Method for synthesizing polycarboxylic acid high-property water reducer by copolymerization of amidated active monomers

A technology of amidation reaction and copolymerization reaction, which is applied in the field of polycarboxylate high-performance water reducer, can solve the problems of poor dispersion retention, reduce the dependence on preparation methods, reduce production costs, and increase market competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

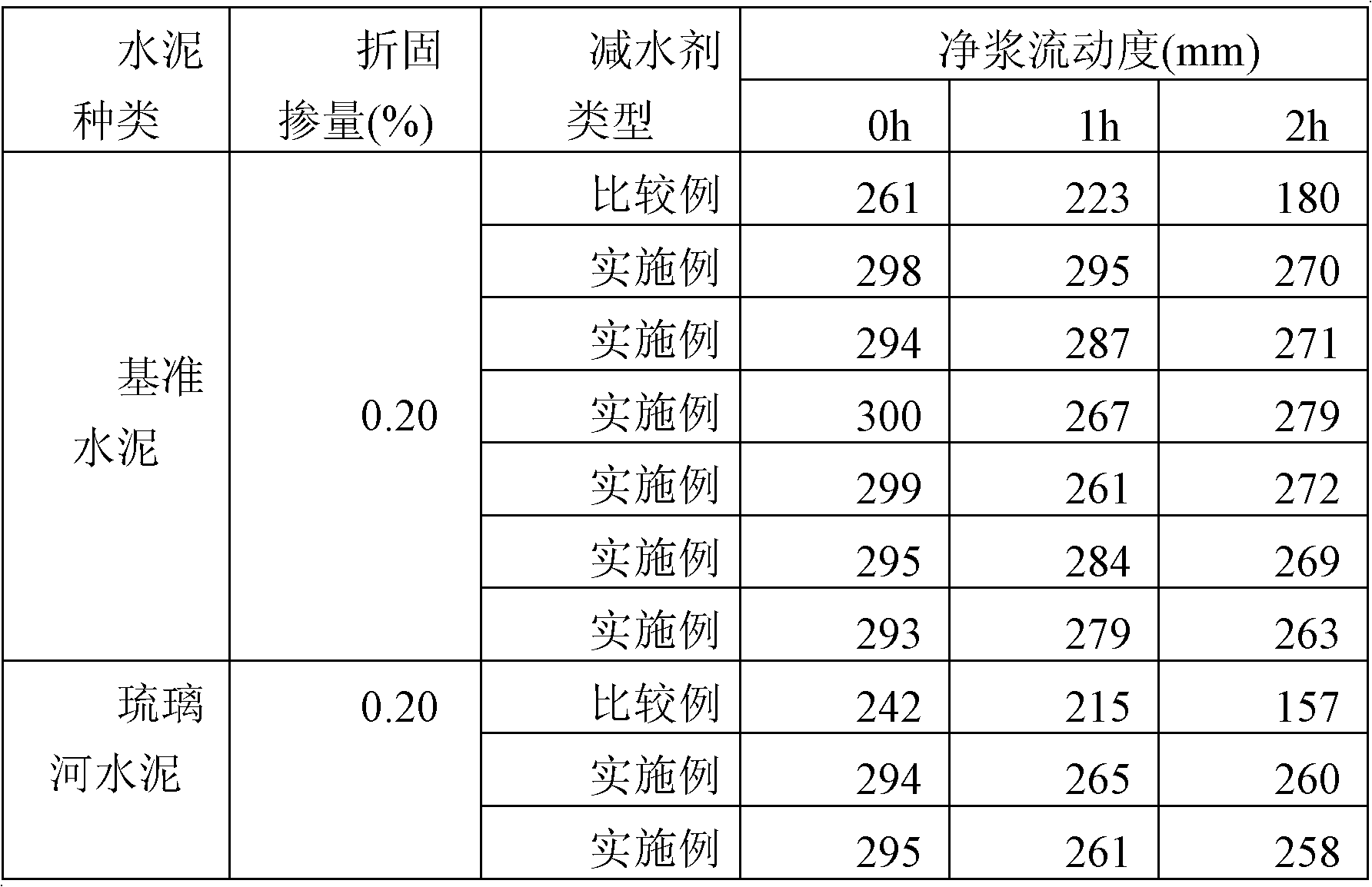

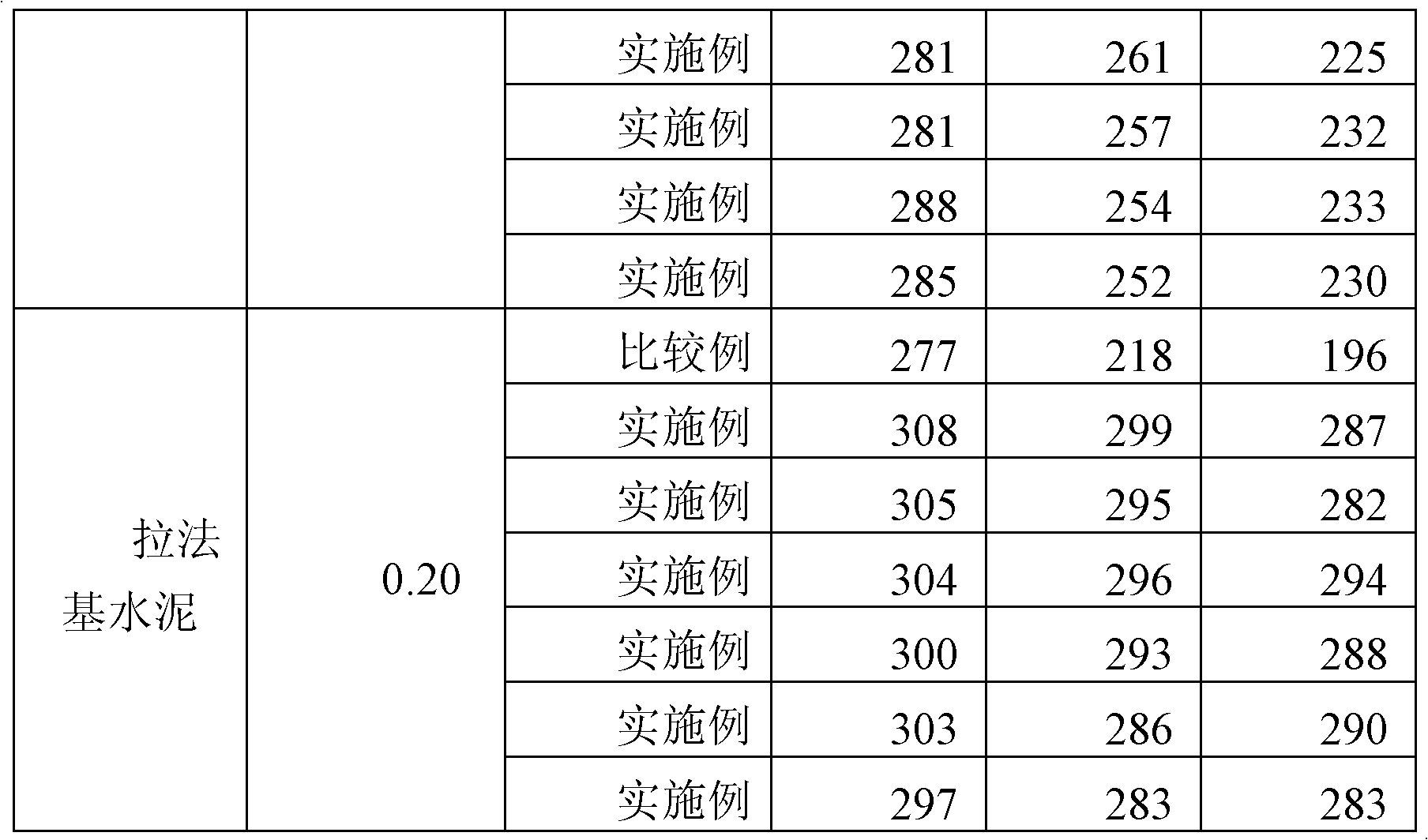

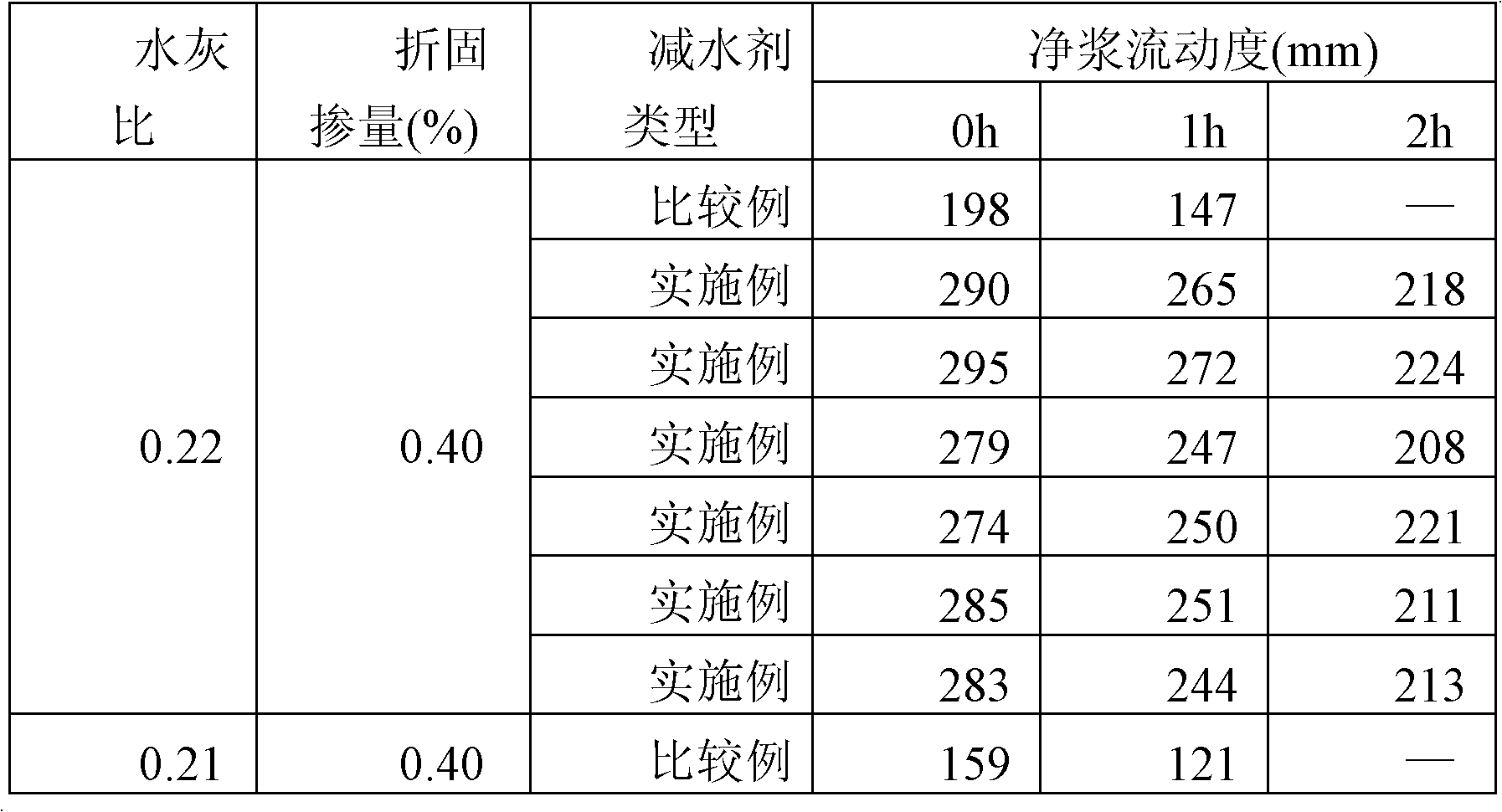

Examples

Embodiment 1

[0022]120g of amino-terminated polyoxyethylene ether (molecular weight: 2000) was added into the reactor, and when the temperature was raised to 50°C, 0.26g of hydroquinone methyl ether, 12.96g of acrylic acid, 1.84g of concentrated sulfuric acid (concentration of 98 %), and the stirring time of each feeding interval was 10 