Superconductive liquid for heat exchange device and preparation method thereof

A heat exchange device and superconducting liquid technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as accidents, poor use safety, high cost of superconducting liquid, etc., and achieve cheap raw materials and safe use Stable, effective formula composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Every 100 kg of superconducting liquid contains: 25 kg of calcium chloride, 0.1 kg of triethanolamine, 0.1 kg of dimethyl silicone oil, 0.05 kg of benzotriazole, 0.1 kg of 101 descaling and preservative, 0.65 kg of sodium silicate, and 74 kg of tap water. Kilogram.

[0013] 101 descaling and preservatives are produced and sold by Shanghai Yuzhen Water Treatment Technology Co., Ltd.

[0014] Preparation method: Take calcium chloride, triethanolamine, dimethyl silicone oil, benzotriazole, 101 descaling and preservative, sodium silicate according to the above formula, first dissolve the calcium chloride with 80% of the amount of tap water in the formula, Calcium chloride solution is obtained; 20% of tap water in the formula is used to dissolve benzotriazole, then sodium silicate, 101 descaling antiseptic, triethanolamine are added and dissolved successively, and the gained solution is combined with the calcium chloride solution. Add simethicone and stir well.

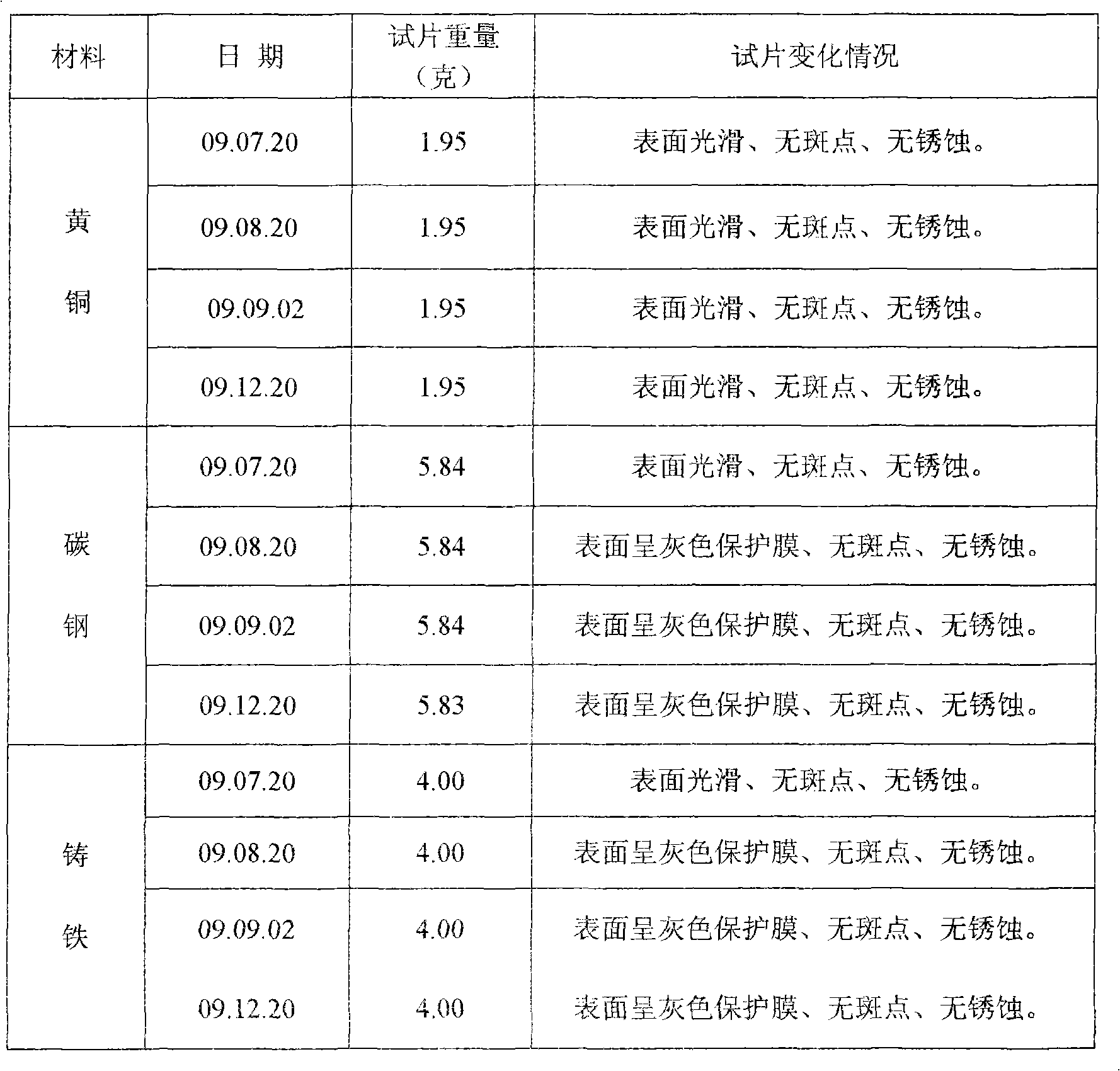

[0015] Ch...

