Method for preparing high-purity quercetagetin

A high-purity quercetin-tagoldin technology, applied in organic chemistry and other fields, can solve problems such as high production cost, low recovery rate, and complicated steps, and achieve the effects of low sample loss, high recovery rate, and large separation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

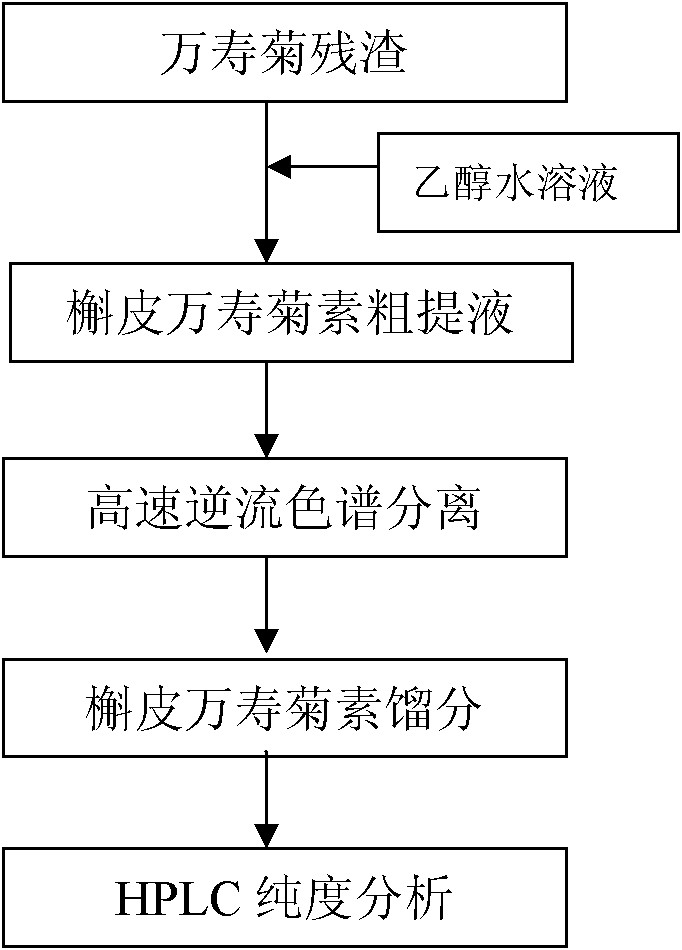

Method used

Image

Examples

Embodiment 1

[0022] It is separated by a high-speed countercurrent chromatographic system with a column volume of 300ml (equipped with TBP-5002 constant current and constant pressure pump, HD-3 ultraviolet detector), and chloroform, n-butanol and water are selected as the solvent system, according to the volume ratio of 4:3:3 Put the above solvent components in a separatory funnel, shake well and let stand to separate layers. After equilibrating for a certain period of time, separate the upper phase (stationary phase) and the lower phase (mobile phase).

[0023] Put 30 g of fermented marigold lutein lipid extraction residue in 300 mL of 5% ethanol aqueous solution, extract at 30° C. for 10 h, and filter to obtain a crude quercetin tagetin extract. Concentrate 30 g of the quercetin-tagerin crude extract to a paste under reduced pressure, dissolve it in 30 ml of mobile phase, and obtain a solution containing quercetin-tagenate for use. Use the solution containing quercetin tagetin as the in...

Embodiment 2

[0025] A high-speed countercurrent chromatography system with a column volume of 1000ml was used for separation. Select n-hexane, ethanol and water as the solvent system, put the above-mentioned solvent components in a separatory funnel according to the volume ratio of 5:2:3, shake well and let stand to separate layers. After equilibrating for a certain period of time, separate the upper phase (stationary phase) and the lower phase (mobile phase).

[0026] Place 150 g of the fermented marigold lutein extract residue in 1500 mL of 50% ethanol aqueous solution, extract at 60° C. for 6 h, and filter to obtain a crude quercetin tagetin extract. Concentrate 100 g of the quercetin-tagerin crude extract under reduced pressure to a paste, dissolve it in 150 ml of mobile phase, and obtain a solution containing quercetin-tagenate for use. Use the solution containing quercetin tagetin as the injection sample. Before the injection, fill the entire column with the stationary phase, adjust...

Embodiment 3

[0028] A high-speed countercurrent chromatographic system with a column volume of 5000ml was used for separation. Ethyl acetate, methanol and water were selected as the solvent system, and the above solvent components were placed in a separatory funnel according to the volume ratio of 1:1:1, shaken evenly, and allowed to stand and separate into layers. After equilibrating for a certain period of time, separate the upper phase (stationary phase) and the lower phase (mobile phase).

[0029] Put 300 g of fermented marigold lutein extract residue in 3000 mL of 90% ethanol aqueous solution, extract at 90° C. for 0.5 h, and filter to obtain a crude quercetin tagetin extract. Concentrate 300g of quercetin-tagetine crude extract under reduced pressure to a paste, dissolve it in 300ml of mobile phase, and obtain a solution containing quercetin-tagagene for use. Use the solution containing quercetin tagetin as the injection sample. Before the injection, fill the entire column with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com