Polycrystalline silicon ingot doping method and ingot casting equipment for implementing method

A technology of polysilicon and polysilicon blocks, which is applied in the growth of polycrystalline materials, chemical instruments and methods, crystal growth, etc., can solve economic losses, the doping weight of boron master alloy ingredients is prone to deviation, and it is difficult to evaluate the quality and performance of silicon materials, etc. problems, to achieve uniform overall performance and reduce economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

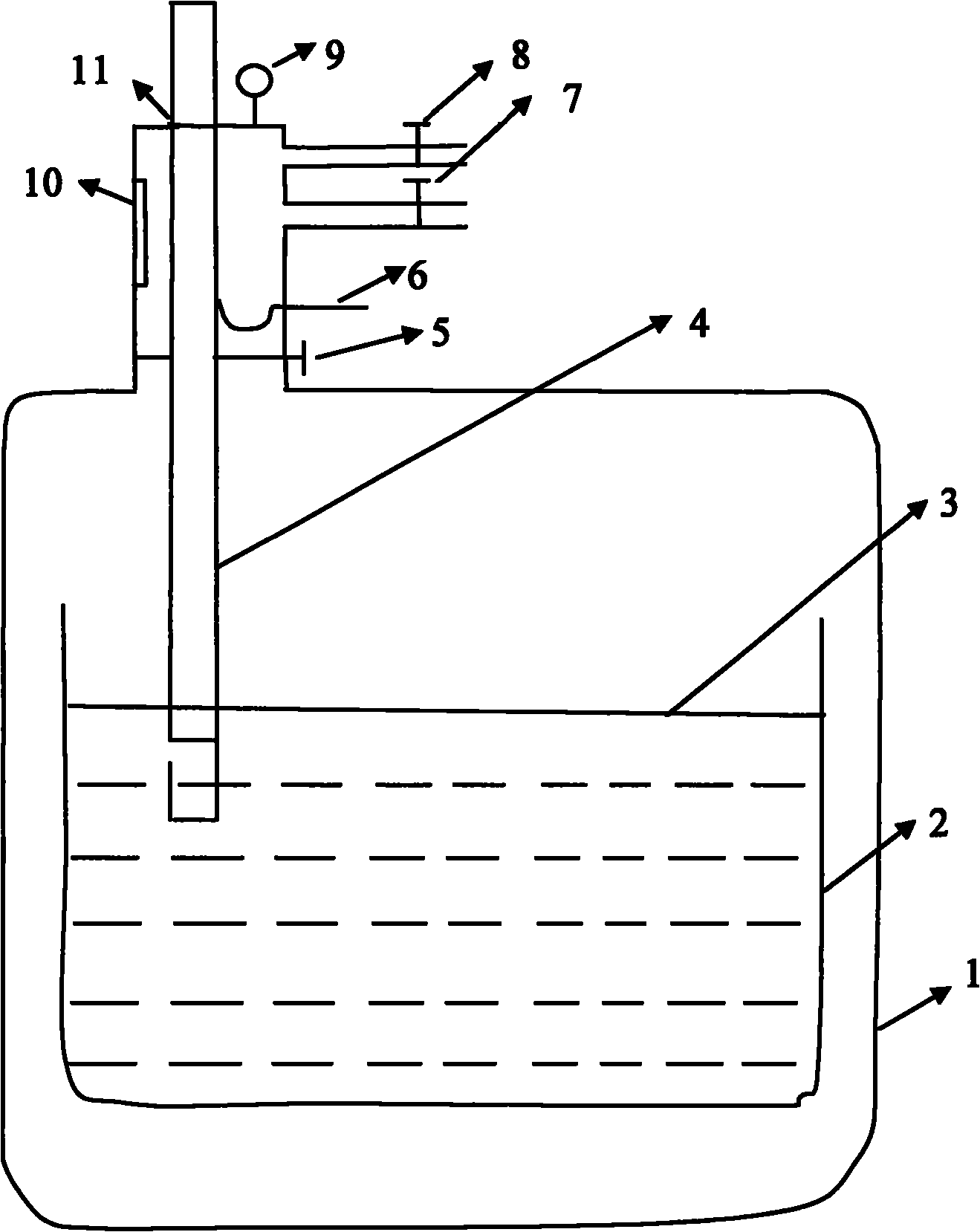

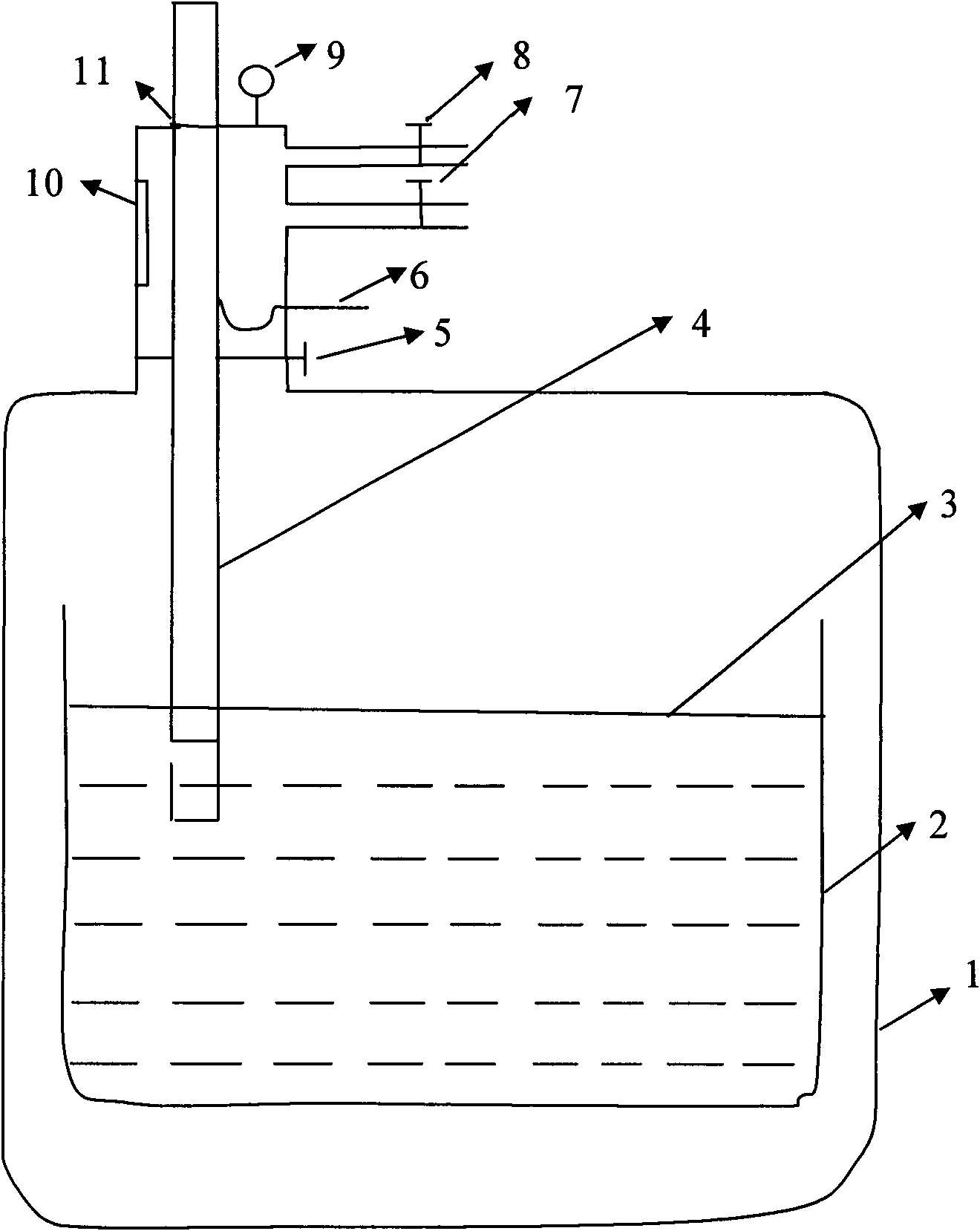

Image

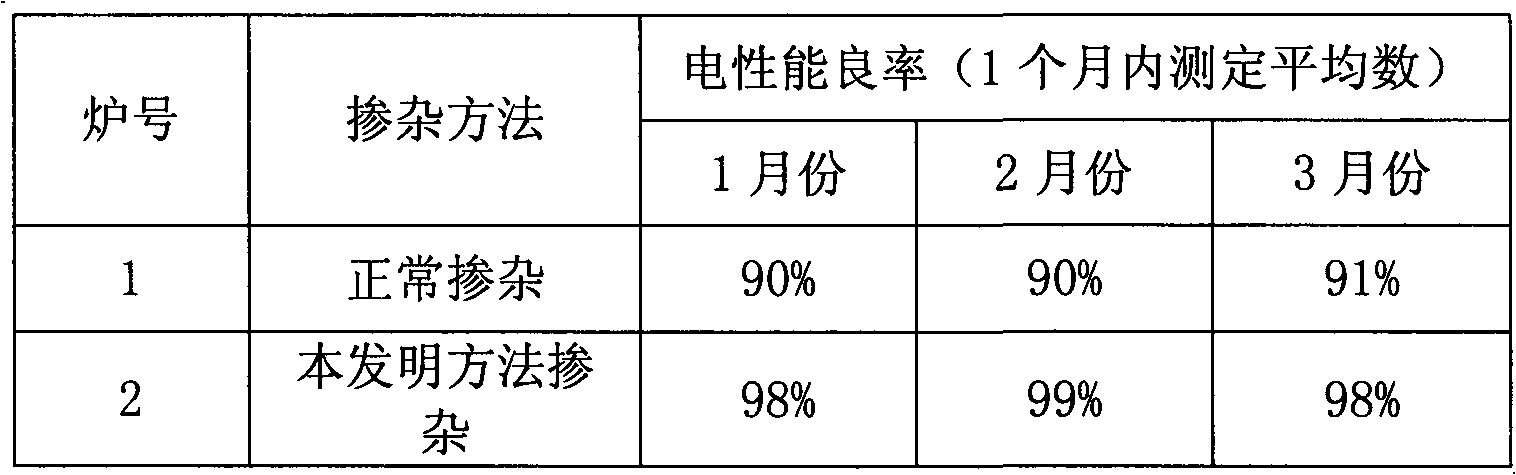

Examples

Embodiment

[0015] An embodiment, a method for doping a solar polysilicon ingot, comprising the following steps:

[0016] 1. No less than 50% of the original silicon material and its recycled miscellaneous materials: single crystal edge leather, single crystal head and tail material, single crystal crucible bottom material, polycrystalline edge leather, polycrystalline top and bottom material, and single, One or any of the miscellaneous materials such as polycrystalline silicon wafer waste is placed in the crucible, and the crucible is loaded into the ingot casting furnace.

[0017] 2. Raise the temperature of the ingot casting furnace. When the silicon material is completely melted, extract a part of the silicon liquid from the molten silicon liquid and solidify it into a polysilicon block. The conductivity type of the silicon block is measured, and the resistivity of the silicon block is measured with a four-probe resistance tester.

[0018] 3. Calculate the weight of the boron-doped m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com