New high-resistance electrical heating alloy material and preparation method thereof

An electrothermal alloy and high-resistance technology, applied to high-resistivity electrothermal alloy materials, Cr20Ni80Zr materials, new high-resistance electrothermal alloy materials and their preparation fields, can solve the problem that the mechanical performance requirements of industrial electrothermal elements cannot be met, and the service life can only reach 2000 hours, affecting the service life of the finished product, etc., to achieve the effect of excellent anti-oxidation performance, reasonable component design, and ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is further described and understood by non-limiting examples below.

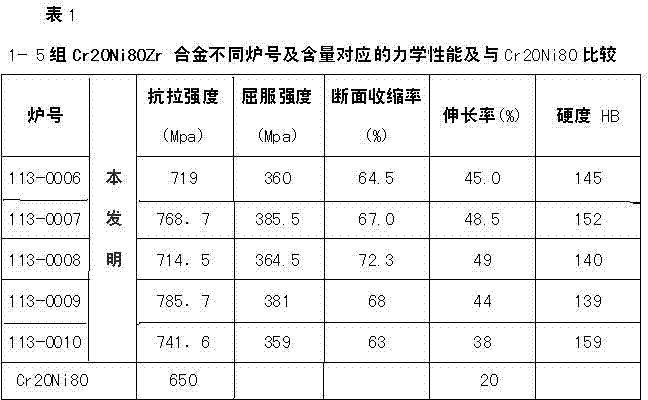

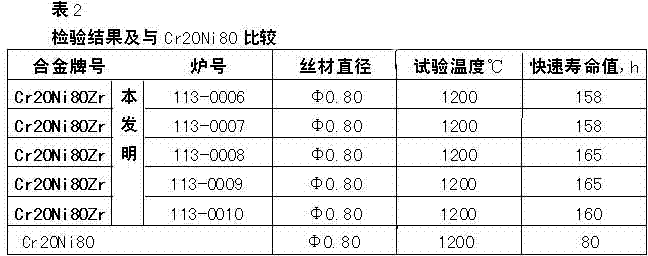

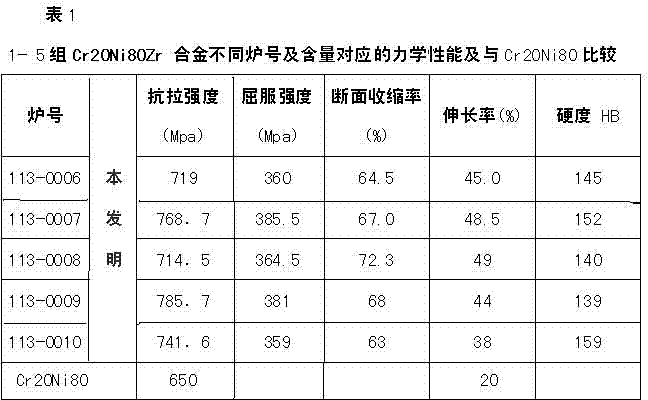

[0050] A new type of high-resistance electrothermal alloy material of the present invention has prepared 5 sets of examples, and the furnace numbers are: 113-0006, 0007, 0008, 0009, and 0010. The composition and content of the new high-resistance electric heating alloy material of embodiment 1-5 are calculated by weight %, as follows:

[0051] The first group: furnace number: 113-0006 C:0.04%; Si:1.35%; Mn:0.20%; P:0.010%; S:0.006%; Cr:22.5%; Ni:75.0%; Al:0.20%; Fe: 0.2%; Ti: 0.10%; Zr: 0.50%; RE: 0.30%.

[0052] The second group: furnace number: 113-0007 C:0.03%; Si:1.20%; Mn:0.30%; P:0.008%; S:0.005%; Cr:22.0%; Ni:75.0%; Al:0.22%; Fe: 0.3%; Ti: 0.10%; Zr: 0.45%; RE: 0.25%.

[0053] The third group: furnace number: 113-0008 C:0.05%; Si:1.25%; Mn:0.25%; P:0.008%; S:0.004%; Cr:21.5%; Ni:75.5%; Al:0.15%; Fe: 0.5%; Ti: 0.10%; Zr: 0.30%; RE: 0.20%.

[0054] The fourth group: fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com