Creep permeation full-distance coupling test system for broken rock sample

A test system and rock sample technology, applied in the direction of permeability/surface area analysis, using stable tension/pressure to test material strength, measuring devices, etc., can solve the problems that cannot meet the requirements of broken rock creep penetration test and data acquisition and analysis , small water injection capacity of the supercharger, discontinuity in the seepage process, etc., to achieve the effect of flexible assembly, reliable performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

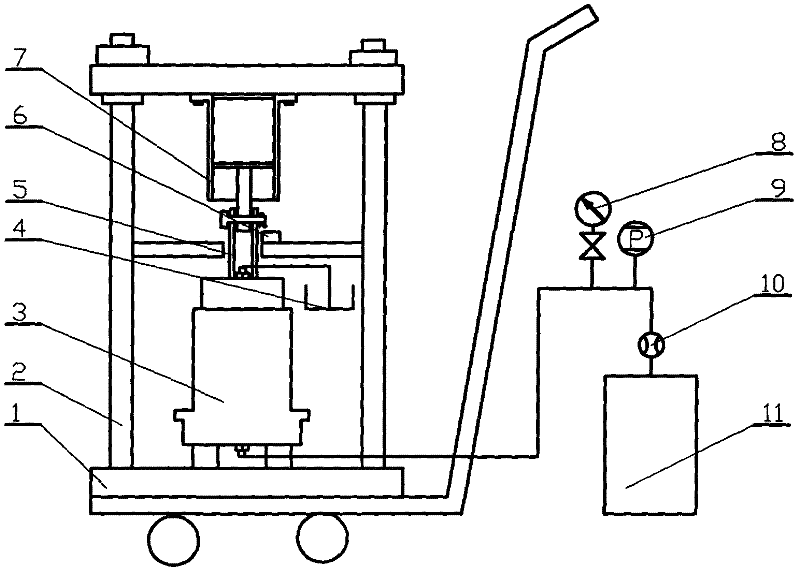

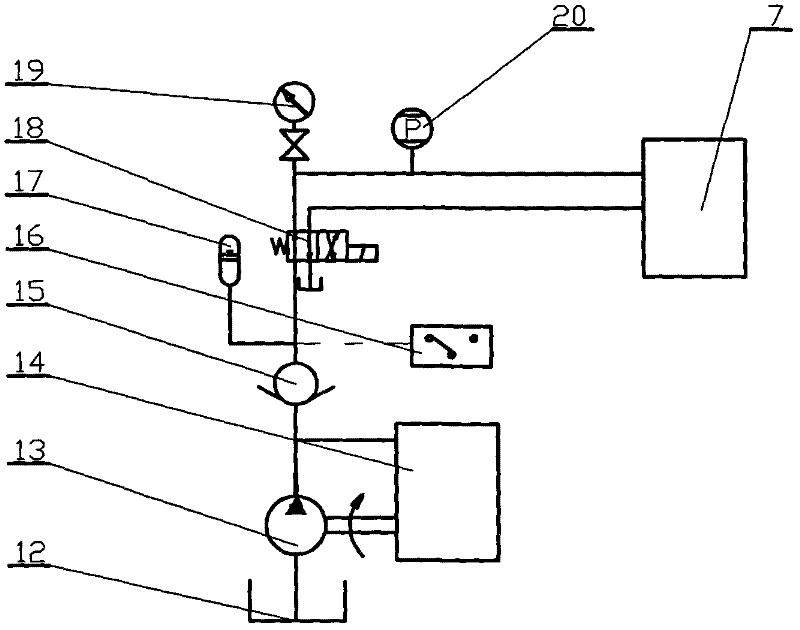

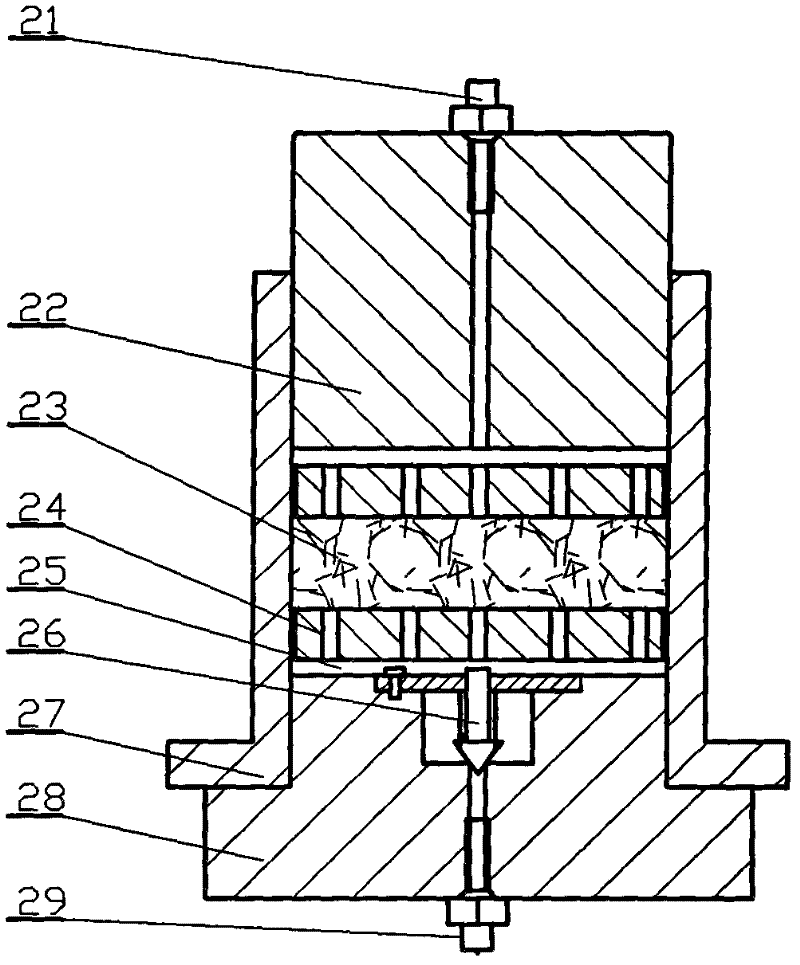

[0022] In the accompanying drawings, the whole coupling test system for creep and penetration of broken rock samples includes an axial pressurization system, a penetration system, data display and monitoring devices; the test system has a flat trolley 1 with rollers at the bottom, A square frame-shaped support 2 is fixedly installed on the bottom plate of the trolley 1; in the support 2, a hydraulic axial pressurization system is fixedly installed on the upper part, and a permeation system is installed on the lower part; the axial pressurization system has a 2. A hydraulic cylinder 7 fixedly connected to the top surface. The bottom end of the hydraulic cylinder 7 is vertically fixedly connected with a hollow tube 5 for axial loading, and a displacement gauge 6 is provided on one side of the hollow tube 5; the permeation system has A vertical cylinder 3, the bottom of the cylinder 3 is fixed with a sealed base 28, the top of the cylinder 3 is fitted with a piston 22, the top sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com