minutes, when the temperature was raised to 80°C, 26.59g hexanaphthene was added, and the temperature was continued to be raised to 145°C to carry out the amidation reaction, and the reaction obtained water was separated during the reaction, and the reaction 6 After one hour, the cyclohexane was removed by vacuuming to obtain the acryloyl polyoxyethylene ether amine, the product of the amidation reaction; , heat up to 60°C and stir for 20 minutes until it is evenly mixed, then add 6.48g of acrylic acid, 2.76g of mercaptoacetic acid, and 92.24g of potassium persulfate solution with a mass fraction of 15% to the reactor, and stir for 10 minutes between each fe...

Embodiment 2

[0024] The polycarboxylate superplasticizer with a concentration of 45% obtained in Example 1 was stored at 6° C. for 40 days, and its implementation effect was measured.

Embodiment 3

[0026] 180g amino-terminated polyoxyethylene ether (molecular weight is 3000) is added in the reactor, when heating up to 80 ℃, add 0.39g hydroquinone, 7.74g methacrylic acid, 9g phosphoric acid successively in the reactor, and each time Stirring time between additions is 20 minutes. When the temperature rises to 100°C, add 15.02g of toluene, and continue to heat up to 160°C for amidation reaction. During the reaction, the water obtained from the reaction is separated, and the toluene is removed by vacuuming after 2 hours of reaction. , to obtain the amidation reaction product isoacryloyl polyoxyethylene ether amine; add the product isoacryloyl polyoxyethylene ether amine obtained from the above amidation reaction into the reactor, then add 201.51g of water, heat up to 50°C and stir for 30 minutes Treat that it is mixed evenly, add the mixture of 12.9g methacrylic acid and 1.95g itaconic acid, 0.64g mercaptopropionic acid, 6.72g mass fraction to the reactor successively and be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com