Embodiment 2

[0017] Every 100 kg of superconducting liquid contains: 30 kg of calcium chloride, 0.11 kg of triethanolamine, 0.1 kg of dimethyl silicone oil, 0.06 kg of benzotriazole, 0.11 kg of 101 descaling and preservative, 0.65 kg of sodium silicate, and 68.97 kg of tap water Kilogram.

[0018] The preparation method is the same as in Example 1.

[0019] Each teaching building of Liujia Town Central Primary School in Yushu City is 600m 2 , using 0.3 tons of coal-fired boilers for heating. From 2007 to now, the above-mentioned superconducting liquid of our company has been used. The same heating standard requires 20 tons of raw coal for each heating period before use. After using superconducting liquid, each heating In the period, each building only needs 15.6 tons of raw coal. Each heating period saves 22% of raw coal.

Embodiment 3

[0021] Every 100 kg of superconducting liquid contains: 35 kg of calcium chloride, 0.12 kg of triethanolamine, 0.1 kg of dimethyl silicone oil, 0.07 kg of methyl benzotriazole, 0.12 kg of 101 descaling and preservative, 0.65 kg of sodium silicate, 63.94 kg of tap water.

[0022] The preparation method is the same as in Example 1.

[0023] Yushu Jifu Rice Industry Co., Ltd. Office Building 300m 2 , with a 0.1 ton coal-fired boiler for heating. The above-mentioned superconducting liquid of our company has been used since 2007. The same heating standard requires 9 tons of raw coal for each heating period before use. After using the superconducting liquid, each heating period is The building only needs 6.5 tons of raw coal. Each heating period saves 27% of raw coal.

