Method for preparing titanium dioxide nanoparticle composite silver plating on surface of polyester fabric

A technology of nano-titanium dioxide and polyester fabric, applied in the field of surface modification of polyester fabric, which can solve the problems of non-photocatalytic degradation performance and thin silver coating of ordinary chemically silver-plated fabrics, so as to endow photocatalytic activity and improve wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

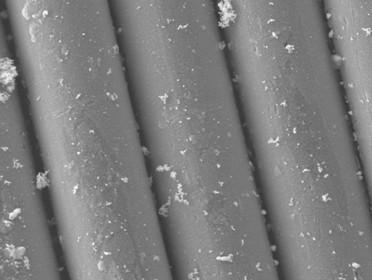

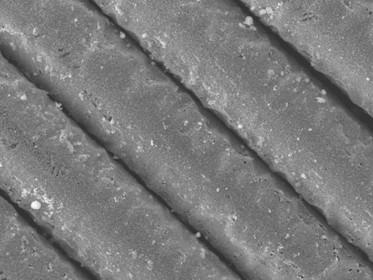

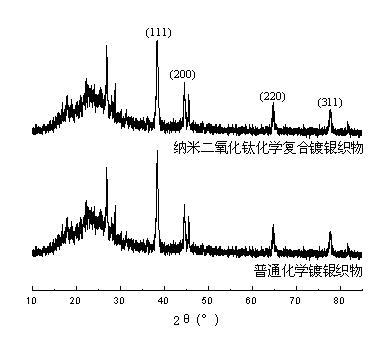

[0046] Pre-treatment of polyester fabric: use 160g / L sodium hydroxide to treat polyester fabric at 45°C for 45 minutes, and control the mass loss rate at about 8%; use 0.12g / L palladium chloride, 8g / L stannous chloride, 8g / L hydrochloric acid, 140g / L sodium chloride solution, treat polyester fabric at 45°C for 2 hours; treat polyester fabric with 80g / L hydrochloric acid at 30°C for 1min; use 10g / L sodium hypophosphite at room temperature Down treatment polyester fabric 2min. Preparation of nano-titanium dioxide dispersion: soak 10 g of nano-titanium dioxide particles in 1 liter of a mixed solution of hydrochloric acid and sulfuric acid with a volume ratio of 1:1, ultrasonically vibrate for 10 minutes at 50KHz and 100W, then neutralize with sodium hydroxide solution, and use Repeatedly wash with ionic water until the solution is neutral, vacuum filter, and dry at 80°C; disperse the cleaned nano-titanium dioxide particles in a mixed solution of 2g / L polyvinylpyrrolidone and Twee...

Embodiment 2

[0049] Pre-treatment of polyester fabric: use 240g / L sodium hydroxide to treat polyester fabric at 65°C for 70 minutes, and control the mass loss rate at about 16%; use 0.2g / L palladium chloride, 14g / L stannous chloride, 14g / L hydrochloric acid, 180g / L sodium chloride, treat polyester fabric at 65°C for 6 hours; use 120g / L hydrochloric acid, treat polyester fabric at 60°C for 5 minutes; use 20g / L sodium hypophosphite at room temperature Treat polyester fabric for 8 minutes. Preparation of nano-titanium dioxide dispersion: Soak 30g of nano-titanium dioxide particles in 1 liter of a mixed solution of hydrochloric acid and sulfuric acid with a volume ratio of 1:1, ultrasonically vibrate for 30 minutes at 50KHz and 100W, and then neutralize with 1 molar sodium hydroxide solution. Repeatedly wash with deionized water until the solution is neutral, vacuum filter, and dry at 80°C; disperse the cleaned nano-titanium dioxide particles in a mixed solution of 2 g / L polyvinylpyrrolidone a...

Embodiment 3

[0052]Pre-treatment of polyester fabric: use 200g / L sodium hydroxide to treat polyester fabric at 50°C for 60 minutes, and control the mass loss rate at about 12%; use 0.16g / L palladium chloride, 12g / L stannous chloride, Treat polyester fabric with 12g / L hydrochloric acid and 160g / L sodium chloride at 60°C for 5 hours; treat polyester fabric with 100g / L hydrochloric acid at 45°C for 2 minutes; treat with 15g / L sodium hypophosphite at room temperature Polyester fabric 5min. Preparation of nano-titanium dioxide dispersion: Soak 15g of nano-titanium dioxide particles in 1 liter of a mixed solution of hydrochloric acid and sulfuric acid with a volume ratio of 1:1, ultrasonically vibrate for 20 minutes at 50KHz and 100W, and then neutralize with 1 molar sodium hydroxide solution. Repeatedly wash with deionized water until the solution is neutral, vacuum filter, and dry at 80°C; disperse the cleaned nano-titanium dioxide particles in a mixed solution of 2 g / L polyvinylpyrrolidone an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com