE 0.05%

[0036] LANASOL BLACK CE-R 1.3%

[0037] The auxiliary agents adopted are as follows:

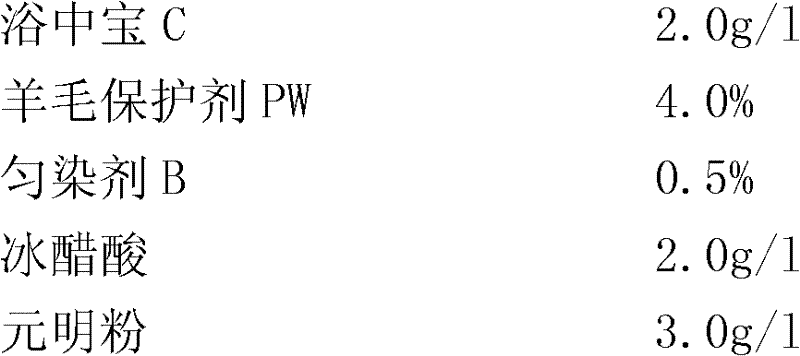

[0038]

[0039] The post-treatment additives used are as follows:

[0040] Soaping agent KFS (Nippon Kayaku) 2.0g / l

[0041] Ammonia 1.0%

[0042] Dyeing with 1.0% glacial acetic acid: Put the above-mentioned fabrics that have been fully degreased in advance in a high-temperature and high-pressure jet dyeing machine, add water to the specified amount, run at room temperature for 3-5 minutes, add 2.0g / l Yuzhongbao C, 4.0% wool protection agent PW, 0.5% leveling agent...

Embodiment 2

[0044] Example 2: Light-color dyeing of cationic modified polyester and shrink-proof wool interwoven fabric

[0045] The disperse cationic dye used is a mixture of the following dyes (Nippon Kayaku):

[0046] KAYACRYL YELLOW 3RL-ED 0.073%

[0047] KAYACRYL RED GL-ED 0.0525%

[0048] KAYACRYL BLUE GTL-ED 0.24%

[0049] The reactive dyes used for wool are a mixture of the following dyes (Hunsman):

[0050] LANASOL YELLOW 4G 0.014%

[0051] LANASOL RED 6G 0.025%

[0052] LANASOL BLUE 3G 0.026%

[0053] The auxiliary agents adopted are as follows:

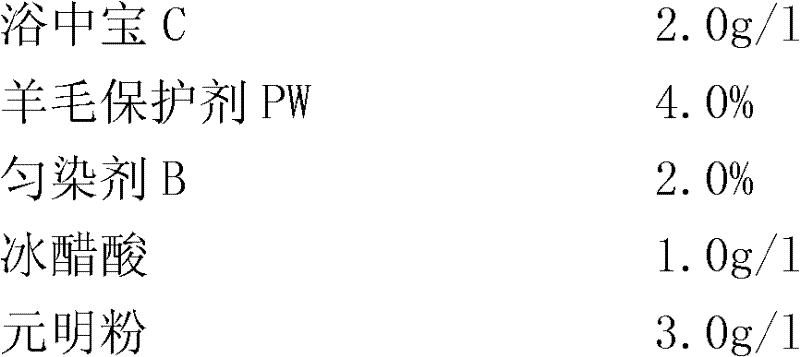

[0054]

[0055] The post-treatment additives used are as follows:

[0056] Soaping agent KFS (Nippon Kayaku) 1.0g / l

[0057] Dyeing: Put the above-mentioned fabrics that have been fully degreased in advance into a high-temperature and high-pressure jet dyeing machine, add water to the specified amount, run at room temperature for 3-5 minutes, add 2.0g / l Yuzhongbao C, 4.0% wool protection agent PW, 2.0% Leveling agent B, 0.5...

Embodiment 3

[0059] Embodiment 3 Carry out the detection of color fastness with the dark fabric that embodiment 1 obtains

[0060] The color fastness test data are shown in Table 1:

[0061] Table 1

[0062] Washing fastness

[0063] (Note: The conventional dark-colored fabric mentioned here refers to the interwoven fabric of polyester and shrink-proof wool obtained through the prior art)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com