Processing method and anti-corrosion technology for magnetic refrigeration material

A technology of magnetic refrigeration materials and processing methods, applied in the direction of magnetic materials, manufacturing tools, other manufacturing equipment/tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

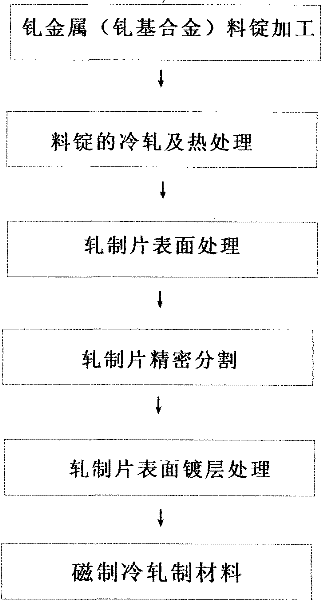

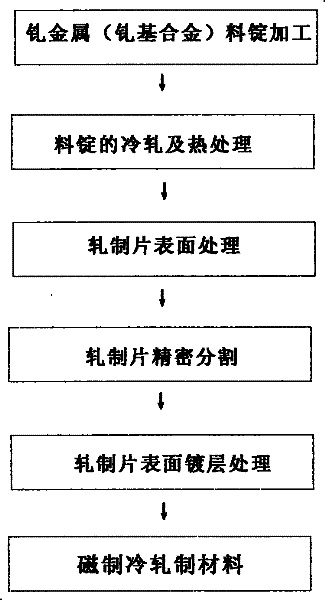

Method used

Image

Examples

Embodiment Construction

[0042] Rare earth magnetic refrigeration materials are non-polluting refrigeration materials. Using magnetic refrigeration materials to replace refrigerators, refrigerators, freezers and air conditioners currently using Freon refrigerants can eliminate environmental pollution caused by the production and use of Freon-based refrigeration and damage to the ozone layer. Magnetic refrigeration is based on the principle of magnetocaloric effect, using an external magnetic field to make the magnetic moment of the magnetic working medium change in an orderly and disorderly manner (phase transition), causing the magnet to absorb heat and release heat to perform a refrigeration cycle. Compared with gas compression refrigeration , Magnetic refrigeration has the characteristics of high entropy density, small size, simple structure, low noise, high efficiency and low power consumption. At present, magnetic refrigeration has been widely used in low temperature regions. At present, due to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com