Preparation method of glass fiber reinforced epoxy resin composite material modified by reclaimed circuit board powder

A technology of glass fiber and epoxy resin, which is applied in the field of preparation of circuit board recycled powder modified glass fiber reinforced epoxy resin composite materials, can solve the problems of low interface bonding strength, low surface energy, low reactivity, etc. Achieve the effect of increasing the interface bonding strength, improving the interface bonding performance, and broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

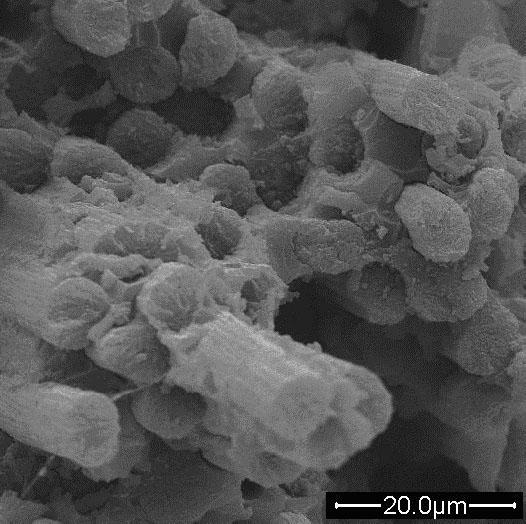

Image

Examples

Embodiment l

[0017] Example 1: Using glass fiber as the initial raw material, the glass fiber is modified by a silane coupling agent KH550 to obtain a surface-active glass fiber reinforcement; the surface of the dried circuit board recycled powder is subjected to active treatment, and then combined with double Phenol A-type epoxy resin (E-44) is mixed to obtain a modified epoxy resin matrix filled with recycled circuit board powder; finally, the glass fiber reinforcement modified by the coupling agent obtained above and recycled circuit board powder are filled The modified epoxy resin matrix is compounded in a certain way to obtain a glass fiber reinforced epoxy resin composite material modified by recycled circuit board powder.

[0018] Step (1): Weigh 200g of dry glass fiber, immerse the dry glass fiber in silane coupling agent KH550 at 30°C for 1 hour, take it out, and dry it at 60°C for 4 hours to obtain a surface-coated coupling agent Modified glass fiber reinforcement;

[0019] St...

Embodiment 2

[0024] Example 2: Using glass fiber as the initial raw material, the glass fiber is modified by the silane coupling agent KH570 to obtain a surface-active glass fiber reinforcement; the surface of the dried circuit board recycled powder is subjected to active treatment, and then combined with double Phenol A-type epoxy resin (E-51) is mixed to obtain a modified epoxy resin matrix filled with recycled circuit board powder; finally, the glass fiber reinforcement modified by the coupling agent obtained above and recycled circuit board powder are filled The modified epoxy resin matrix is compounded in a certain way to obtain a glass fiber reinforced epoxy resin composite material modified by recycled circuit board powder.

[0025] Step (1): Weigh 600g of dry glass fiber, immerse the dry glass fiber in silane coupling agent KH570 at 50°C for 2 hours, take it out, and dry it at 60°C for 2 hours to obtain a surface-coated coupling agent Modified glass fiber reinforcement;

[0026]...

Embodiment 3

[0030] Example 3: Using glass fiber as the initial raw material, the glass fiber is modified by silane coupling agent KH560 to obtain a surface-active glass fiber reinforcement; the surface of the dried circuit board recycled powder is subjected to active treatment, and then combined with double Phenol A-type epoxy resin (E-54) is mixed to obtain a modified epoxy resin matrix filled with recycled circuit board powder; finally, the glass fiber reinforcement modified by the coupling agent obtained above and recycled circuit board powder are filled The modified epoxy resin matrix is compounded in a certain way to obtain a glass fiber reinforced epoxy resin composite material modified by recycled circuit board powder.

[0031] Step (1): Weigh 100g of dry glass fiber, immerse the dry glass fiber in silane coupling agent KH560 at 40°C for 3 hours, take it out, and dry it at 80°C for 4 hours to obtain a surface-coated coupling agent Modified glass fiber reinforcement;

[0032] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com