Ternary mixed solvent with high boiling point and low freezing point and application thereof

A low freezing point, high boiling point technology, applied in the field of electrochemistry, can solve the problems of inability to be used alone, poor low temperature performance of capacitors, low freezing point, etc., to achieve the effect of no abnormal appearance, stable performance, and low freezing point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

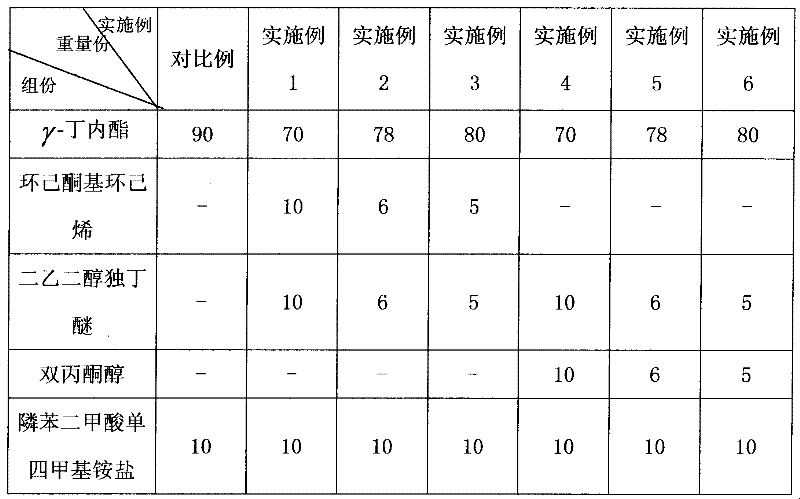

[0026] Adopt four kinds of compounds of gamma-butyrolactone, cyclohexanone cyclohexene, diethylene glycol monobutyl ether, and diacetone alcohol to prepare respectively 90 parts by weight of electrolyte solvent according to the formula in Table 1, and then 90 parts by weight The electrolytic solution solvent and 10 parts of monotetramethylammonium phthalate are proportioned to form an electrolytic solution.

[0027] Raw material composition part and parts by weight of the embodiment of table 1

[0028]

[0029] "-" in the table means no

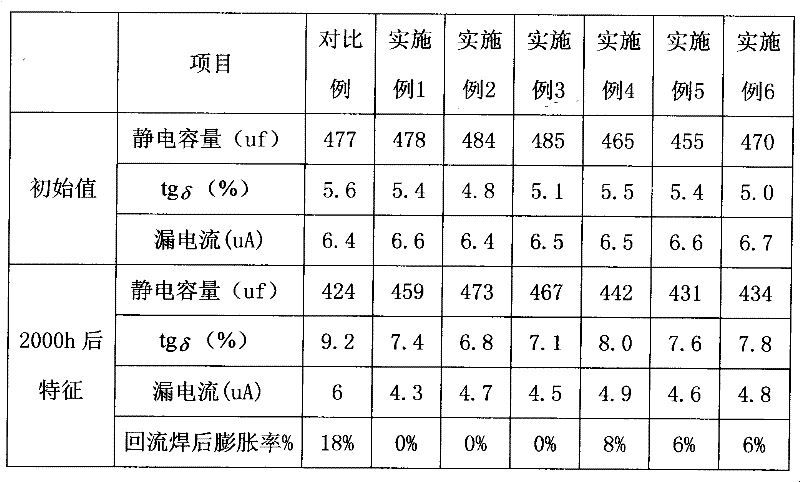

[0030] Fifty aluminum electrolytic capacitors of 10V / 470μf were made by using the electrolytic solutions obtained in Comparative Examples and Examples 1-6, and the performance was first tested at 20°C ambient temperature; Test performance after hours. Test performance includes: electrostatic capacitance, loss value tgδ, leakage current, etc. The average value of the detection data of 50 aluminum solution capacitors in the comparative ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com