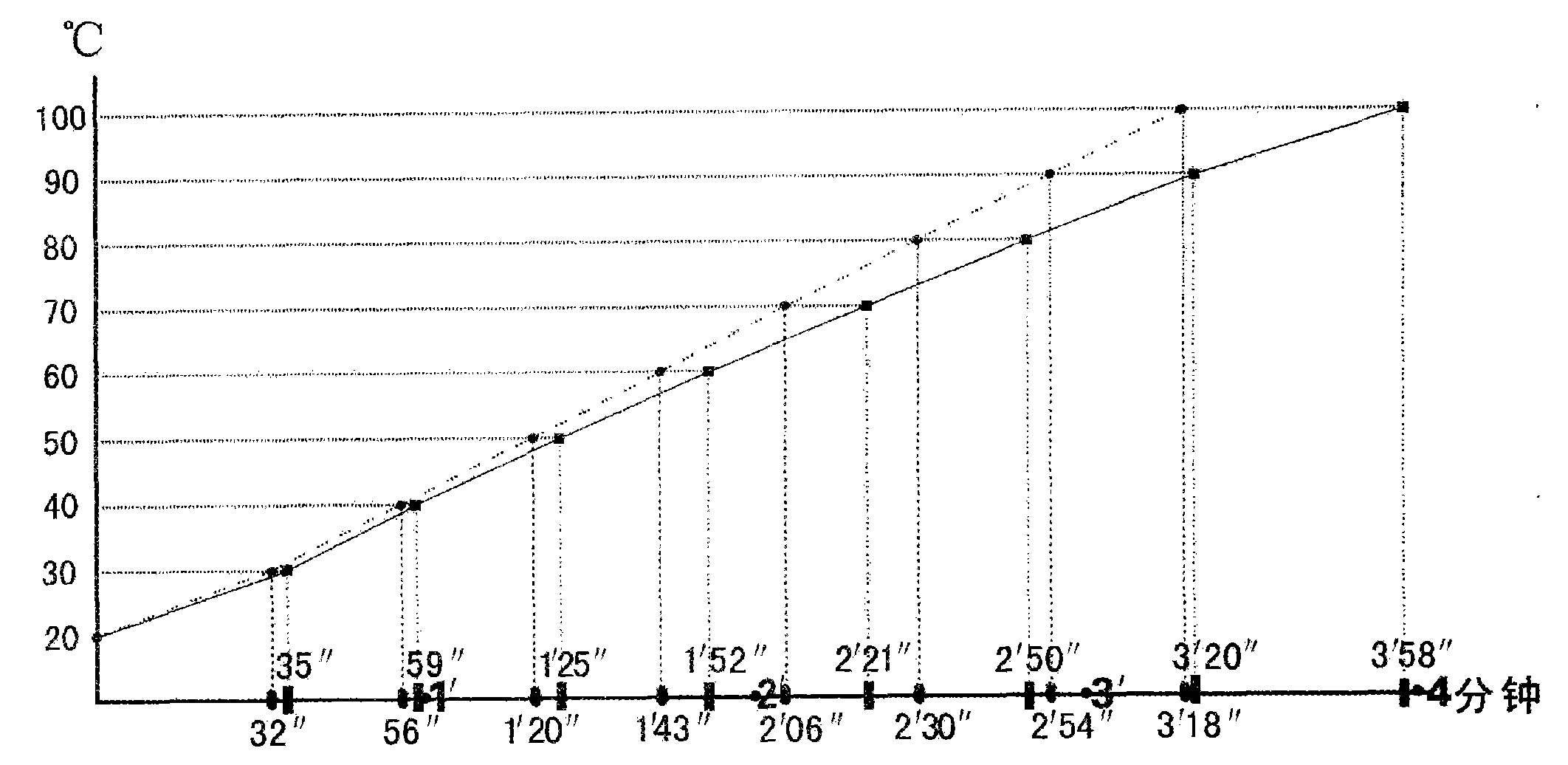

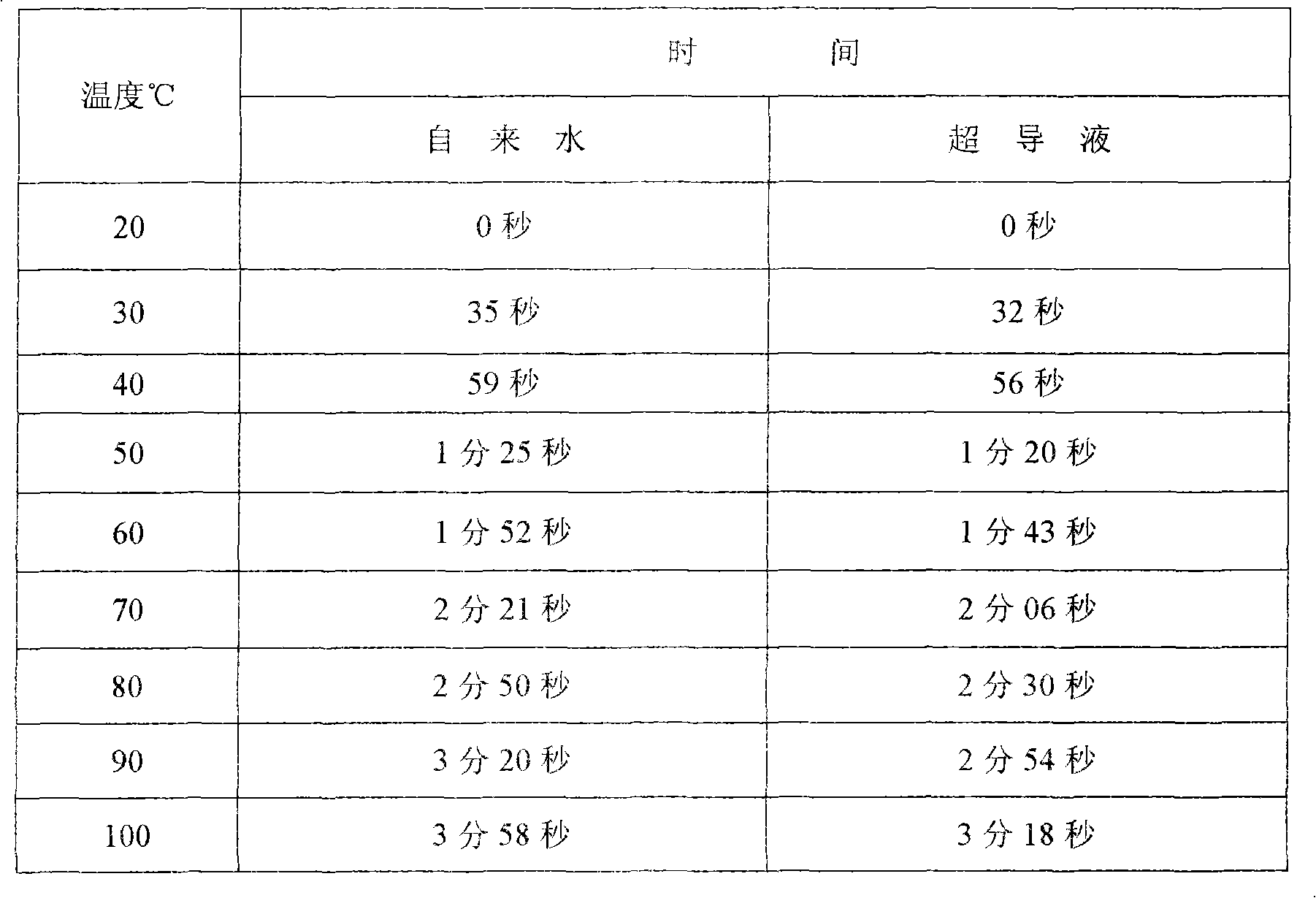

[0024] Comparative experiment example of tap water and superconducting liquid heating

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com