Plate material and method for manufacturing a plate material

A plate and substrate technology, applied in applications, household appliances, ceramic products, etc., to achieve high thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] figure 1 A hob with a cover 26 made of sheet metal is shown schematically. This cover plate 26 has a coated upper side for placing cooking utensils and a back side (not shown), said upper side being smooth and easy to clean, near the back side an induction heating element 28 is arranged for heating the Cooking utensils on the cover plate 26. The cover plate 26 according to the invention is used in induction hobs with a typical basin level and in induction hobs of the matrix module or micromodule type with a large number of smaller inductors arranged in a grid. Furthermore, use in hobs with radiant heating is conceivable.

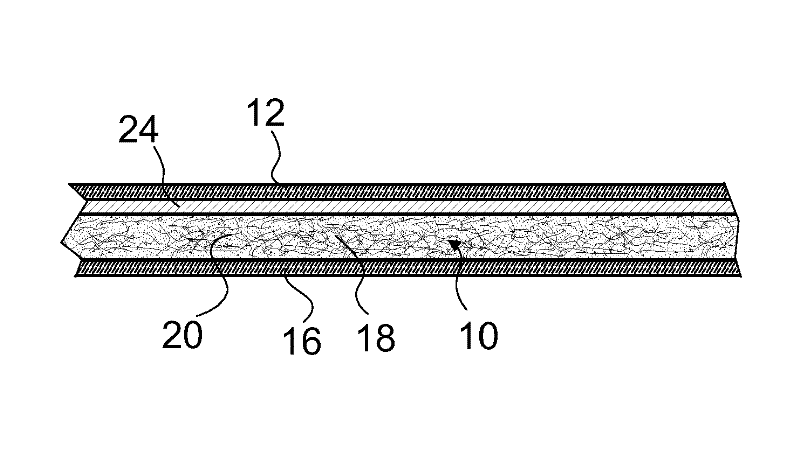

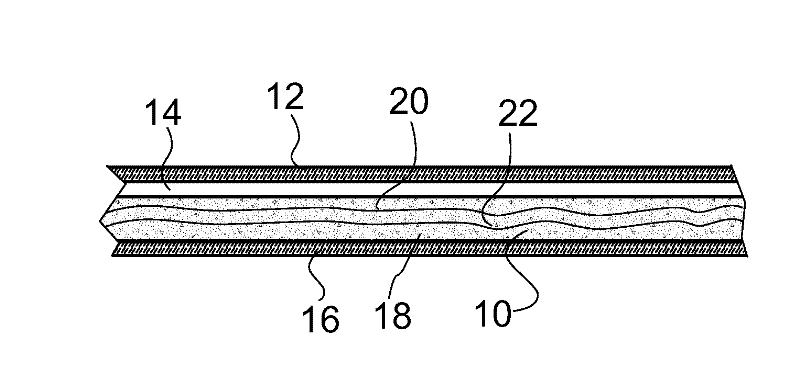

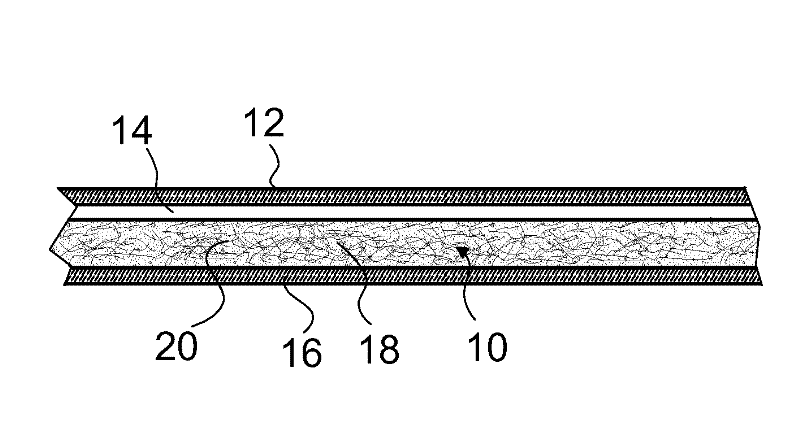

[0032] figure 2 shown in cross section figure 1 The plate material of the middle cover plate 26, which shows the layer structure of the plate material. The sheet includes a substrate 10 and a plurality of layers 12 , 14 , 16 . exist figure 2 The orientation shown in corresponds to the orientation of the cover plate 26 in the operating state. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com