Electroless metal coatings

An electroless nickel plating and coating technology, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problems of electroless nickel plating coating strain tolerance corrosion resistance, product corrosion, shortened service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

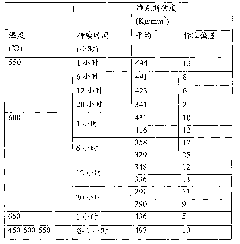

Embodiment 1

[0038] The surface-prepared samples are preheated and fixed to a fixture, followed by immersion in an electroless plating solution. The pH of the electroless plating solution was monitored with a sensitive pH strip ranging from pH 5 to pH 8 and maintained at about pH 7 by the dropwise addition of lactic acid solution. Take care to avoid the presence of any sodium hydroxide to prevent the formation of a nickel hydroxide precipitate. At the beginning of the plating step, the sample was rotated at about 4 rpm while submerged. Blistering appeared at the end of 30 seconds, indicating the start of plating. Allow the sample to rotate at a constant speed in the electroless plating solution. At a temperature of about 85°C, at a pH of about 5.9, the plating rate was maintained at about 0.75 mil / hr for about 2.5 hours. The thickness of the applied coating is monitored with a witness coupon (typically a blade or dip pan) and measured with a micrometer. Once the desired coating thickne...

Embodiment 2

[0053] Surface prepared samples (impeller assemblies made from Al82F22 low alloy steel) were coated with the electroless nickel coating composition as described above in Example 1 . The surface-prepared samples were preheated and fixed to a fixture before being immersed in an electroless plating solution. The pH of the electroless plating solution was monitored with a sensitive pH strip ranging from pH 5 to pH 8 and maintained at about pH 7 by the dropwise addition of lactic acid solution. Take care to avoid the presence of any sodium hydroxide to prevent the formation of a nickel hydroxide precipitate. At the beginning of the plating step, the sample was rotated at about 4 rpm while submerged. Blistering appeared at the end of 30 seconds, indicating the start of plating. Allow the sample to rotate at a continuous speed in the electroless plating solution. At a temperature of about 85°C, at a pH of about 5.9, the plating rate was maintained at about 0.325 mil / hr for about 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com